Determination method of aero-engine installation center surface

A technology of aero-engine, determination method, applied in the direction of measuring device, using optical device, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

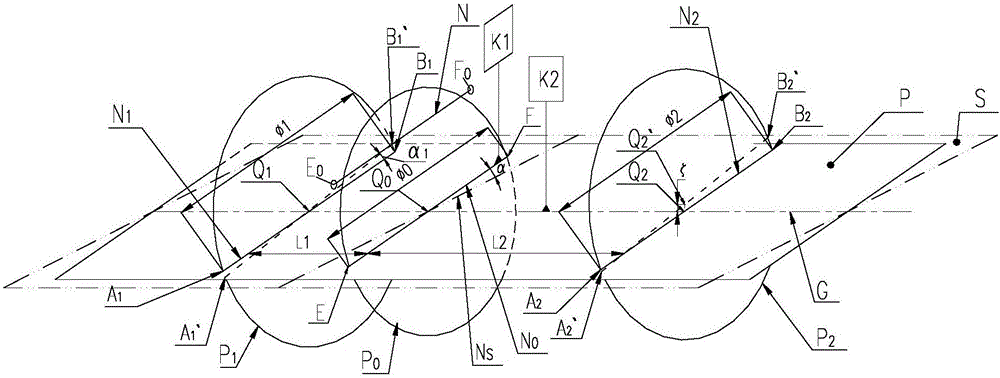

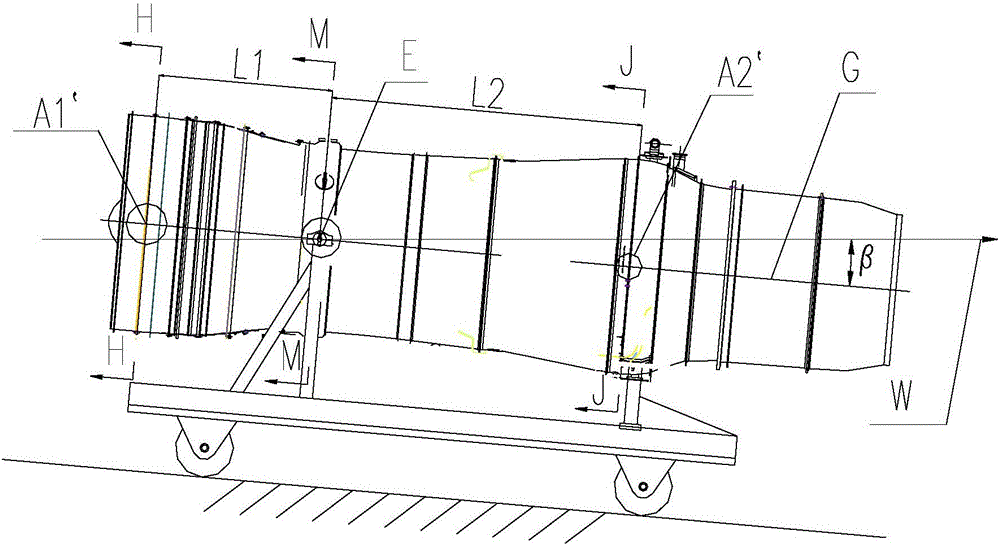

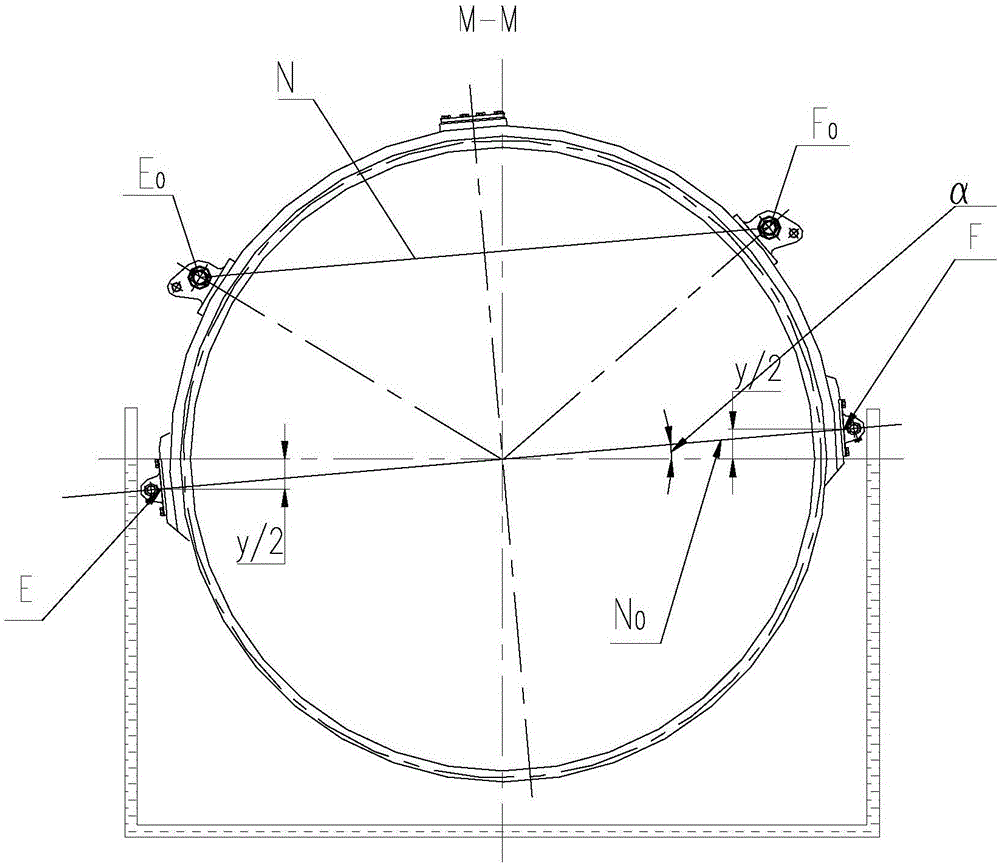

[0054] The engine of this embodiment is a turbofan engine with dual channels, and the outer circle P of the measuring point before the engine is 1 It is a single-channel casing, and the outer circle of the rear measurement point P 2 It is a double-ducted receiver, and its center Q 2 May deviate from center line G, assuming deviation ( figure 1 , Figure 5 shown along the vertical direction). According to the installation technical requirements of an aircraft, the following measuring instruments and equipment were selected to calibrate the measuring points of the center plane of an aero-engine.

[0055] Measuring instruments and equipment used:

[0056] 1) U-shaped tube (material: transparent PVC transparent plastic tube, tube size: outer diameter 4mm, tube wall thickness 1mm, length 3m), filled with tap water;

[0057] 2) EK-155AP laser line projector;

[0058] 3) The computer prints a transparent tape with a ratio of 1:1 (attached to the U-shaped tube to measure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com