Mine underground high-water-permeability filling retaining wall and construction method thereof

A technology of water permeability and mining, which is applied in the direction of filling, mining equipment, earth drilling and mining, etc., can solve the problems of poor water permeability, high cost, high labor intensity, etc., achieve strong water permeability, reduce filling cost, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

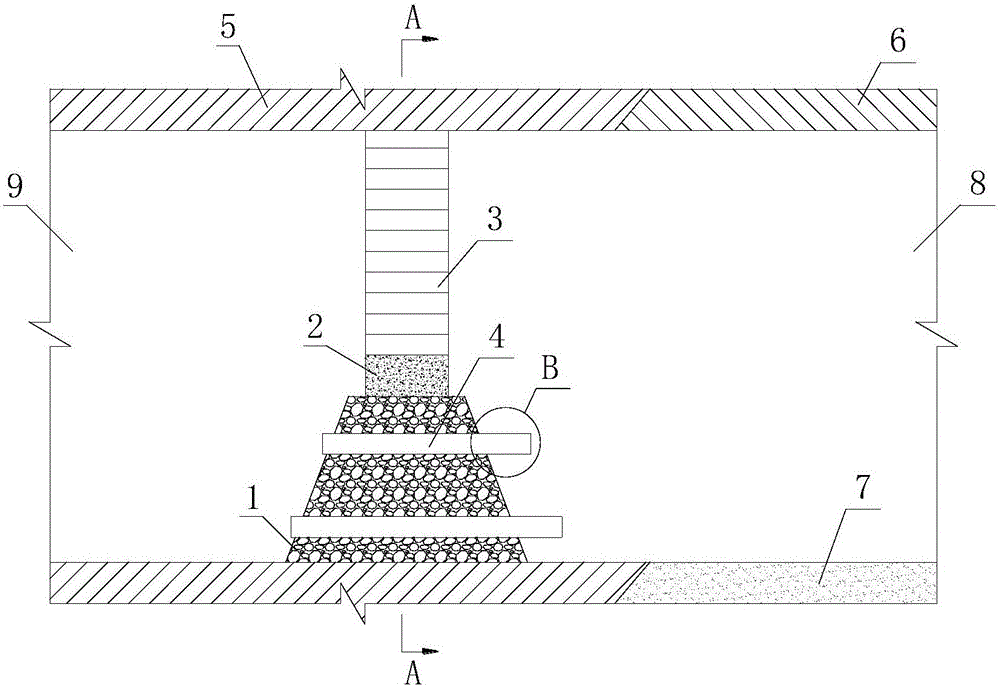

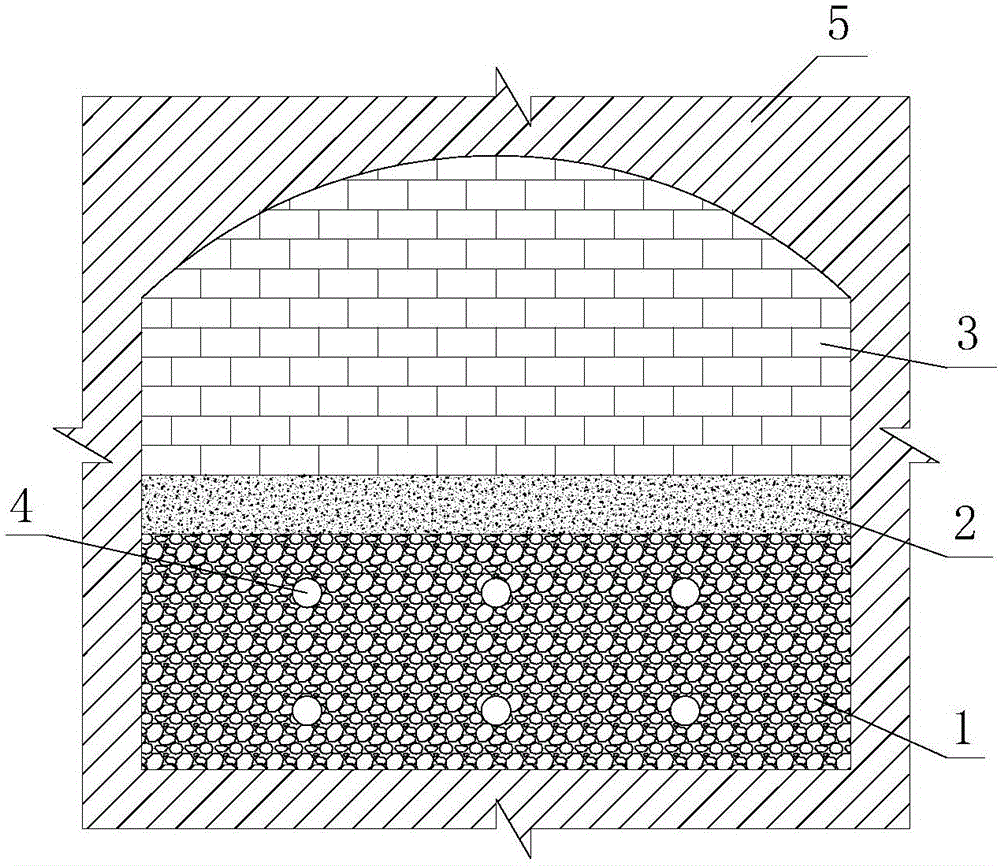

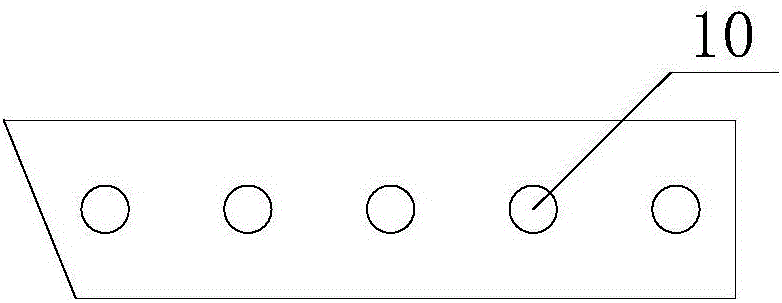

[0041] Embodiment 1: A strong water-permeable filling retaining wall under a mine, including a waste rock layer 1, a permeable concrete layer 2 and a water-permeable brick layer 3 sequentially arranged in the surrounding rock 5, and the waste rock layer 1 is located in the permeable concrete layer 2 At the bottom, several permeable pipes 4 are pre-buried in the waste rock layer 1, the permeable brick layer 3 is located on the top of the permeable concrete layer 2, and the upper part of the permeable brick layer 3 is connected to the surrounding rock 5, the waste rock layer 1, permeable The concrete layer 2 and the permeable brick layer 3 separate the surrounding rock 5 into a port 9 and a goaf 8 . The top of the step-down area 8 is connected to the upper ore body 6 and the surrounding rock 5 , and the bottom of the step-down area 8 is the lower filling body 7 connected to the surrounding rock 5 . The waste rock layer 1 is located at the bottom layer and is composed of waste ro...

Embodiment 2

