Tracer-gas-volume-fraction-based integral measurement and calculation method for air leakage of working face behind support

A technology of tracer gas and volume fraction, applied in the direction of liquid tightness measurement using liquid/vacuum degree, measuring device, and detecting the appearance of fluid at the leak point, etc., which can solve the problem of rough results, less application, and heavy testing workload and other problems, to achieve the effect of high accuracy, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

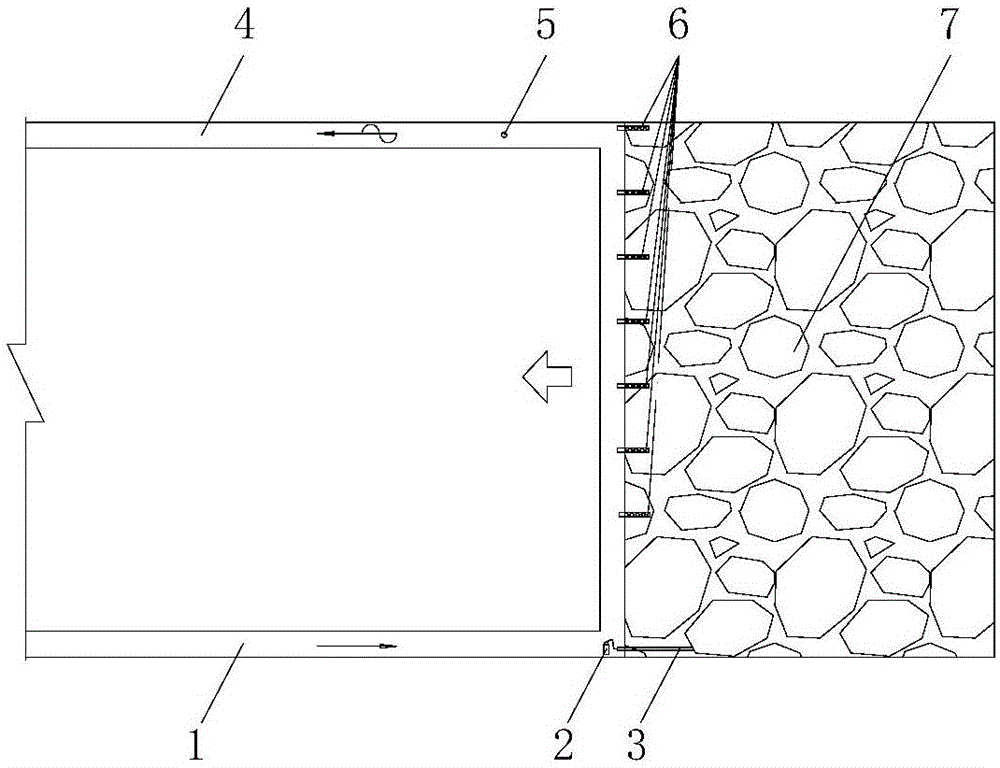

[0008] Such as figure 1 As shown, a tracer gas volume fraction integration method for calculating the air leakage behind the working face frame is carried out as follows:

[0009] Arrange tracer gas release steel cylinders on the air inlet side of the lower corner of the working face, and release the tracer gas in a constant amount to a certain depth in the goaf near the lower corner of the working face by using pressure reducing valves, flow control devices and release pipes to avoid Effect of wind flow pressure on tracer gas.

[0010] At intervals of a certain number of supports along the length of the working face, the gas measuring tube is used to extend into the support from the gap between the supports, extract the gas in the goaf, inject it into the gas sampling bag, bring it to the ground, and use the gas chromatograph to analyze the gas. trace gas volume fraction.

[0011] Take the surface length direction as the abscissa and the tracer gas volume fraction as the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com