Concrete dam body drainage blind tube construction method

A technology for concrete dams and drainage blind pipes, which is applied in soil drainage, construction, application, etc., to achieve the effects of convenient construction, quality assurance, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased.

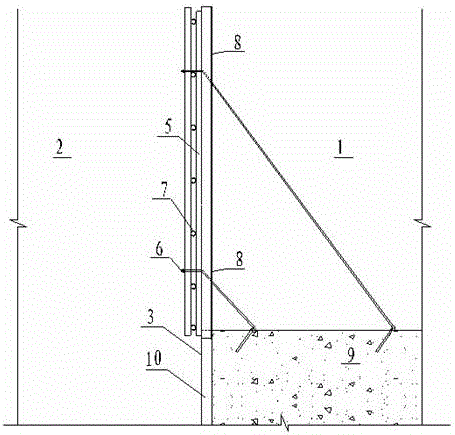

[0020] A kind of concrete dam body drainage blind pipe construction method of the present invention is as follows:

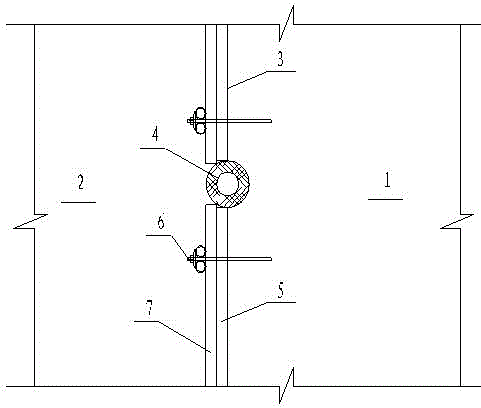

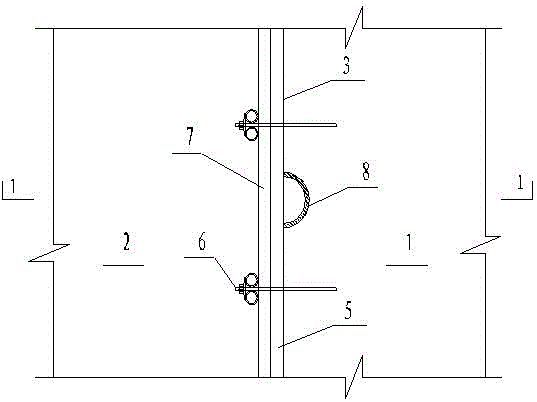

[0021] 1) Make the semicircular pipe 8 according to the design diameter of the blind drainage pipe 4. The semicircular pipe 8 is made of hard materials such as steel pipe or plastic pipe to meet the strength and rigidity of concrete extrusion. The length of the half pipe is made according to the height of the concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com