Solid cylinder gluing method and product thereof

A cylindrical and solid technology, used in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of limited length and small cylinder diameter, reduce cracking and deformation, improve yield, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The following is an example of processing a cylinder with a diameter of 500mm and a length of 10m:

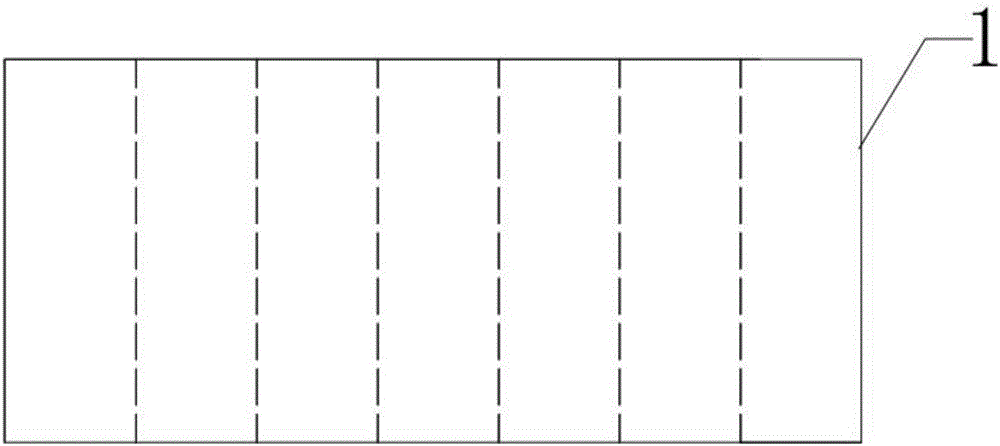

[0031] 1) Select laminates with a thickness of 42mm, a width of 130mm, and a length of 10m, coat the laminates with adhesive, bond the 7 laminates, pressurize and cure them, and put them on display to obtain glulam 1 with a size of 294*130mm. Such as figure 1 shown;

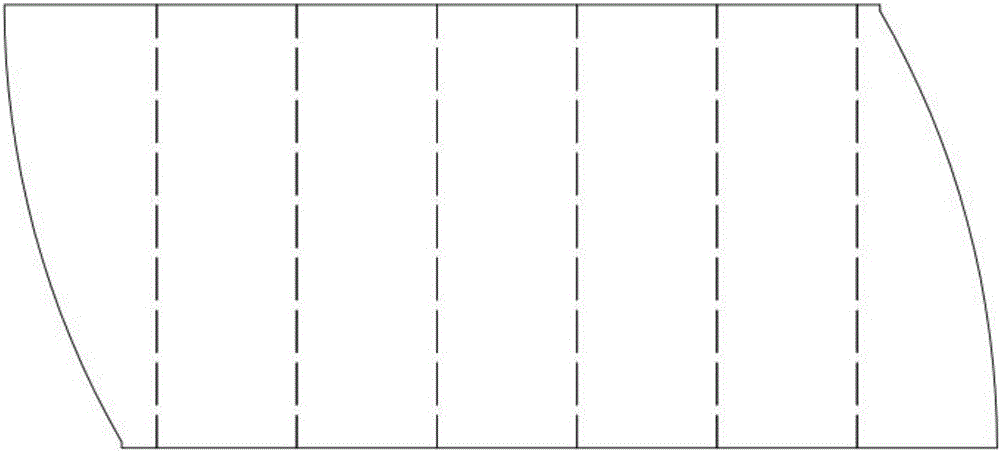

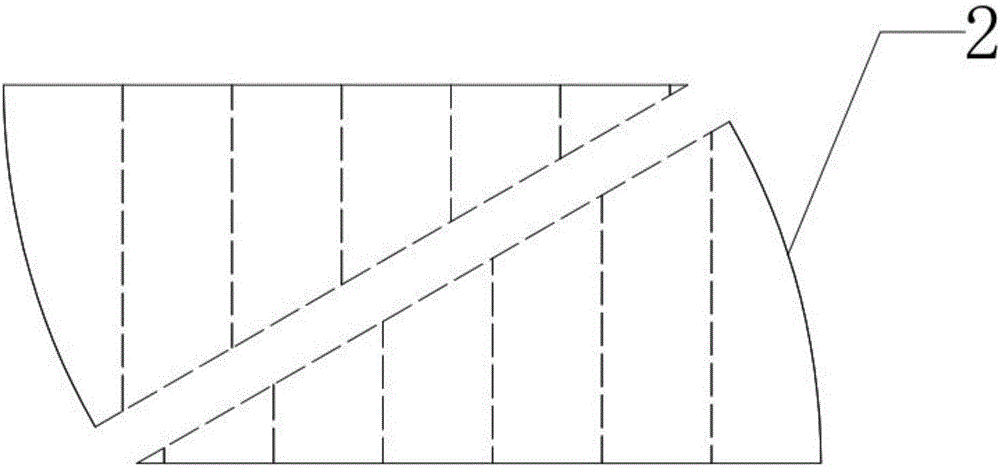

[0032] 2) Carry out planing and milling processing of integrated panels, such as figure 2 shown. Then it is divided obliquely, and one is divided into two to obtain two fan-shaped unit bodies 2 whose bottoms are arc-shaped, and the side length of the fan-shaped unit body is 250mm, such as image 3 shown;

[0033] 3) Apply glue to the two isosceles sides of the fan-shaped unit body obtained in 12 steps 2), and then combine them to make a circle to obtain the required solid cylinder 3, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com