Methane engine ignition control method

An ignition control and engine technology, applied in the direction of engine control, electrical automatic control, electric engine control automatic control, etc., can solve the problems of high gas consumption, user inconvenience, poor emission performance, etc., and achieve significant comprehensive benefits, wide distribution, and construction costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below:

[0018] The present invention comprises the following steps:

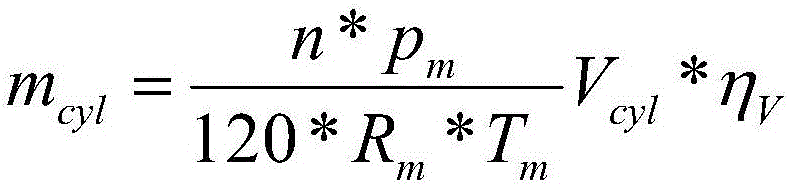

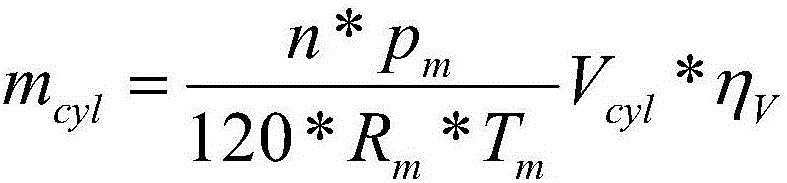

[0019] (1) Gas injection control: To accurately provide the quality of biogas to the engine, it is determined by the speed-density method, and the mathematical relationship is as follows:

[0020]

[0021] In the above formula: m cyl The air mass flow rate entering the cylinder per working cycle; η V is the charging efficiency of the cylinder; V cyl is the cylinder volume (m 3 ); n is the engine speed (r / min); p m is the intake pipe pressure (kPa); Tm is the intake pipe temperature (K);

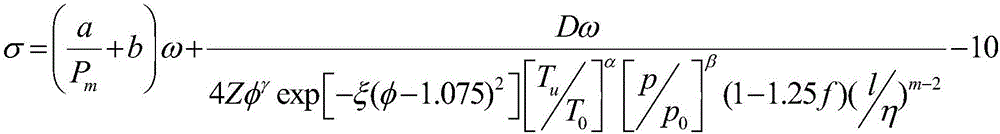

[0022] (2) Ignition control: The ignition advance angle is an important parameter to determine the performance of the engine. In order to accurately provide the ignition time in the operation of the biogas engine, the internal combustion engine combustion theory, combined with related theories, can obtain the ignition advance angle. The mathematical relationshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com