Concrete freeze-thaw expansion strain sensor

A technology of expansion strain and concrete, which is applied in the field of sensors, can solve the problems of not being able to reflect the freeze-thaw damage of concrete in active service, and cannot achieve real-time monitoring, and achieve the effects of eliminating errors, good durability, and flexible collection intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

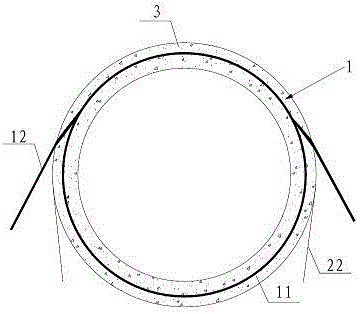

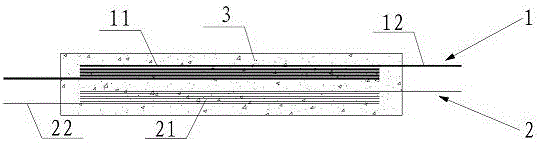

[0018] Such as figure 1 with figure 2 The concrete freeze-thaw expansion strain sensor mainly includes a temperature compensation optical fiber 1 , a single-mode bending-resistant bare optical fiber 2 and a cement mortar ring body 3 .

[0019] Wherein, the cement mortar ring body 3 is a cement mortar column with a hollow cavity inside, and the hollow cavity is concentric with the cement mortar column so that its end surface or a section parallel to the end surface has a ring structure. The temperature compensating optical fiber 1 includes a temperature compensating optical fiber coil 11 and a temperature compensating guiding optical fiber 12, the temperature compensating optical fiber coil 11 is arranged in the cement mortar ring body 3; and there are two temperature compensating guiding optical fibers 12, each temperature compensating guiding op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com