A method for measuring the mixing ratio of coarse and fine aggregate

A measurement method and mixing ratio technology, which is applied in the field of coarse and fine aggregate mixing ratio measurement, can solve the problems of small penetration distance, high main frequency of radar wave, low main frequency of radar wave, etc., and achieve the goal of reducing mixing time and saving manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

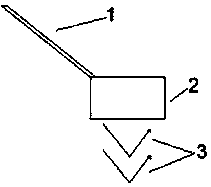

Image

Examples

Embodiment Construction

[0012] The present invention is based on the detection function of the geological radar, and the waveform diagram of the geological radar produced by aggregates with different particle sizes after being fully mixed is obtained through previous experiments, and is reserved as a control group. In the process of engineering construction, when it is necessary to determine whether the mixed aggregate pile on site is evenly mixed, the corresponding waveform diagram is obtained after detection by ground radar, and then compared with the group with similar particle size in the control group, the target bone can be judged. Whether the stockpile is evenly mixed.

[0013] A method for measuring the mixing ratio of coarse and fine aggregates, comprising the following steps:

[0014] 1. Preparation of the control group: Prepare the control group in advance, and separate the aggregates with a particle size of 0mm-120mm into eight piles of bones with mesh diameters of 80mm, 40mm, 20mm, 5mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com