Preparation of nitrogen-modified carbon-supported noble metal hydrogenation catalysts and their application in the hydrogenation of nitrobenzene compounds

A technology of hydrogenation catalyst and nitrobenzene, which is applied in the direction of catalyst activation/preparation, amino compound preparation, organic compound preparation, etc. It can solve the problems of unfriendly environment and achieve the effect of simple preparation and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

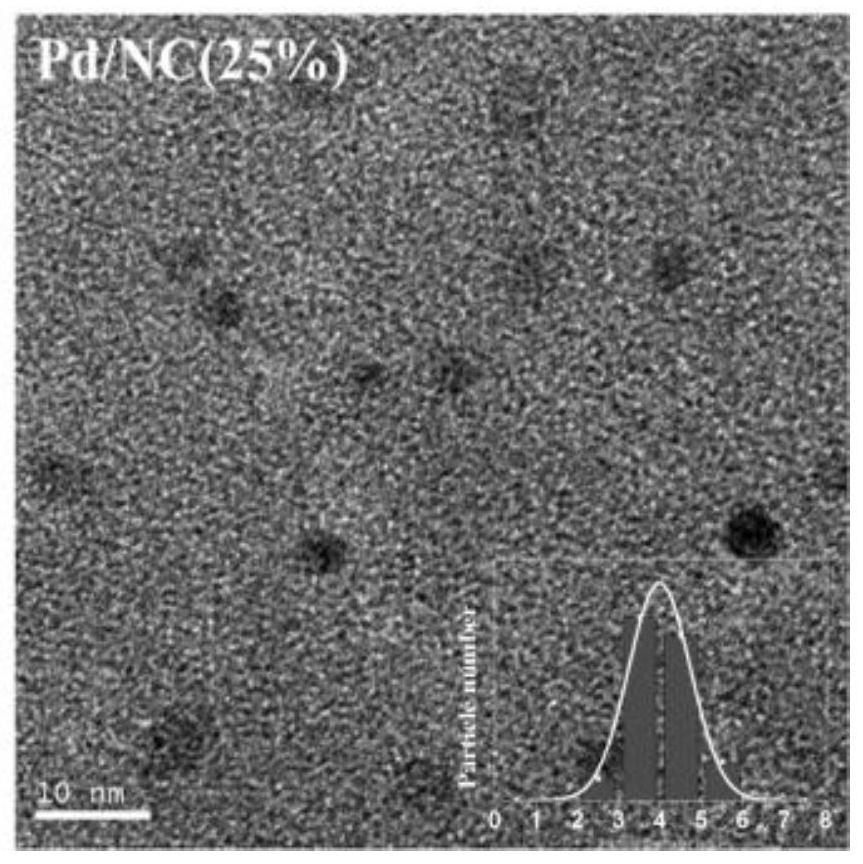

Image

Examples

Embodiment 1-6

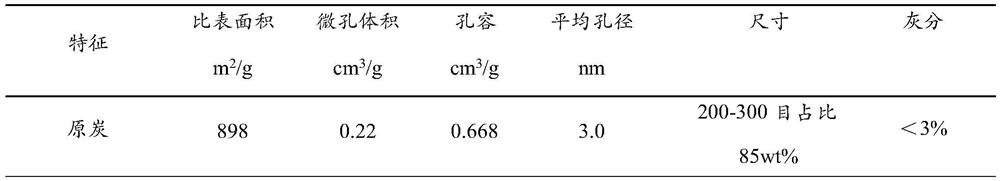

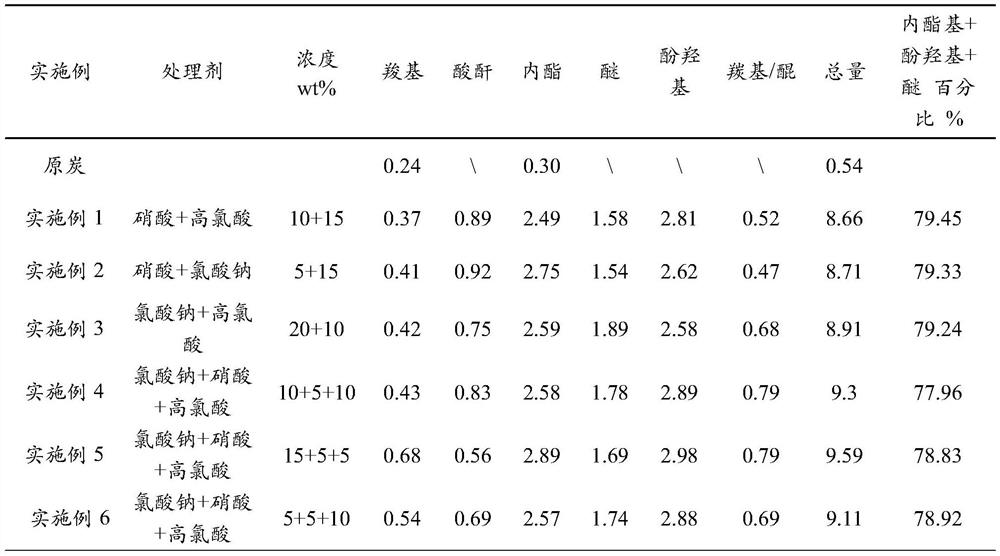

[0042] Embodiment 1-6: activated carbon pretreatment

[0043] Evenly disperse 1.0g of activated carbon into 25.0mL of treatment agent solution, put its suspension in a 50mL round bottom flask, and gradually raise the temperature to 50°C under constant stirring with a magnetic stirrer at a constant temperature for 10 hours, during which time it will be condensed and condensed with alkali The liquid absorbs the exhaust gas. Then, the suspension was cooled to room temperature, filtered with suction, washed with deionized water several times until the pH value was neutral, and then placed in a vacuum oven at 110° C. for 5 h.

[0044] The obtained samples were obtained from literature ((a) J.L.Figueiredo, M.F.R.Pereira, M.M.A.Freitas, J.J.M.Orfao, Carbon 1999, 37, 1379-1389; (b) J.Xu, J.Zhao, J.Xu, T.Zhang, X. Li, X.Di, J.Ni, J.Wang, J.Cen, Ind Eng Chem Res 2014, 53, 14272-14281; (c) L.M. Jiayun Li, Xiaoian Li, Chunshan Lu, and Huazhang Liu, Ind.Eng .Chem.Res 2005,44,5478-5482; (...

Embodiment 7

[0050] 1) Normalized selective treatment of carbon surface groups

