System for detecting sealing performance and searching leak points of motor and controller and using method of system

A sealing performance and controller technology, which can be used in the test of fluid tightness, the test of machine/structural components, and by measuring the acceleration and deceleration rate of fluid, etc. Low efficiency and other problems, to achieve the effect of improving safety performance, simplifying the overall structure, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

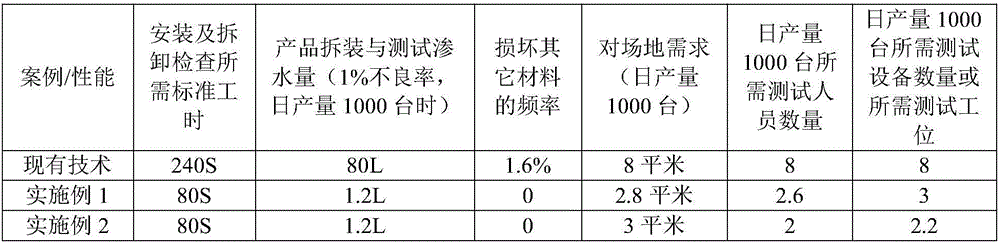

Embodiment 1

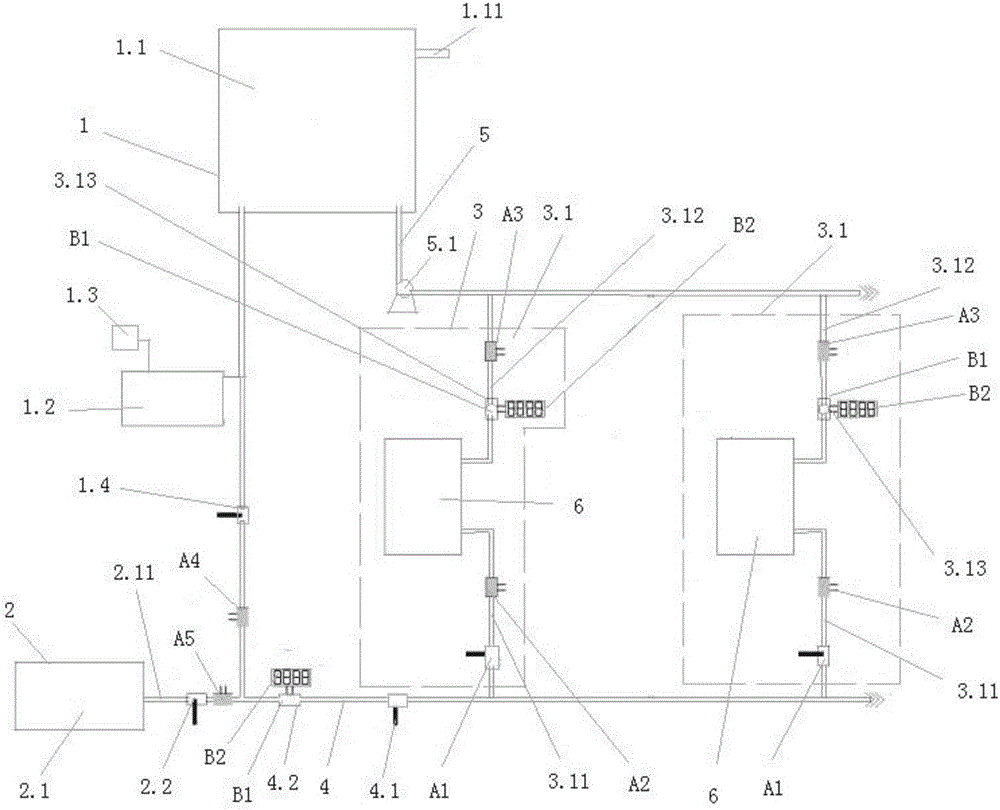

[0038] see figure 2 , a system for detecting the sealing performance of motors and controllers and finding leaks, including a water supply pressure component 1, an air supply component 2, and a test pipeline 4 that communicates with the water supply pressure component 1 and the air pressure component 2 respectively. Part 3 and return line 5.

[0039] The water supply pressure component 1 includes a water storage tank 1.1, a high-pressure water pump 1.2 communicated with the water storage tank 1.1, a motor inverter 1.3 connected to the motor in the high-pressure water pump 1.2, and an outlet pipeline 1.21 arranged on the high-pressure water pump 1.2 The main water channel valve 1.4 on the top. The upper part of the water storage tank 1.1 is provided with an exhaust pipe 1.11.

[0040] The air supply component 2 includes an air compressor 2.1 and a main airway valve 2.2 arranged on the air outlet pipeline 2.11 of the air compressor 2.1.

[0041] The detection unit 3 includes...

Embodiment 2

[0065] A system for detecting the sealing performance of motors and controllers and finding leaks. The difference from Embodiment 1 is that it also includes a PLC controller; the motor in the high-pressure water pump 1.2, the motor frequency converter 1.3, and the main waterway valve 1.4. Air pump in air compressor 2.1, main airway valve 2.2, test valve A1, first solenoid valve A2, second solenoid valve A3, main test valve 4.1, pressure sensor B1, digital display pressure gauge B2, third solenoid The valve A4, the fourth electromagnetic valve A5 and the water delivery pump 5.1 are all connected to the PLC controller.

[0066] A kind of system that is used for the sealing performance detection of motor and controller and leak point of this embodiment is different from Embodiment 1 only in that the above-mentioned components are automatically controlled by the controller (by inserting a program inside the controller to carry out Automatic control) to realize automatic operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com