Composite spiral fiber spinning apparatus and spinning method thereof

A spinning device and fiber technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of unstable whipping of electrospun fibers, reduced mechanical strength, and large ratio differences, and achieve the realization of Different levels of degradation can be adjusted to ensure durability and improve the effect of hydrophilicity and hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

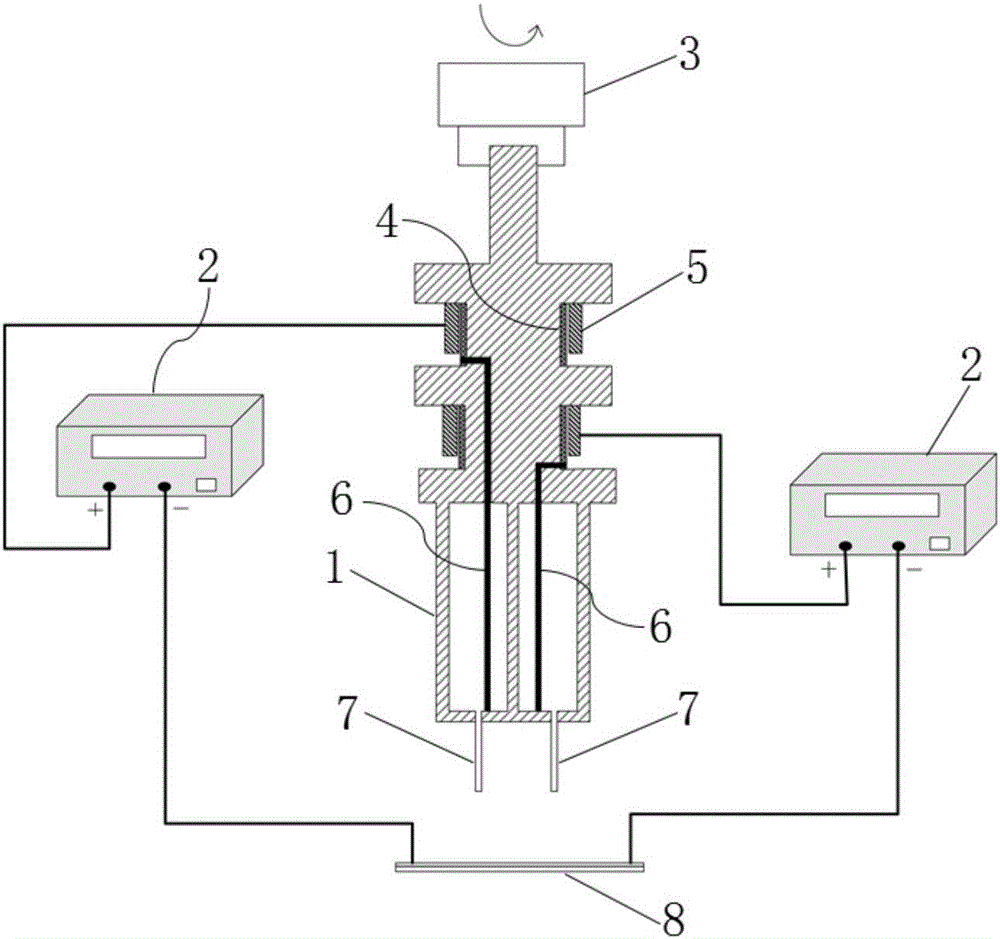

[0045] figure 1 It is a two-component composite helical micro-nano fiber spinning device. In the device, there are two chambers in the insulating liquid storage chamber 1, and the PCL particles are dissolved in dichloromethane, and magnetically stirred at room temperature until the PCL is completely dissolved in dichloromethane. In methane, an electrospinning solution with a mass fraction of 8% was obtained; similarly, PLGA was dissolved in dichloromethane to obtain a spinning solution with a mass fraction of 10%. Close the liquid outlet of the stainless steel nozzle 7, and inject the PCL solution and the PLGA solution into the two chambers respectively. Fix the upper end of the insulating liquid storage chamber 1 to the output end of the motor 3, control the motor speed to 1k ~ 8k RPM, set the voltage of the two ring brushes to 16kV for the PCL solution connection, 12kV for the PLGA solution connection, and the stainless steel nozzle 7 liquid outlet and The distance between ...

