Steam lock relieving device of steam system drain valve

A steam system and steam trap technology, which is applied in the direction of steam traps, mechanical equipment, etc., can solve the problems of increased drying time, low energy utilization rate, and large steam consumption, so as to reduce steam consumption and improve energy consumption. Utilization rate, the effect of improving the heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

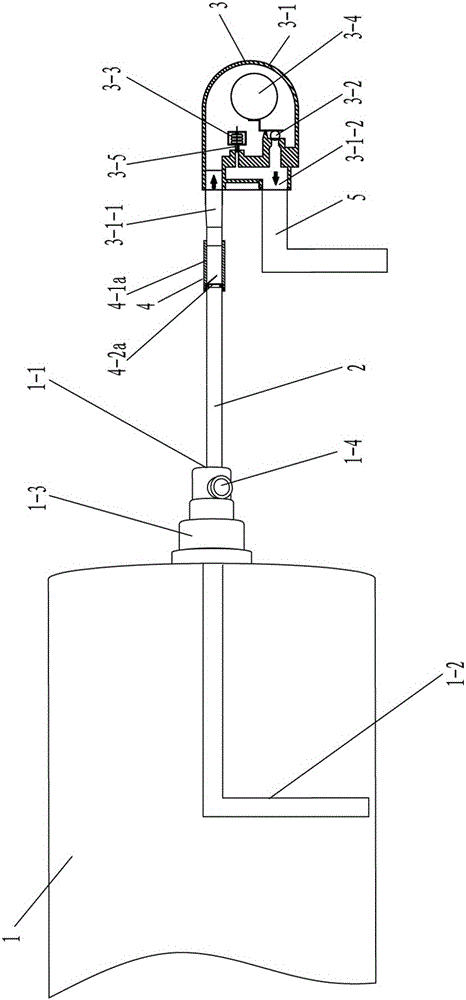

[0029] Such as figure 1 , 5 As shown, a steam system steam trap release steam lock device, including steam drying cylinder 1, siphon 1-2, steam rotary joint 1-3, steam trap 2 and steam trap 3, said steam drying cylinder 1 is equipped with steam rotary Joint 1-3, one end of steam rotary joint 1-3 is connected with one end of siphon pipe 1-2, the other end is connected with one end of drain pipe 2, and one end of drain pipe 2 is connected with siphon pipe 1-2 through steam rotary joint 1-1 The other end is connected with the water inlet 3-1-1 of the steam trap 3, the steam trap 3 also has a water outlet 3-1-2, and the steam rotary joint 1-1 has a steam inlet 1-4; A steam lock release mechanism 4 is provided on the pipeline of the pipe 2, and the steam lock release mechanism 4 is arranged between the steam rotary joint 1-3 of the steam drying cylinder 1 and the steam trap 3.

[0030] Such as figure 1 , 5 As shown, the steam lock release mechanism 4 includes a connecting sleev...

Embodiment 2

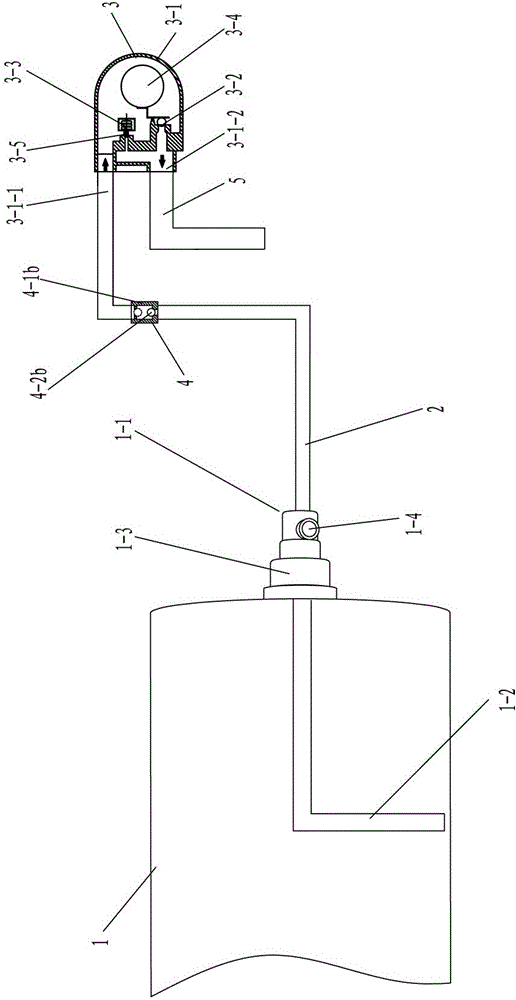

[0036] Such as figure 2 , 6 , 7, the difference between embodiment 2 and embodiment 1 is that: the steam lock release mechanism 4 includes a connecting pipe 4-1b and a sphere 4-2b, and the connecting pipe 4-1b is arranged on the pipe of the drain pipe 2 On the road, and the angle α between the axis OG of the connecting pipe 4-1b and the center of gravity line OQ of the sphere 4-2b is 0°≤α≤85°, and the diameters at both ends of the connecting pipe 4-1b are smaller than the diameter of the sphere 4-2b , The ball 4-2b is located in the connecting pipe 4-1b.