[0051] Evenly disperse 1.0g of activated carbon into 25.0mL of 20wt% oxidation treatment reagent (5wt% nitric acid + 15wt% sodium chlorate) solution, place its suspension in a 50mL round-bottomed flask, and keep stirring with a magnetic stirrer at a constant temperature Gradually raise the temperature to 35°C for 5 hours, during which the condensation is circulated and the tail gas is absorbed with lye. Then, the suspension was cooled to room temperature, filtered with suction, washed with deionized water several times until the pH value was neutral, and then placed in a vacuum oven at 110°C for 5 hours.

[0052] 2) Condensation reaction to prepare nitrogen-modified carbon

[0053] Dissolve 10 g of hexamethylenediamine in 30 mL of deionized water, gradually add 1.0 g of activated carbon obtained in step 1) under stirring, and after magnetically stirring for 2 hours, transfer to a 50 mL stainless steel hydroth...

Embodiment 22

[0074] Add 100g of nitrobenzene and 0.05g of the catalyst of Example 7 into a 500mL autoclave, close the autoclave, replace the air in the reactor with nitrogen, then replace the nitrogen with hydrogen, start stirring, the stirring speed is 1400r / min, and maintain the reaction The temperature is 50°C, and the hydrogen pressure is 1.0 MPa to carry out the reaction. When the nitrobenzene content was detected to be 0 by chromatography, the reaction was stopped and the catalyst was filtered. The filtrate is the product after phase separation, water separation and dehydration by vacuum distillation. Quantitative analysis (molar percentage) by chromatography shows that the conversion rate of hydrogenation reaction is 100%, and the selectivity is 100%. The reaction time is 25min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com