Wide-range pesticide spraying machine

A spraying machine and a wide-width technology, which is applied to the device for catching or killing insects, application, animal husbandry, etc., can solve the problems of high labor intensity, heavy load on the operator, and insufficient power, so as to reduce labor intensity and work The effect of broadening the surface and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

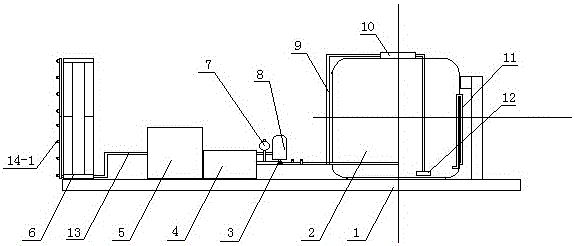

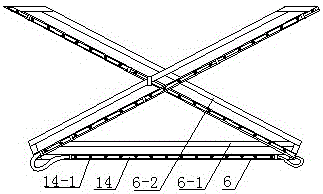

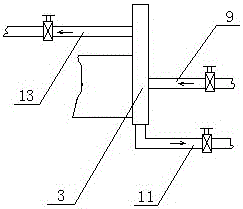

[0029] like figure 1 , figure 2 , image 3 As shown, the wide-width pesticide spraying machine of the present invention includes a frame 1 and a liquid storage tank 2 positioned on the frame, a hydraulic pump 4, a hydraulic pump drive mechanism 5 and a spraying mechanism, and the liquid storage tank 2 is communicated with a feeder. The liquid pipe 9 and the stirring liquid transmission pipe 11, the liquid inlet and outlet of the hydraulic pump 4 are provided with a manifold 3, one side of the manifold 3 is connected with the liquid inlet and outlet of the hydraulic pump 4, the liquid inlet is connected with the liquid supply pipe 9, and the outlet The liquid port communicates with the stirring liquid delivery pipe 11 and the medical solution delivery pipe 13 . The top of the liquid storage tank 2 is provided with a feeding port 10, and the liquid feeding pipe 9 stretches into the bottom of the liquid storage tank 2, and its inlet can be connected to a filter screen 12 to av...

Embodiment 2

[0032] combine image 3 see Figure 4 , the wide-width pesticide spraying machine of the present embodiment, the pesticide spraying machine includes a frame 1 and a liquid storage tank 2 positioned at the frame 1, a hydraulic pump 4, a hydraulic pump drive mechanism 5 and a spraying mechanism, and the liquid storage The tank 2 is connected with a liquid supply pipe 9 and a stirring liquid transmission pipe 11. The inlet and outlet of the hydraulic pump 4 are provided with a manifold 3. One side of the manifold 3 communicates with the inlet and outlet of the hydraulic pump 4. The liquid pipe 9 communicates, and the liquid outlet communicates with the stirring liquid transmission pipe 11 and the medicinal liquid transmission pipe 13 . The top of the liquid storage tank 2 is provided with a feeding port 10, and the liquid feeding pipe 9 stretches into the bottom of the liquid storage tank 2, and its inlet can be connected to a filter screen 12 to avoid the blockage of the liquid...

Embodiment 3

[0035] see image 3 see Figure 5, the wide-width pesticide spraying machine of the present embodiment includes a frame 1 and a liquid storage tank 2 positioned on the frame 1, a hydraulic pump 4, a hydraulic pump drive mechanism 5, and a spraying mechanism, and the liquid storage pipe 2 communicates with a feeder. The liquid pipe 9 and the stirring liquid transmission pipe 11, the liquid inlet and outlet of the hydraulic pump 4 are provided with a manifold 3, one side of the manifold 3 is connected with the liquid inlet and outlet of the hydraulic pump 4, the liquid inlet is connected with the liquid supply pipe 9, and the outlet The liquid port communicates with the stirring liquid delivery pipe 11 and the medical solution delivery pipe 13 . The top of the liquid storage tank 2 is provided with a feeding port 10, and the liquid feeding pipe 9 stretches into the bottom of the liquid storage tank 2, and its inlet can be connected to a filter screen 12 to avoid the blockage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com