Device for cutting trees

A tree and screw technology, applied in the field of tree cutting devices, can solve the problems of unguaranteed personal safety of staff, high cost of aerial work vehicles, and high limitations of applicable environments, so as to avoid safety accidents, reduce the probability of occurrence, Avoid the effect of undirectional swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

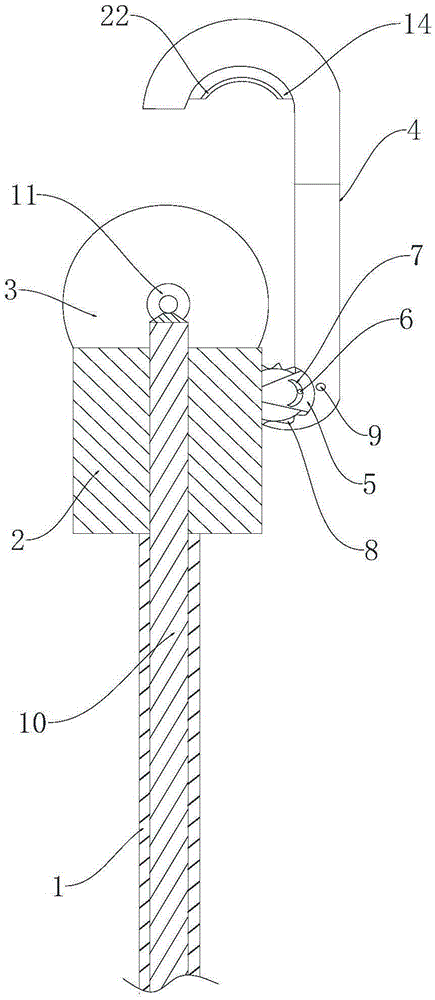

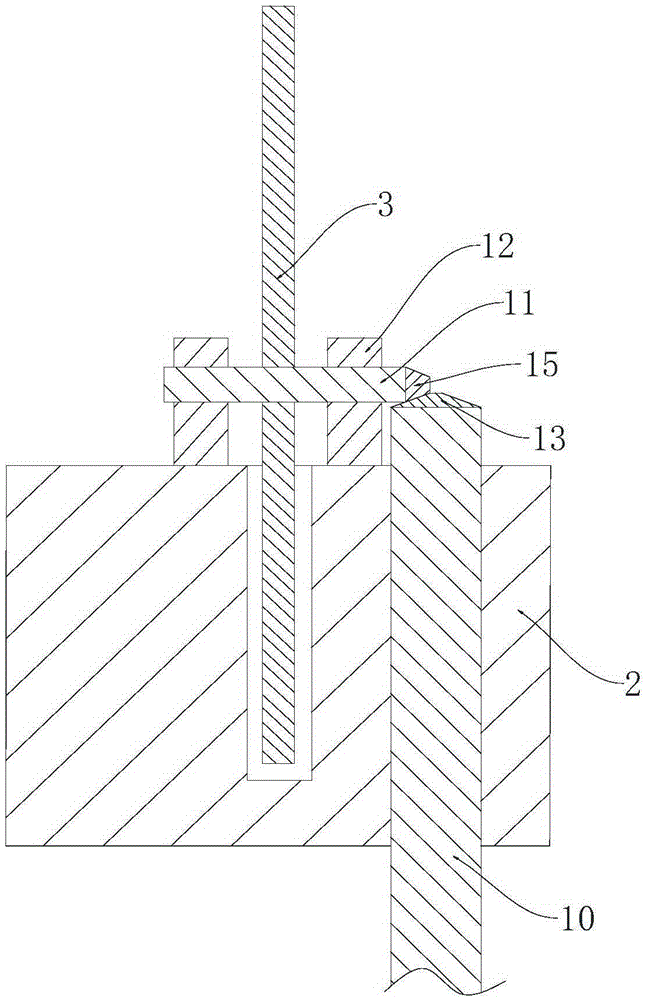

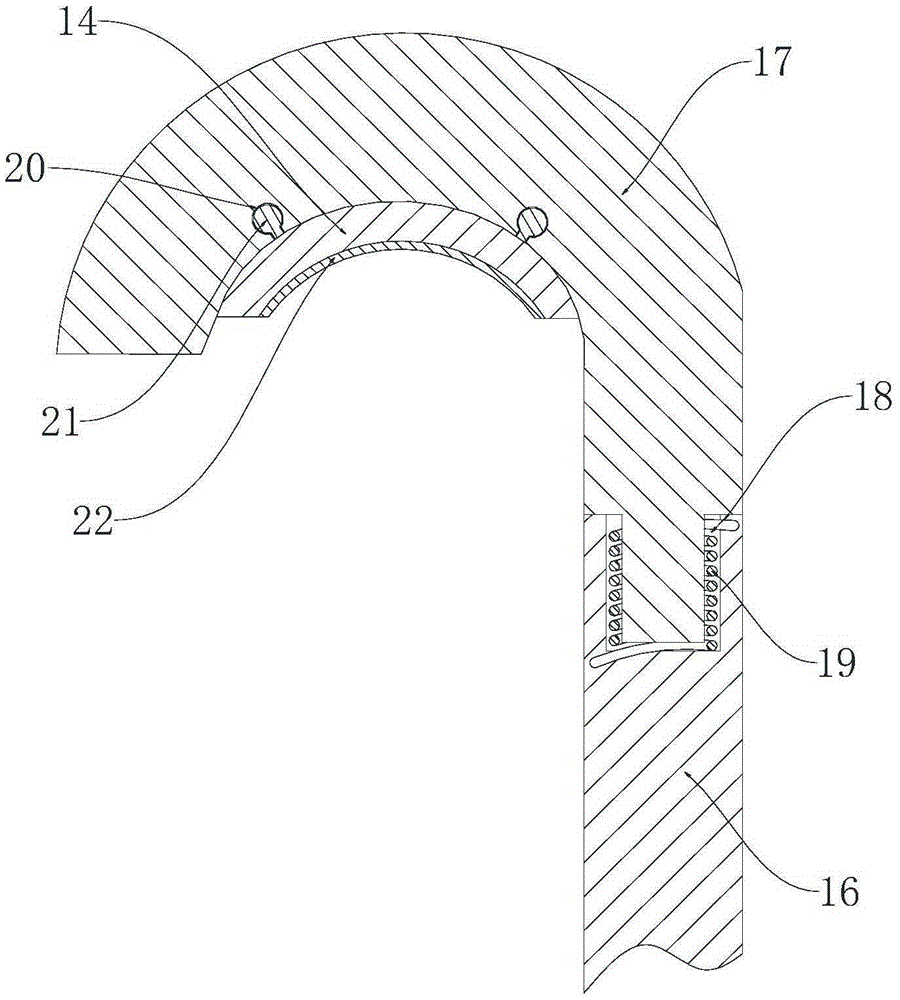

[0025] Such as Figure 1 to Figure 5 As shown, the device for cutting trees includes a screw 10, a cutting base 2 and a cutting assembly. The cutting assembly includes two supporting blocks 12 arranged oppositely and fixedly connected to the upper end surface of the cutting base 2 and rotatingly arranged on the two supporting blocks through bearings. The rotating shaft 11 on 12, the gear saw blade 3 is sleeved on the rotating shaft 11, the lower end of the screw 10 is sleeved with a sleeve 1, the upper end of the screw 10 penetrates the cutting base 2, and the end is installed above the cutting base 2. The bevel gear 13 of the rotating shaft 11 is equipped with a bevel gear 15 matched with the bevel gear 13; it also includes a hanging arm assembly 4, which includes a hanging arm rod 16 mounted on the side wall of the cutting base 2 and The inverted J-shaped hanging arm head 17, the upper end of the arm hanging rod 16 is provided with a recessed receiving groove 18, the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com