Strip steel scrap edge rag control method suitable for rewinding unit circle shear

A control method and disc shearing technology, applied in shearing devices, shearing machine equipment, manufacturing tools, etc., can solve the problem of not taking into account the mutual influence of overlap, gap and shear tension, and improve market competitiveness. , Meet the requirements of trimming quality, and solve the effect of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

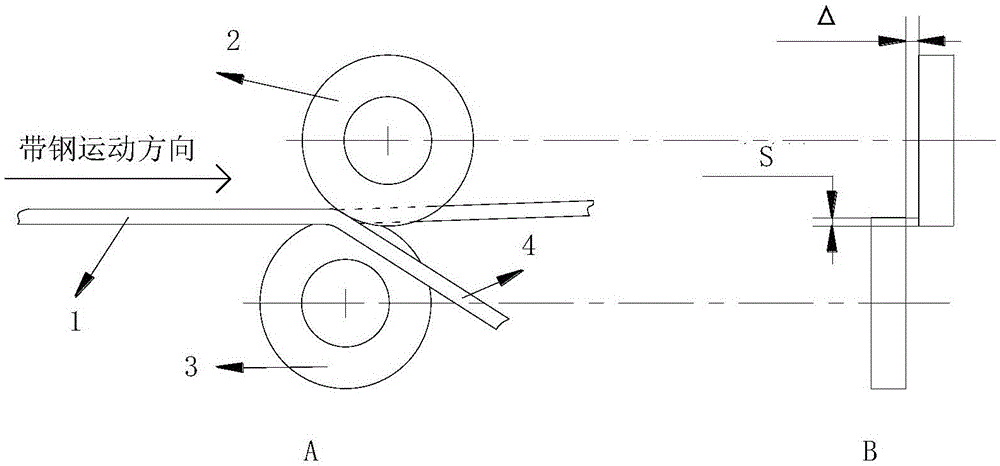

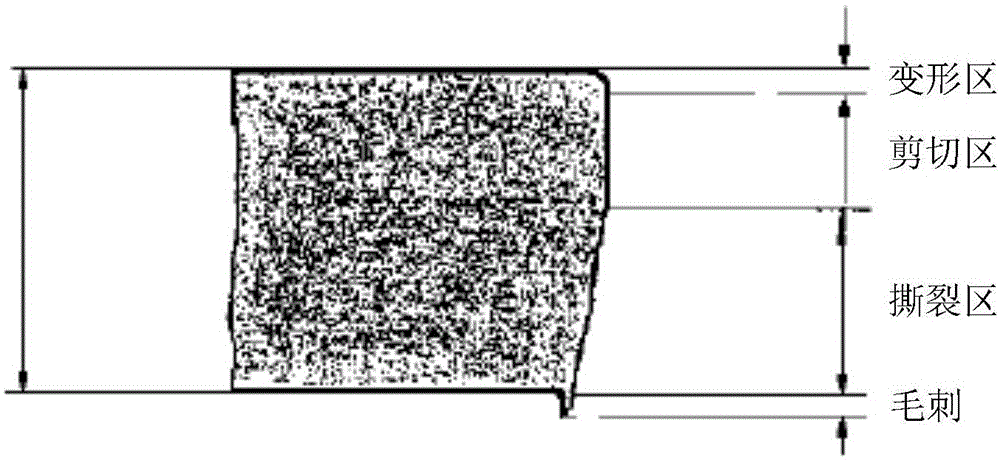

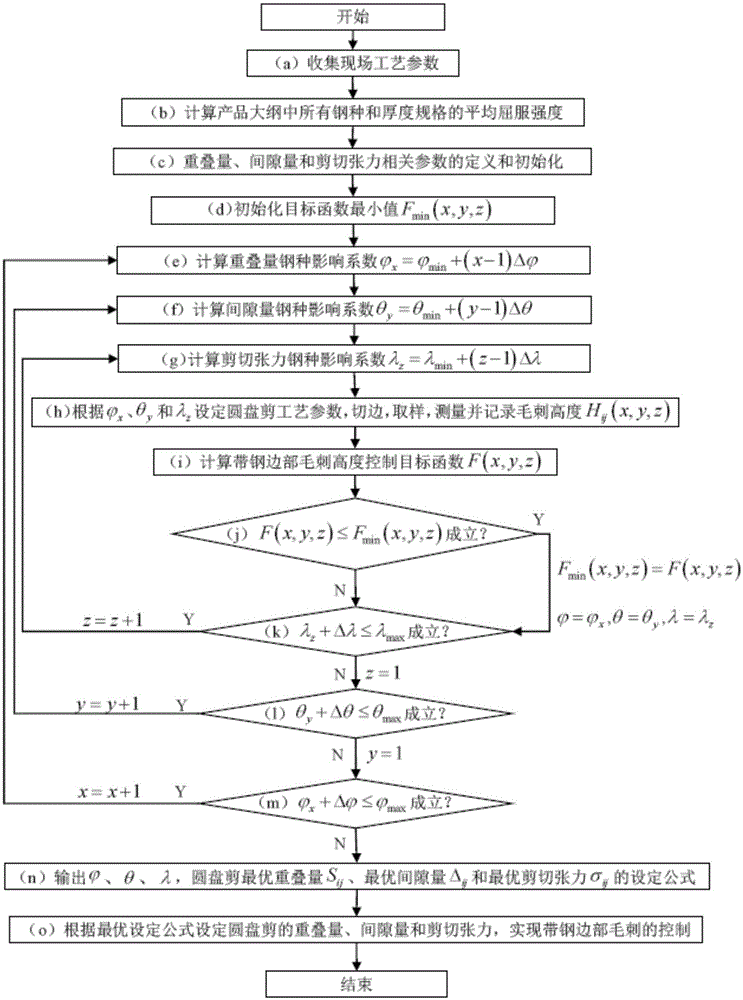

[0022] A strip trimming burr control method applicable to the disc shears of the recoiler unit according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

[0023] Such as image 3 , 4 As shown, a kind of strip trimming burr control method applicable to the disc shears of the recoiling unit of the present invention comprises the following steps carried out successively:

[0024] (a) Collect on-site process parameters, including: collect the number M of steel grades and the number N of thickness specifications in the on-site product outline (that is, a group of steel strips mentioned above); collect the i-th steel type and the j-th thickness Yield strength σ of specification product sij , thickness h ij , the proportion of the steel type and thickness specification in the product outline η ij ; Among them, i is the steel type parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com