Embodiment 2

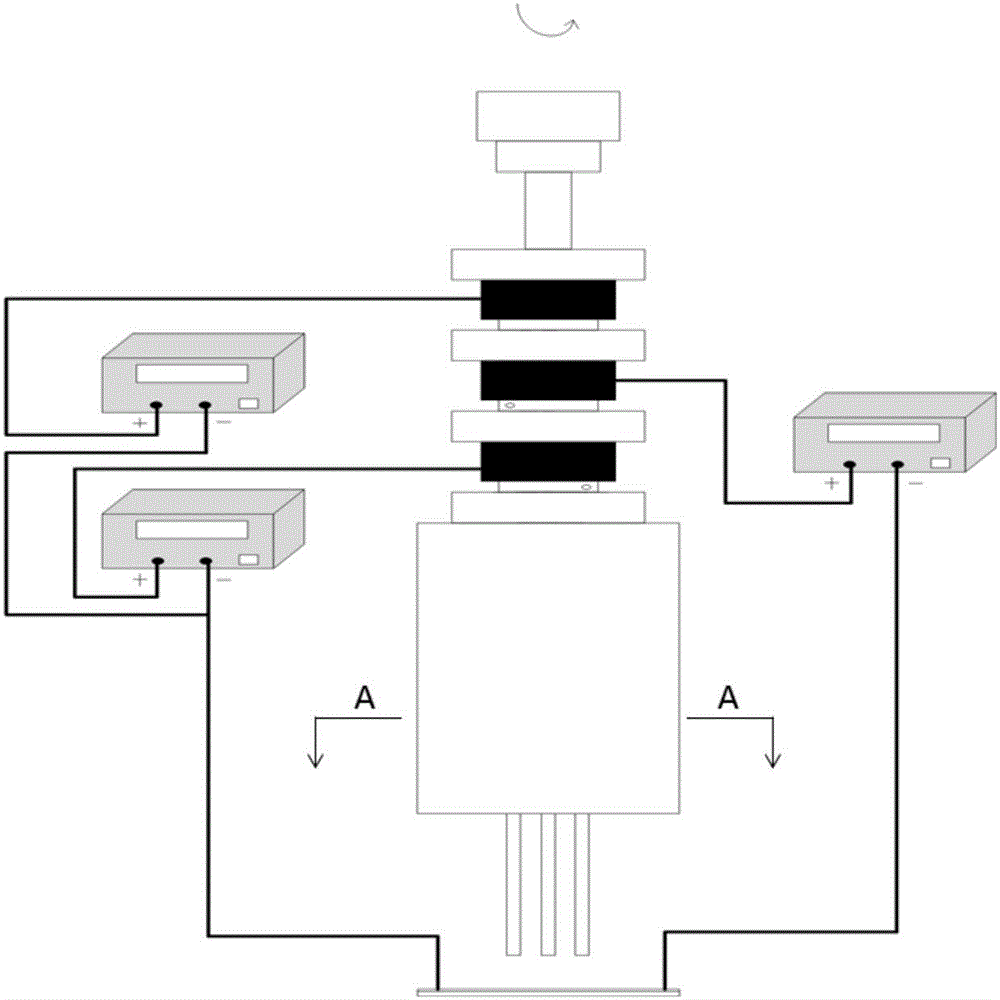

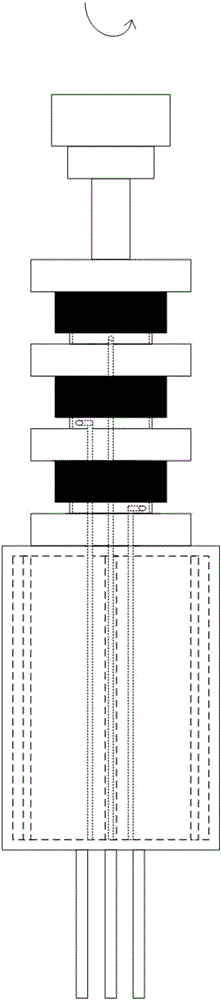

[0047] Figure 2-Figure 6 It is a three-component composite helical micro-nano fiber spinning device. Dissolve PCL particles in dichloromethane and stir magnetically at room temperature until PCL is completely dissolved in dichloromethane to obtain an electrospinning solution with a mass fraction of 8%; similarly , PLGA was dissolved in dichloromethane to obtain an electrospinning solution with a mass fraction of 10%. Similarly, PVA was dissolved in pure water to obtain an electrospinning solution with a mass fraction of 3%. Close the liquid outlet of the stainless steel nozzle 7, and inject PCL solution, PLGA and PVA solution into the three liquid storage chambers respectively. Fix the upper end of the insulating liquid storage chamber 1 to the output end of the motor 3, control the motor speed to 3k~15kRPM, set the voltage of the three ring brushes to 16kV for PCL solution connection, 12kV for PLGA solution connection, 18kV for PVA solution connection, stainless steel nozzl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com