Manipulator self provided with wafer edge-searching sensor

A sensor and manipulator technology, applied in the field of manipulators, can solve the problems of increased chip manufacturing costs, secondary contamination of wafers, and increased EFEM costs, and achieve the effect of continuous working, avoiding scratches and damage, and reducing secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

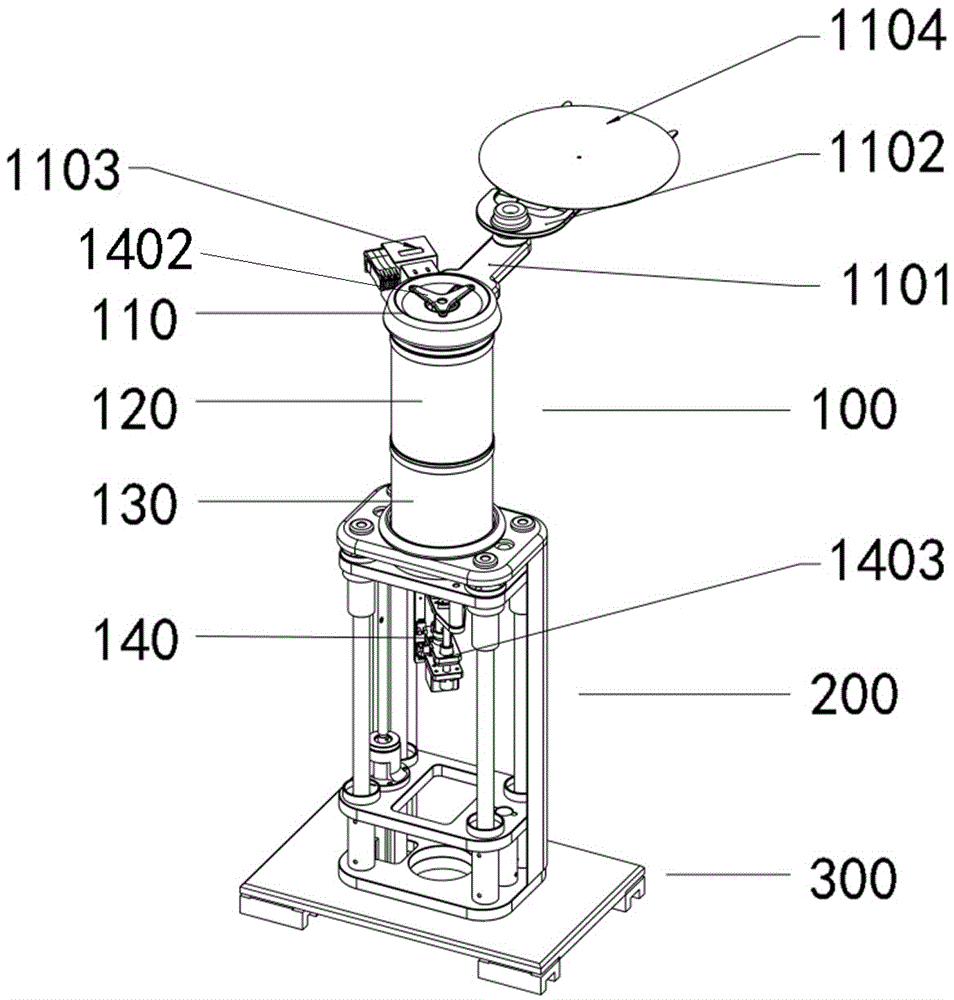

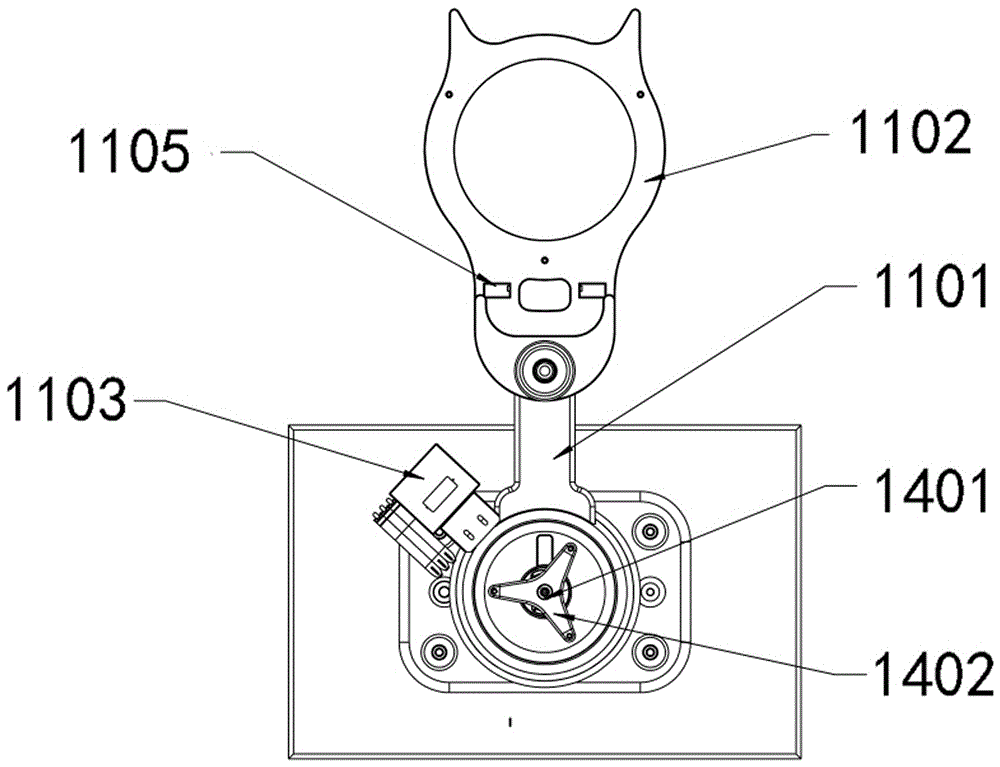

[0044] Such as figure 1 , 9 As shown, a manipulator equipped with a wafer edge detection sensor includes a main arm 100 , a mandrel assembly 140 , a manipulator lifting mechanism 200 and a slide 300 . The main arm 100 is located at the top and adopts a first hollow structure. Its lower end is fixedly connected to the manipulator lifting mechanism 200. The manipulator lifting mechanism 200 is fixedly connected to the sliding seat 300. The mandrel assembly 140 runs through the first hollow structure and is connected with the manipulator. The lifting mechanism 200 is connected.

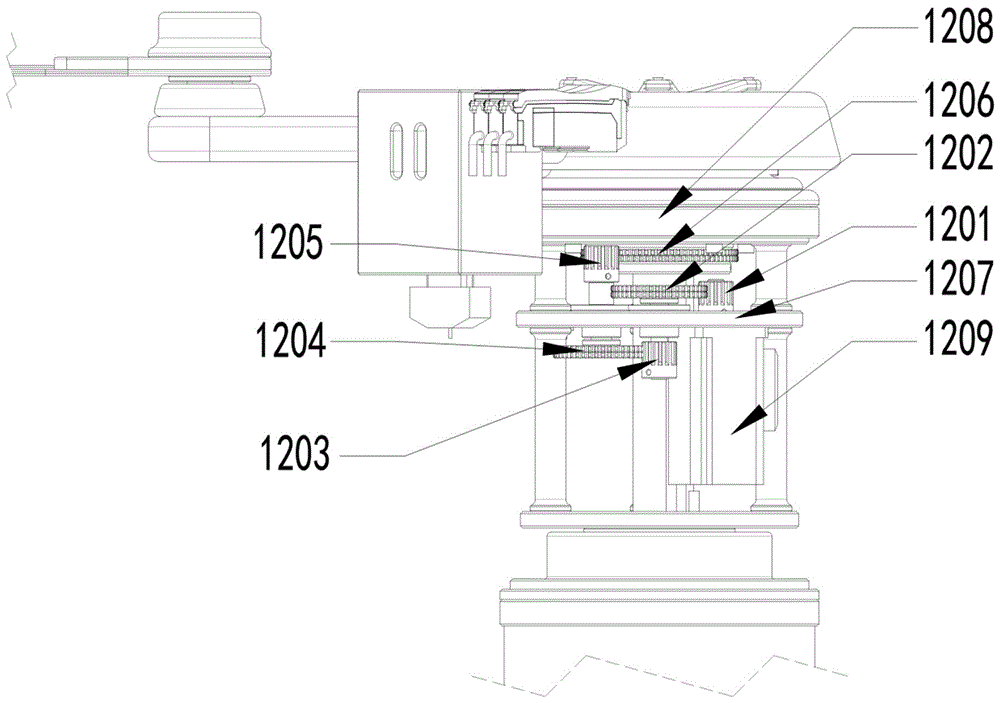

[0045] Such as figure 1 As shown, the main arm 100 includes a first main arm assembly 110 , a second main arm assembly 120 and a third main arm assembly 130 . The first main arm assembly 110 is located at the top, the bottom end of the first main arm assembly 110 is connected to the top end of the second main arm assembly 120, the bottom end of the second main arm assembly 120 is connected to the top ...

Embodiment 2

[0060] A manipulator with a built-in wafer edge detection sensor is similar to Embodiment 1, the difference is that it also includes a counterweight spring 206 and a lift limit mechanism.

[0061] Such as Figure 12 , as shown in 13, the lift limit mechanism includes a main arm limit piece 402 and a limit post 401. The main arm limiting piece 402 is disposed at the lower end of the main arm 100 and can rotate with the main arm 100 . The limit column 401 is located on the manipulator lifting mechanism 200 . Limit post limit piece 403 is arranged on limit post 401, and limit post limit piece 403 can be a plurality of annular pieces that are arranged at intervals, and the distance between adjacent limit post limit pieces 403 is the same as that in the cassette. Neighboring wafers are equally spaced.

[0062] Such as Figure 14 , as shown in 15, all the limiting posts 403 on the limiting post 401 and the limiting posts 401 together constitute the first electrode 4031, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com