A kind of coal tar heavy oil hydrogenation catalyst and preparation method thereof

A heavy oil hydrogenation and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, hydrocarbon oil cracking, etc., can solve the problems of overall dispersibility and low catalytic active components, and achieve the effect of improving overall dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

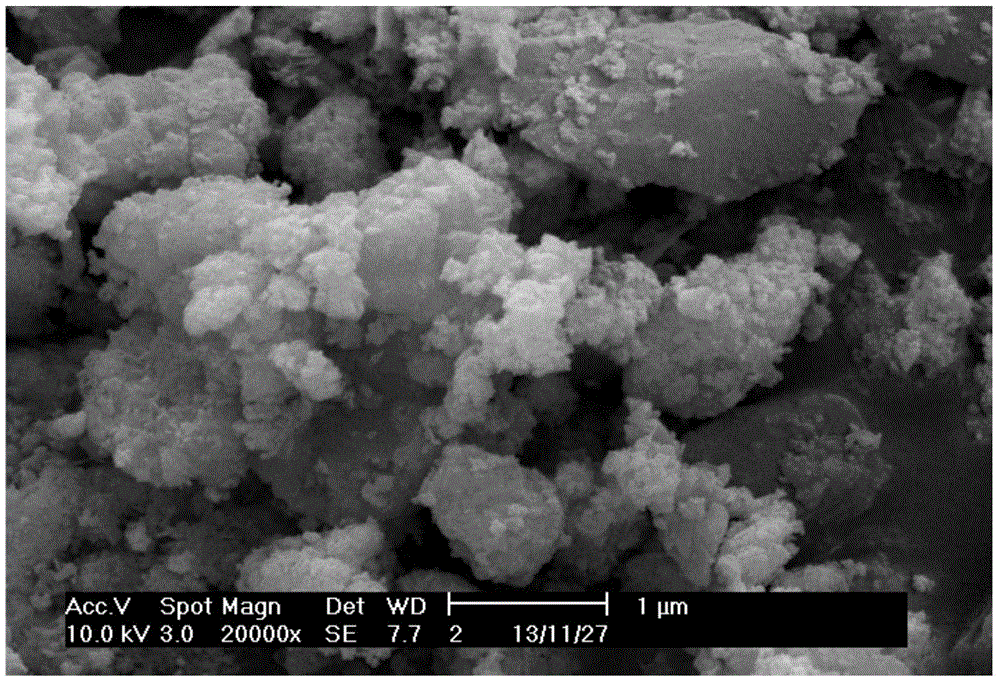

[0034] This embodiment provides a coal tar heavy oil hydrogenation catalyst, its composition includes a carrier and an active component, the carrier is micron-sized bituminous coal, and the active component is iron sulfide, iron oxide and ammonium molybdate, wherein the carrier The content of iron sulfide is 46.09wt%, the content of iron sulfide is 7.68wt%, the content of iron oxide is 46.09wt%, the content of ammonium molybdate is 0.13wt%, the content of molybdenum is 0.05wt%, and the balance is impurities.

[0035] The content of iron in the catalyst=46.09wt%*50%+7.68%*50%=26.885%.

[0036] Described coal tar heavy oil hydrogenation catalyst adopts following method to prepare:

[0037] (1) Add 50g of natural pyrite nano-powder and 300g of marcasite nano-powder to 300g of micron bituminous coal, mix well, then add 0.875g of ammonium molybdate (actually add 4.375g of molybdic acid with a concentration of 20wt% ammonium aqueous solution), and then add water to obtain a slurry ...

