Particle damper with multi-mechanism energy dissipation function

A particle damper and damper technology, which is used in building components, earthquake resistance, construction, etc., can solve problems such as limited energy consumption capacity, and achieve the effects of increasing exercise capacity, reducing impact force and noise, and enriching energy consumption mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

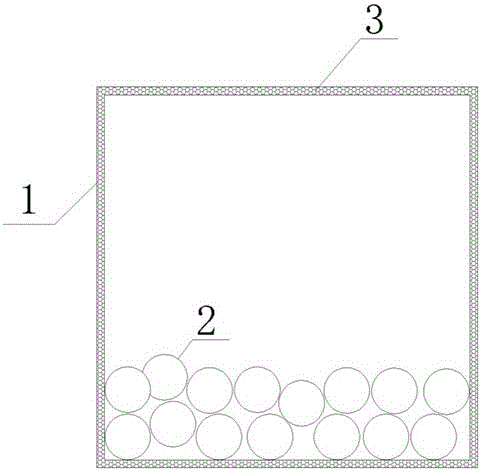

[0016] Embodiment 1: as figure 1 As shown, it is an embodiment of a chain particle collision damper of the present invention, which mainly includes a damper cavity unit 1 and a particle group 2 .

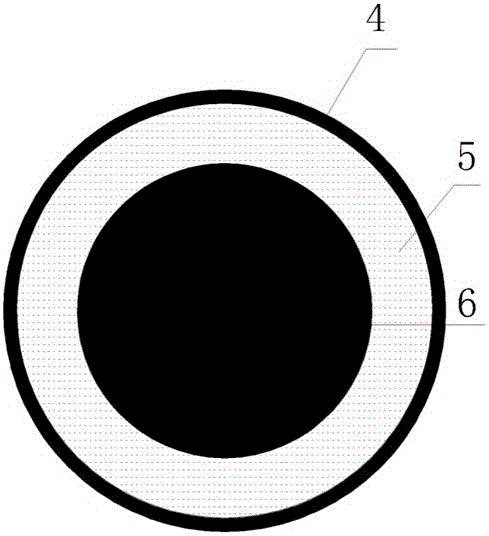

[0017] The damper cavity unit 1 is a cuboid cavity welded by 5mm-10mm thick steel plates, and is fixed to the structure in a certain way. Each particle constituting the particle group 2 is composed of a particle shell 4 , a viscous liquid 5 and a metal ball 6 . The spherical particle shell 4 is a steel metal shell, the inner spherical metal ball 6 is a steel ball, and the viscous liquid 5 filling the shell is any one of oil, glue or silica gel; the diameter of the spherical particle is 60mm, and the particle shell 4 The wall thickness is 3-5mm, and the diameter of the inner metal ball 6 is 30-40mm; the volume of the particle group 2 is 5%-20% of the volume of the damper cavity unit 1 .

[0018] A buffer material 3 (such as 5mm thick rubber, foam plastic or knitted cotton) is paste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com