Intelligent shoe cabinet

A shoe cabinet and intelligent technology, applied in wardrobes, cabinets, household appliances, etc., can solve the problems of shoe discoloration, aging, shortening the life of shoes, etc., to avoid cross-contamination and increase the effect of beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to understand the present invention more clearly, the present invention will now be described in detail in combination with specific embodiments and accompanying drawings.

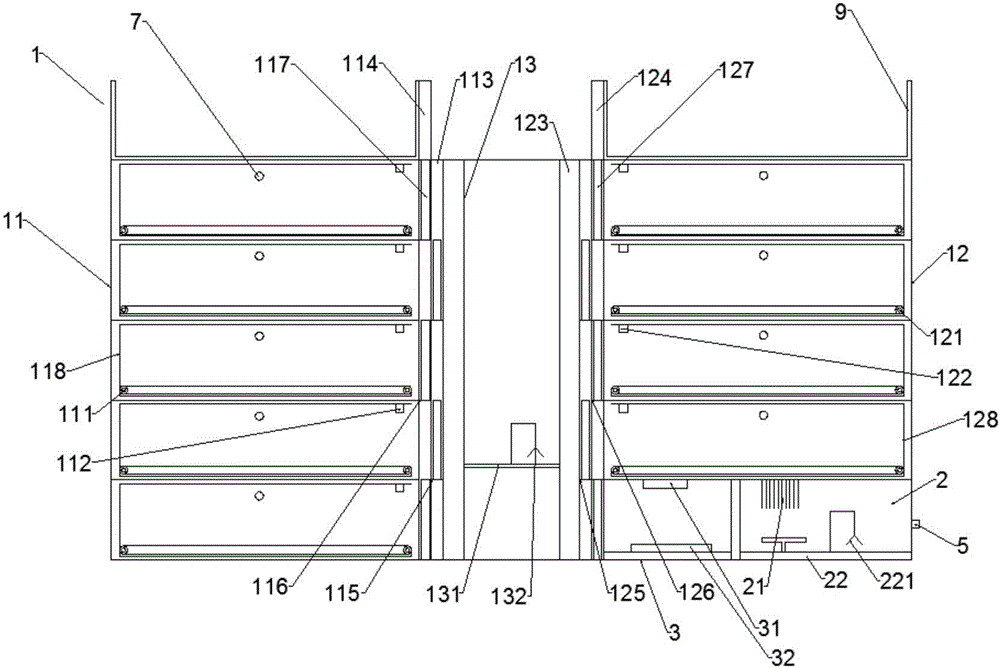

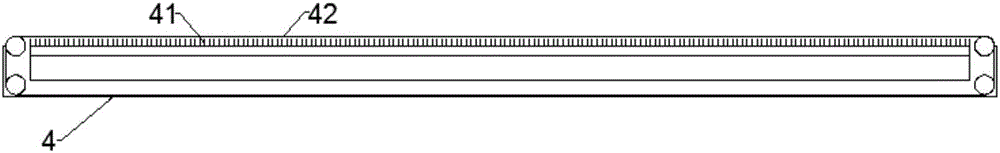

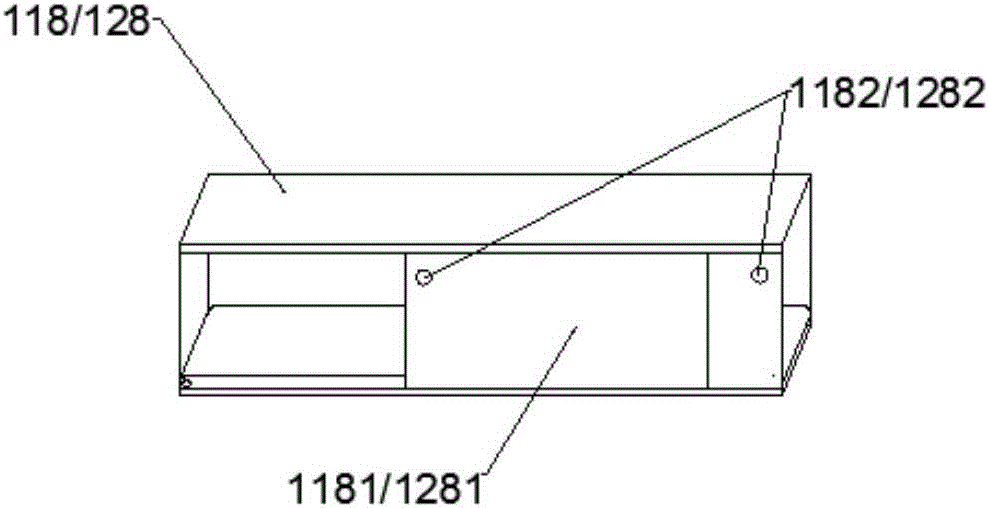

[0021] Such as figure 1 As shown, the smart shoe cabinet of the present invention includes a shoe cabinet body 1 and a shoe polishing device 21 , a sterilizing device 31 and a deodorizing device 32 located in the shoe cabinet body 1 . Wherein, the shoe cabinet body 1 is mainly divided into two left and right shoe storages, one of which is a common storage 11 and the other is a clean storage 12 . The common warehouse 11 and the clean warehouse 12 are divided into multiple layers by horizontal partitions, and conveyor belts (111, 121) are arranged at the bottom of each common warehouse 11 or each clean warehouse 12. Between the ordinary warehouse 11 and the clean warehouse 12, an automatic elevator 13 is arranged to be stored in layers. another side. Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com