Embodiment 2

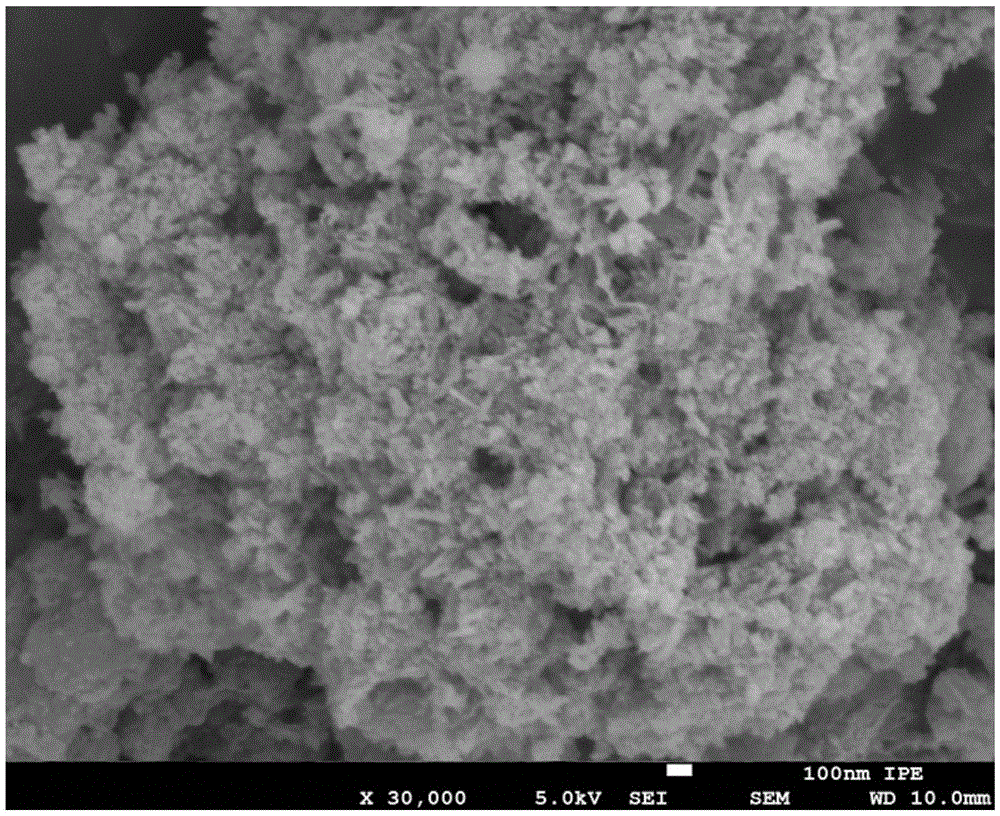

[0040] This embodiment provides a coal tar heavy oil hydrogenation catalyst, its composition includes a carrier and an active component, the carrier is micron-sized bituminous coal, and the active component is iron sulfide, iron oxide and molybdenum ore powder, wherein the carrier The content of iron sulfide is 45.42wt%, the content of iron sulfide is 7.57wt%, the content of iron oxide is 45.42wt%, the content of molybdenum ore powder is 1.59wt%, and the balance is impurities.

[0041] The content of iron in the catalyst=45.42wt%*50%+7.57%*50%=26.495%.

[0042] Described coal tar heavy oil hydrogenation catalyst adopts following method to prepare:

[0043] (1) Add 50g of natural pyrite nanometer and 300g of iron oxide ore powder to 300g of micron-sized bituminous coal, mix well, add 10.5g of molybdenum ore powder, the mass of molybdenum is 5% of the mass of Fe, and then add water , to obtain a solid content of 40wt% slurry;

Embodiment 3

[0046] This embodiment provides a coal tar heavy oil hydrogenation catalyst, its composition includes a carrier and an active component, the carrier is micron-sized bituminous coal, and the active component is iron sulfide, iron oxide, molybdenum ore powder, and nickel ore powder , cobalt ore powder, wherein, the content of carrier is 42.25wt%, the content of iron sulfide is 14.08wt%, the content of iron oxide is 42.25wt%, the content of molybdenum ore powder is 0.845wt%, the content of described nickel ore powder is 0.1wt%, the content of cobalt ore powder is 0.1wt%, and the balance is impurities.

[0047] The content of iron in the catalyst=42.25t%*50%+14.08%*50%=28.165%.

[0048] Described coal tar heavy oil hydrogenation catalyst adopts following method to prepare:

[0049] (1) Add 100g of natural pyrite ore micron powder and 300g of iron oxide ore powder to 300g of micron bituminous coal, mix well, add 6g of molybdenum ore powder, 1g of nickel ore powder and 1g of cobalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com