Multi-angle three-dimensional contour measuring system and measuring method

A three-dimensional profile and measurement system technology, applied in the field of optical inspection, can solve the problems of time-consuming and laborious, and achieve the effect of high measurement accuracy, fast speed and large field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

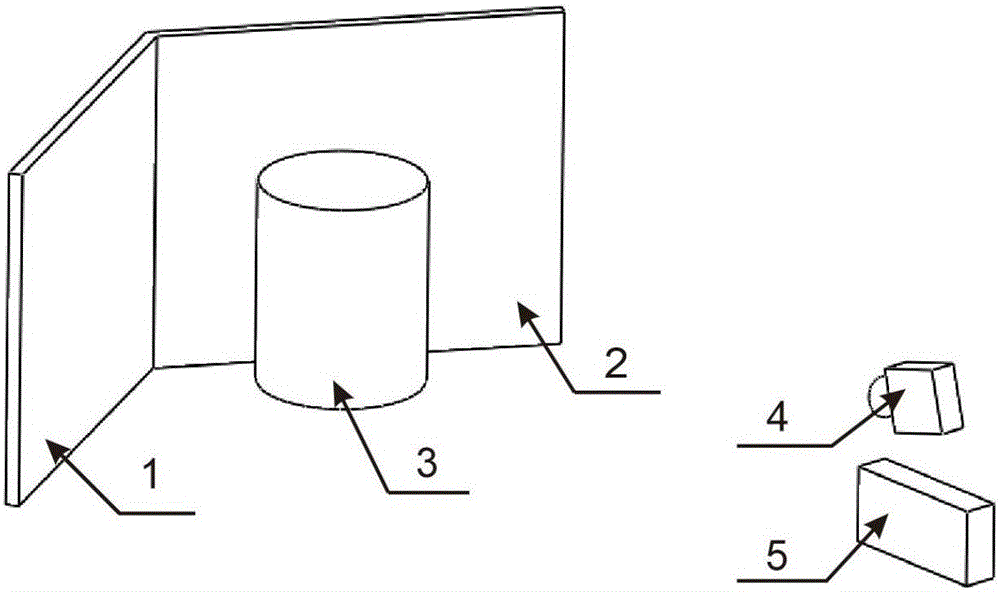

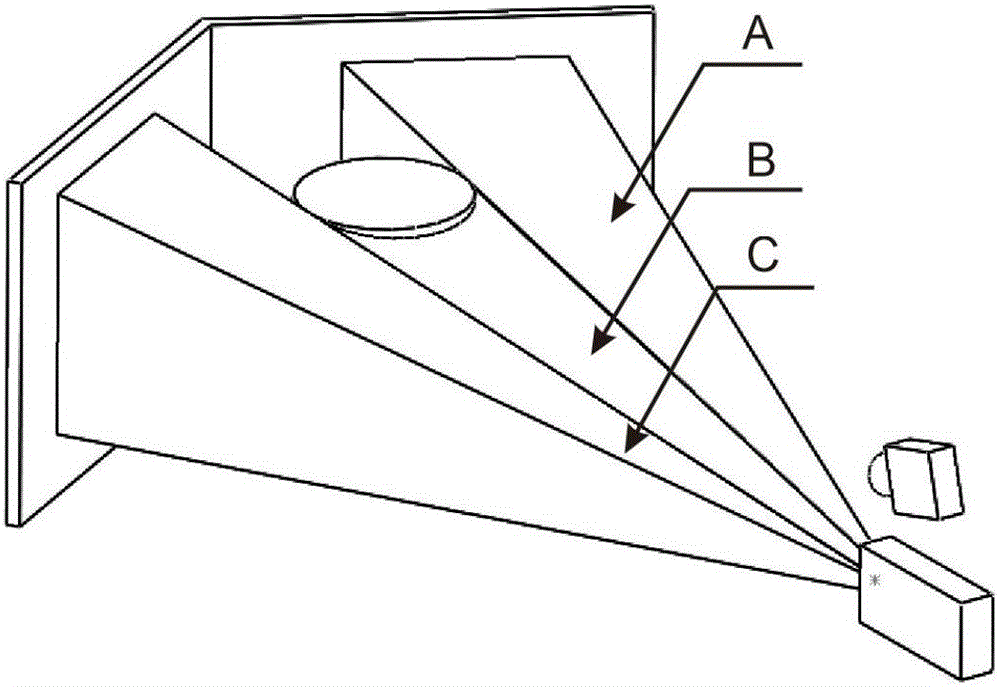

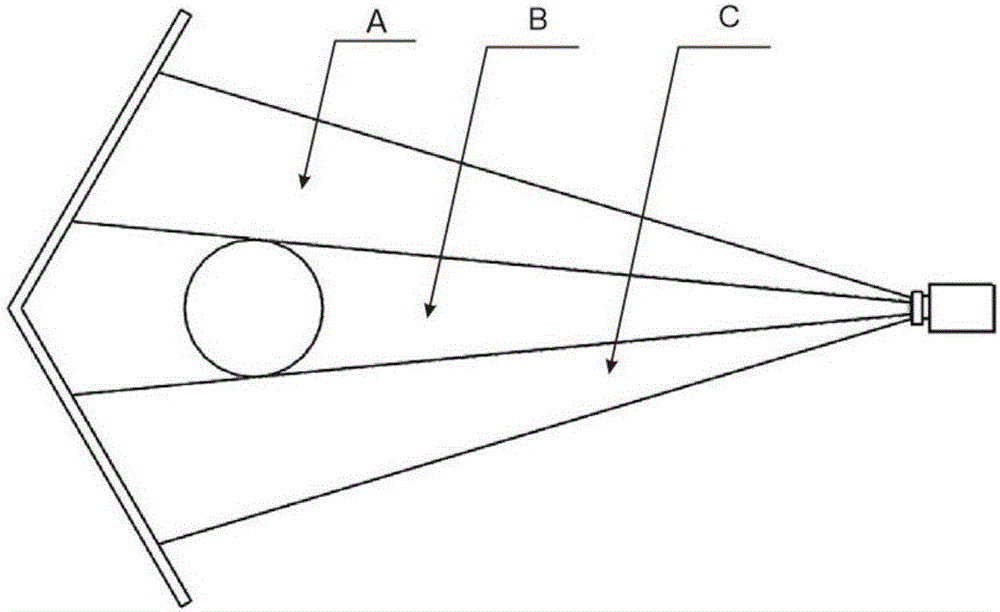

[0040] see Figure 1-12, a multi-angle three-dimensional measurement system, the system consists of one or more cameras, a laser MEMS (Micro-electromechanical Systems) projection device and two mirrors, the laser MEMS projection device is placed directly above the measured object, and the mirrors are symmetrical Placed on both sides of the measured object and at a certain angle with the measured object, so that the left and right sides of the measured object are imaged in the mirror, the camera can collect the left and right sides of the measured object through the left and right mirrors, and also The front surface of the measured object can be collected, that is, the 360-degree contour features of the measured object can be collected. The projection field of view of the laser MEMS projection device is divided into three areas: A, B, and C. Area A is the field of view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com