Method for detecting sulfur trioxide in coal ash

A technology of sulfur trioxide and coal ash, applied in the preparation of test samples, measuring devices, sampling, etc., can solve problems such as low results, achieve high accuracy and precision, improve accuracy and precision, and shorten The effect of testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

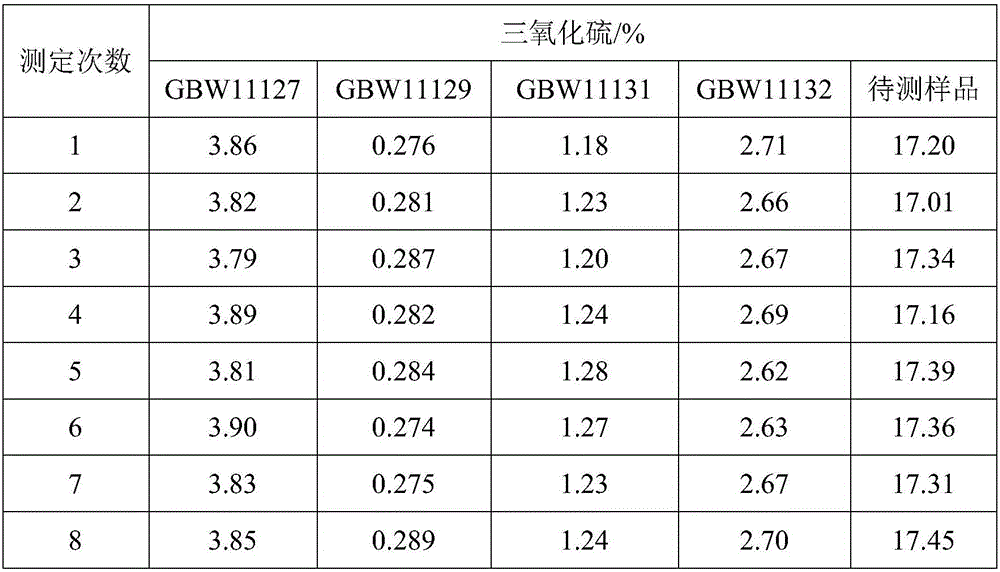

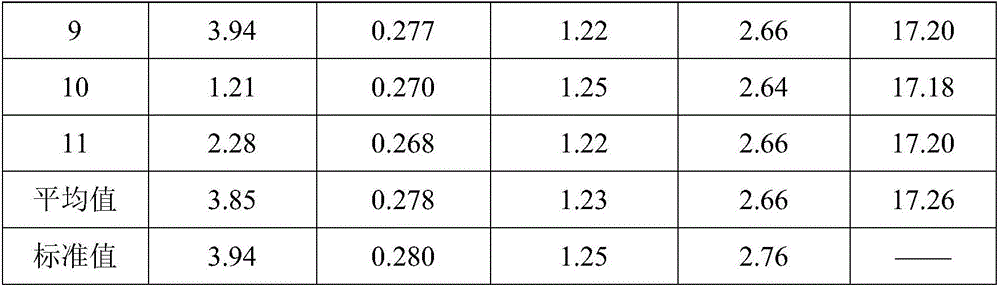

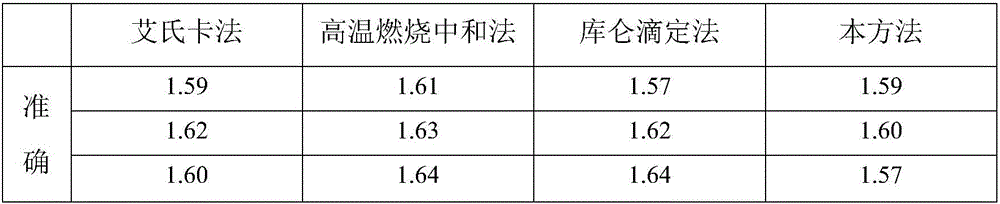

[0048] Example 1

[0049] A method for determining sulfur trioxide in coal ash includes the following steps:

[0050] 1. Treatment of coal ash samples and standard products:

[0051] Step (1): Weigh a certain amount of general analysis coal ash sample in the ash dish, and send the ash dish into the muffle furnace at a temperature not exceeding 100°C. Under the condition of natural ventilation and a 15mm gap in the furnace door, take 30 minutes Slowly rise to 500℃, keep at this temperature for 30min, raise to (815±10)℃, burn at this temperature for 2h.

[0052] Step (2): Take out and cool, use an agate mortar to grind the coal ash sample to a particle size of 0.075mm, then place it in a ash dish and burn it at (815±10)°C for 30 minutes until the quality is constant. Put into the ash sample bag.

[0053] Step (3): Take out an appropriate amount of anhydrous calcium sulfate, burn it at 500°C for 2h, and put it in a desiccator to cool to room temperature.

[0054] Step (4): Take the prepar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap