Pore forming substance for reticular porous material and preparation method thereof

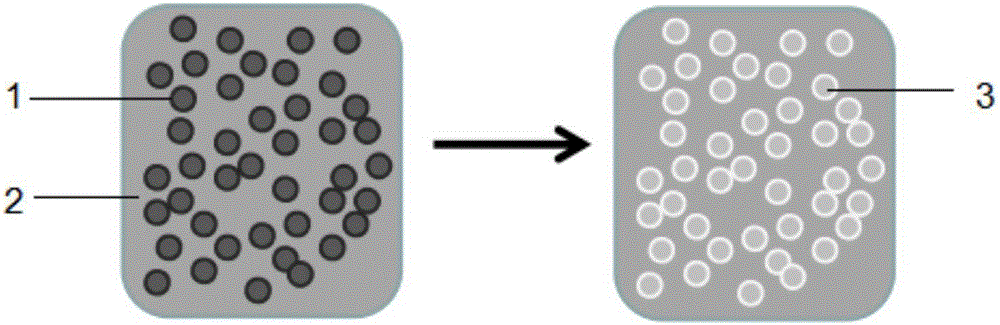

A mesh-like porous and pore-forming agent technology, applied in the field of materials, can solve the problems of easy aggregation of micelles, damage to porous materials, and difficulty in control, and achieve the effects of strong hydrophilicity, increased specificity, and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A pore-forming agent for reticular porous materials, the molecular structural formula of the pore-forming agent is as follows:

[0036]

[0037] where: R 1 , R 2 , R 3 , R 4 It is polyoxyethylene ether or diisooctyl phosphate linked to the parent, and polyoxyethylene ether and diisooctyl phosphate must exist simultaneously in each pore-forming agent molecule.

[0038] A method for preparing a pore-forming agent for reticular porous materials, using sorbitan as the matrix structure, grafting polyoxyethylene ether on some of its hydroxyl groups through reaction, and then adding hydrophobic groups to react with the remaining hydroxyl groups, thereby Obtain the pore-forming agent that is used for preparing mesh porous material, concrete steps are as follows:

[0039] In the first stage, mix sorbitan and polyoxyethylene ether, add 3.0% sodium hydroxide by mass of the mixture as a catalyst, and stir and react in an oil bath at 120°C for 9 hours;

[0040] In the second...

Embodiment 2

[0043] A pore-forming agent for reticular porous materials, the molecular structural formula of the pore-forming agent is as follows:

[0044]

[0045] where: R 1 , R 2 , R 3 , R 4It is polyoxyethylene ether or myristyl alcohol linked to the parent body, and polyoxyethylene ether and myristyl alcohol must exist simultaneously in each pore-forming agent molecule.

[0046] A method for preparing a pore-forming agent for reticular porous materials, using sorbitan as the matrix structure, grafting polyoxyethylene ether on some of its hydroxyl groups through reaction, and then adding hydrophobic groups to react with the remaining hydroxyl groups, thereby Obtain the pore-forming agent that is used for preparing mesh porous material, concrete steps are as follows:

[0047] In the first stage, mix sorbitan and polyoxyethylene ether, add 2.0% of the mass of the mixture of sodium hydroxide as a catalyst, and stir and react in an oil bath at 140°C for 9.5 hours;

[0048] In the s...

Embodiment 3

[0051] A pore-forming agent for reticular porous materials, the molecular structural formula of the pore-forming agent is as follows:

[0052]

[0053] where: R 1 , R 2 , R 3 , R 4 It is polyoxyethylene ether or decyl alcohol linked to the parent, and polyoxyethylene ether and decyl alcohol must exist simultaneously in each pore-forming agent molecule.

[0054] A method for preparing a pore-forming agent for reticular porous materials, using sorbitan as the matrix structure, grafting polyoxyethylene ether on some of its hydroxyl groups through reaction, and then adding hydrophobic groups to react with the remaining hydroxyl groups, thereby Obtain the pore-forming agent that is used for preparing mesh porous material, concrete steps are as follows:

[0055] In the first stage, mix sorbitan and polyoxyethylene ether, add 2.5% sodium hydroxide by mass of the mixture as a catalyst, and stir and react in an oil bath at 140°C for 9 hours;

[0056] In the second stage, decyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com