[0037] The working process of embodiment 2 is: when the equipment of steam dryer 1 has just started to work, the internal temperature of the float trap 3 is less than 70 degrees, and the built-in steam lock release device of the float trap 3 is in the enabled state, and its The exhaust valve opens. Since the exhaust valve is open at this time, the steam greater than the atmospheric pressure of the air enters the steam dr...

Embodiment 3

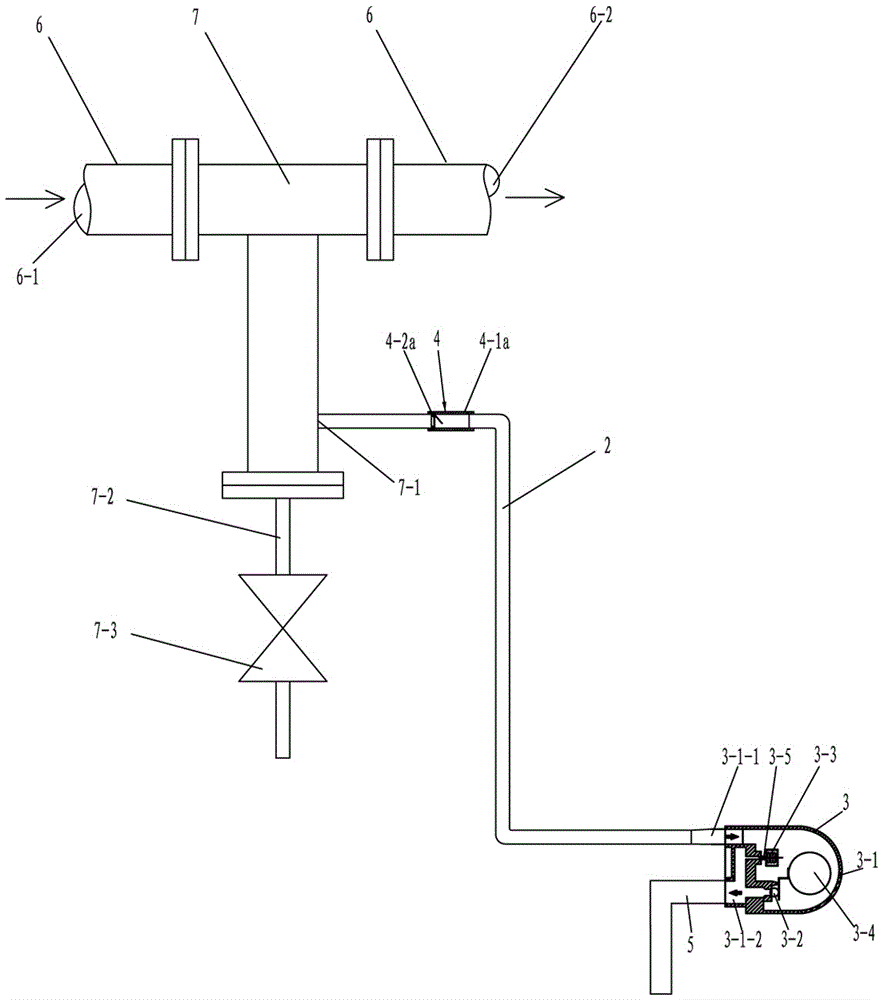

[0040] Such as image 3 , 5 As shown, a device for steam trap release in a steam system has a steam transmission pipeline 6, a pipeline tee 7, a steam trap 2 and a steam trap 3, and the steam trap 3 has a water inlet 3-3-1 and an outlet The water port 3-1-2, the pipeline tee 7 has a drain port 7-1, the water inlet 3-3-1 of the drain valve 3 is connected with one end of the drain pipe 2, and the other end of the drain pipe 2 is connected with the pipeline The drain port 7-1 of the tee 7 is connected, the pipeline of the drain pipe 2 is provided with a steam lock release mechanism 4, and the steam lock release mechanism 4 is provided with a pipeline tee 7 and a steam trap 3 of the steam transmission pipeline 6 between.

[0041] The steam lock release mechanism 4 includes a connecting sleeve 4-1a and a baffle 4-2a, the connecting sleeve 4-1a is arranged on the pipeline of the drain pipe 2, and the baffle 4-2a is arranged on the connecting sleeve 4-1a in the nozzle or pipe, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com