High-altitude demounting and modifying method of jacking platform

A technology for lifting platforms and tower cranes, applied in construction, cranes, building structures, etc., can solve the problems of long occupation time and great danger of tower cranes, and achieve the effect of reducing potential safety hazards, avoiding influence and reducing occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

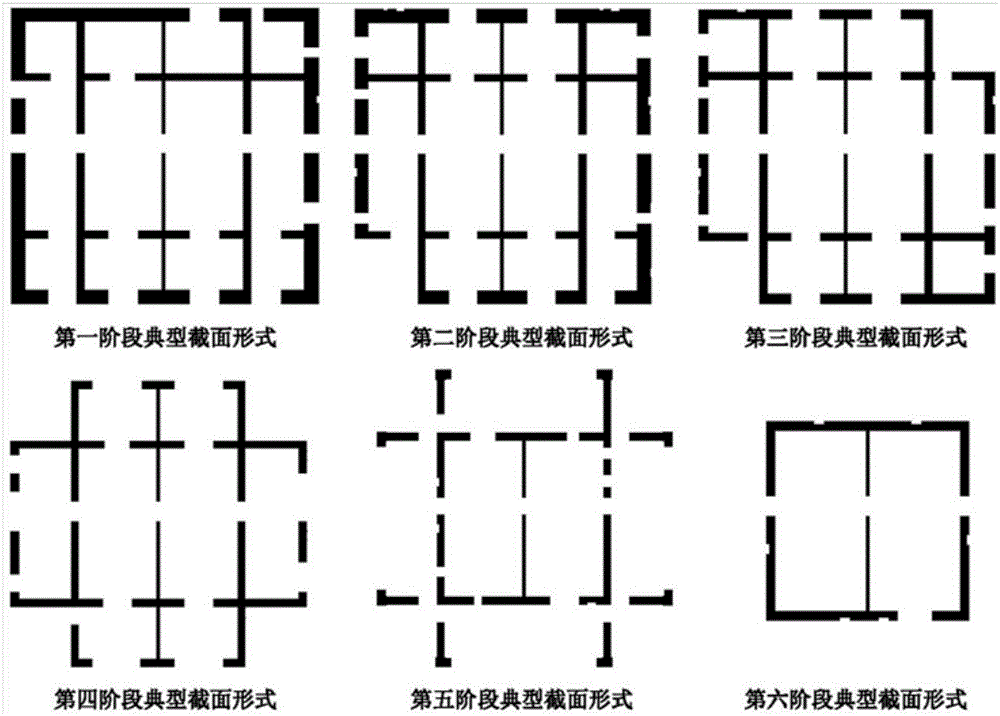

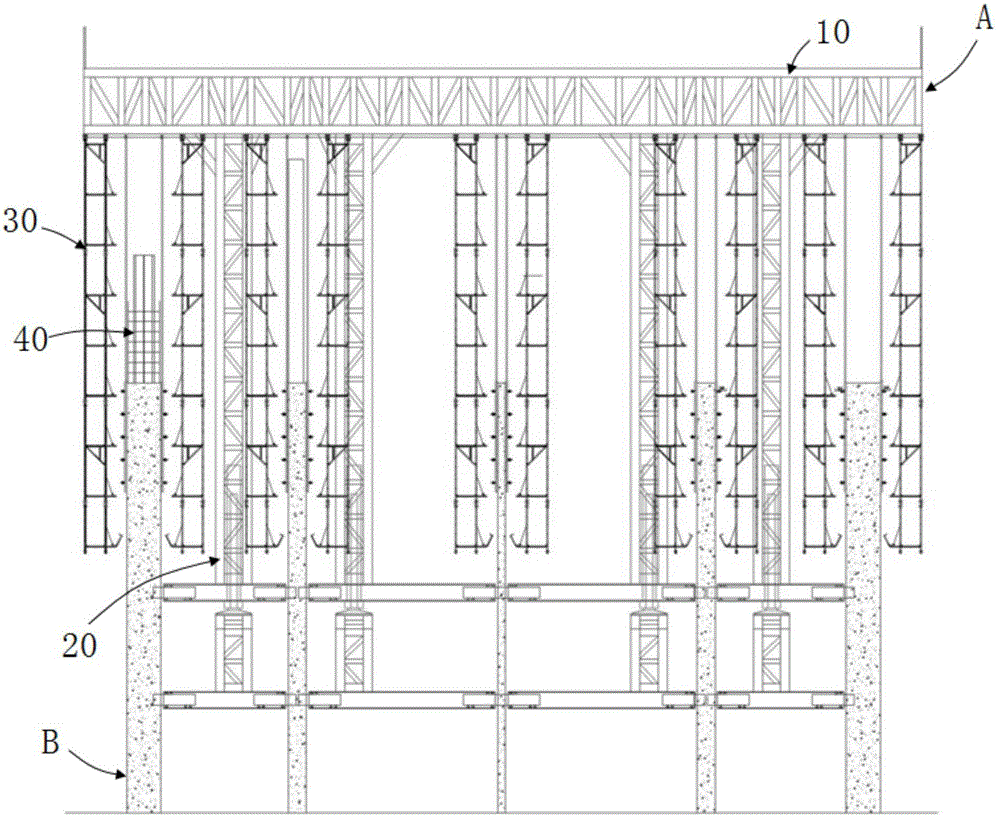

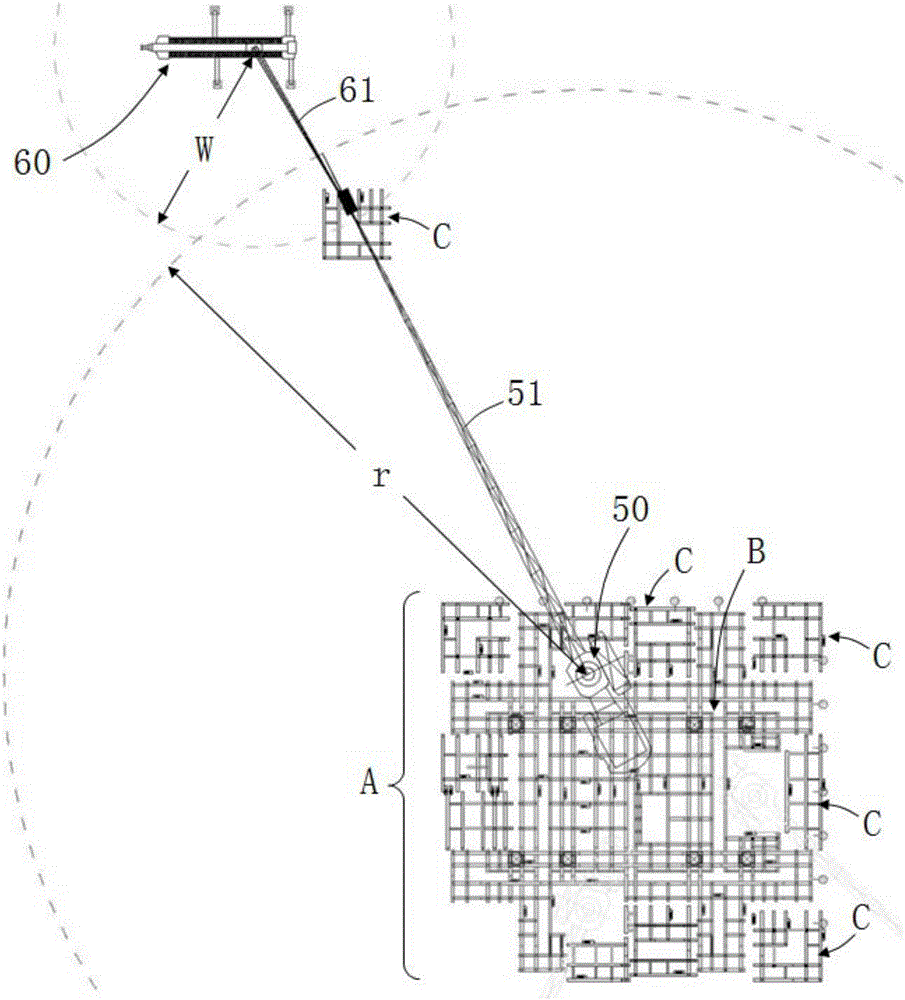

[0033] see Figure 2 to Figure 4 , indicating that the present invention provides a method for dismantling and modifying a jacking platform at high altitude.

[0034] Such as figure 2 As shown, the jacking platform A is set above the core tube B, and the jacking platform A mainly includes a truss system 10, a supporting power system 20, a hanger 30 and a formwork system 40, wherein the truss system 10 is located at the top of the jacking system. At the top of the platform A, the truss system 10 is mainly connected and assembled on the core tube B through the supporting power system 20. The supporting power system 20 is used to support and apply power to lift the jacking platform A up with the core tube B and climbing; the hanger 30 is hung under the truss 10, and the hanger 30 is arranged on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com