[0042]Embodiment 2: A strong water-permeable filling retaining wall under a mine, including a waste rock layer 1, a permeable concrete layer 2 and a permeable brick layer 3 arranged in sequence in the surrounding rock 5, and the waste rock layer 1 is located in the permeable concrete layer 2 At the bottom, several permeable pipes 4 are pre-buried in the waste rock layer 1, the permeable brick layer 3 is located on the top of the permeable concrete layer 2, and the upper part of the permeable brick layer 3 is connected to the surrounding rock 5, the waste rock layer 1, permeable The concrete layer 2 and the permeable brick layer 3 separate the surrounding rock 5 into a port 9 and a goaf 8 . The top of the step-down area 8 is connected to the upper ore body 6 and the surrounding rock 5 , and the bottom of the step-down area 8 is the lower filling body 7 connected to the surrounding rock 5 . The waste rock layer 1 is located at the bottom layer and is composed of waste rock produ...

Embodiment 3

[0043] Embodiment 3: A strong water-permeable filling retaining wall under a mine, including a waste rock layer 1, a permeable concrete layer 2 and a permeable brick layer 3 arranged in sequence in the surrounding rock 5, and the waste rock layer 1 is located in the permeable concrete layer 2 At the bottom, several permeable pipes 4 are pre-buried in the waste rock layer 1, the permeable brick layer 3 is located on the top of the permeable concrete layer 2, and the upper part of the permeable brick layer 3 is connected to the surrounding rock 5, the waste rock layer 1, permeable The concrete layer 2 and the permeable brick layer 3 separate the surrounding rock 5 into a port 9 and a goaf 8 . The top of the step-down area 8 is connected to the upper ore body 6 and the surrounding rock 5 , and the bottom of the step-down area 8 is the lower filling body 7 connected to the surrounding rock 5 . The waste rock layer 1 is located at the bottom layer and is composed of waste rock prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com