High-steady-state, high-effect, and large-volume fermenting tank

A high-efficiency, large-capacity technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical equipment, etc., can solve the problem of tank weld cracking, time-consuming and laborious, and low production efficiency and other problems, to achieve energy-saving, high-efficiency production, good dissolved oxygen effect, and no replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

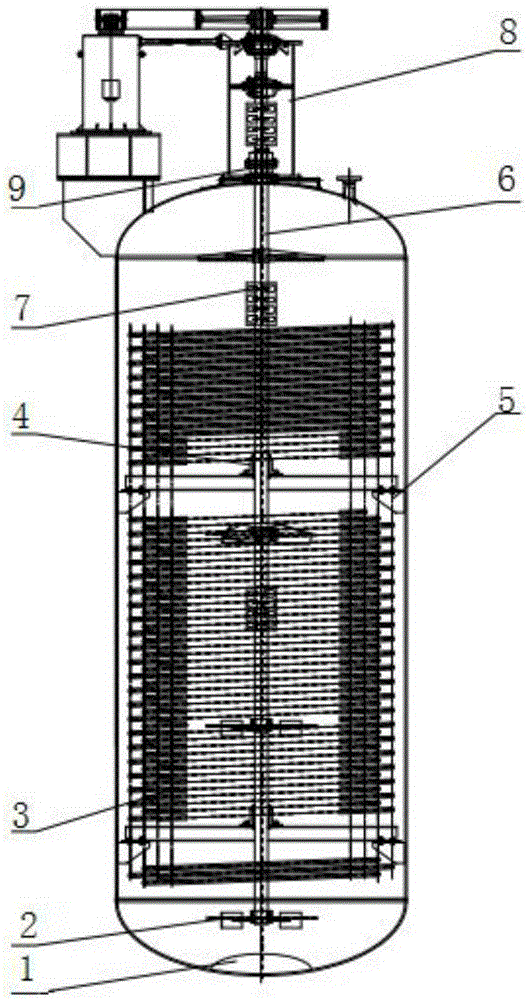

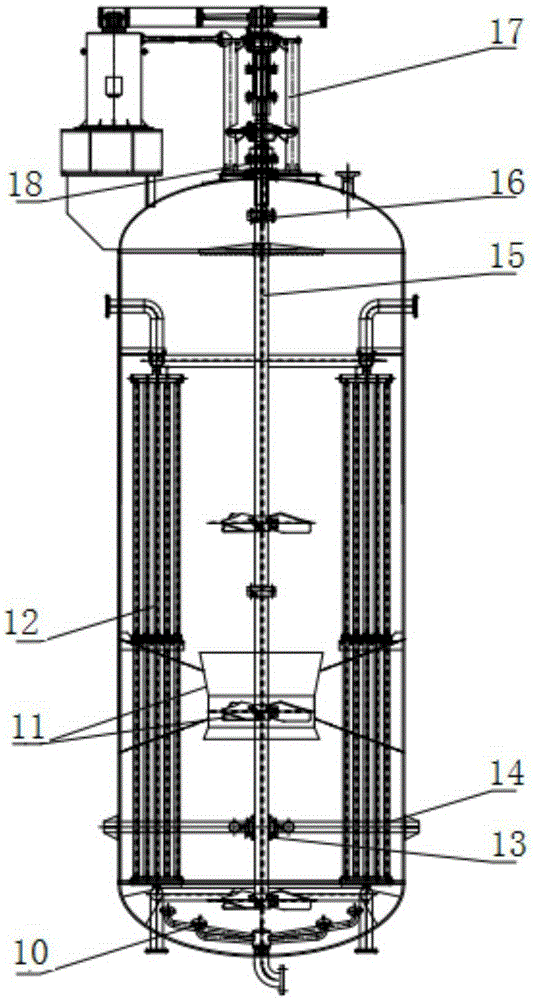

[0034] like figure 2As shown, the high-steady-state, high-efficiency and large-volume fermentation tank includes two parts outside the tank and inside the tank. Except for the tank body, the motor base, and the pulley outside the tank, the frame of the stirring transmission device adopts a four-column frame 17. The overall stability is enhanced, and the space in the column becomes larger, which is convenient for the installation and maintenance of the coupling and mechanical seal. The original cylindrical frame is very inconvenient for the installation and maintenance of couplings and mechanical seals due to the small internal space;

[0035] The mechanical seal at the top of the tank at the center of the upper head adopts the 204J static mechanical seal 18 in the application number 201520013895.2. During the operation, due to the good floating of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com