Low-titanium vanadium titano-magnetite flotation titanium collecting agent

A vanadium-titanium magnetite and collector technology, applied in flotation, solid separation, etc., can solve the problems of titanium flotation titanium collector MOH collection performance and selectivity are not very good, and achieve flotation cost Low cost, enhanced collection performance, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

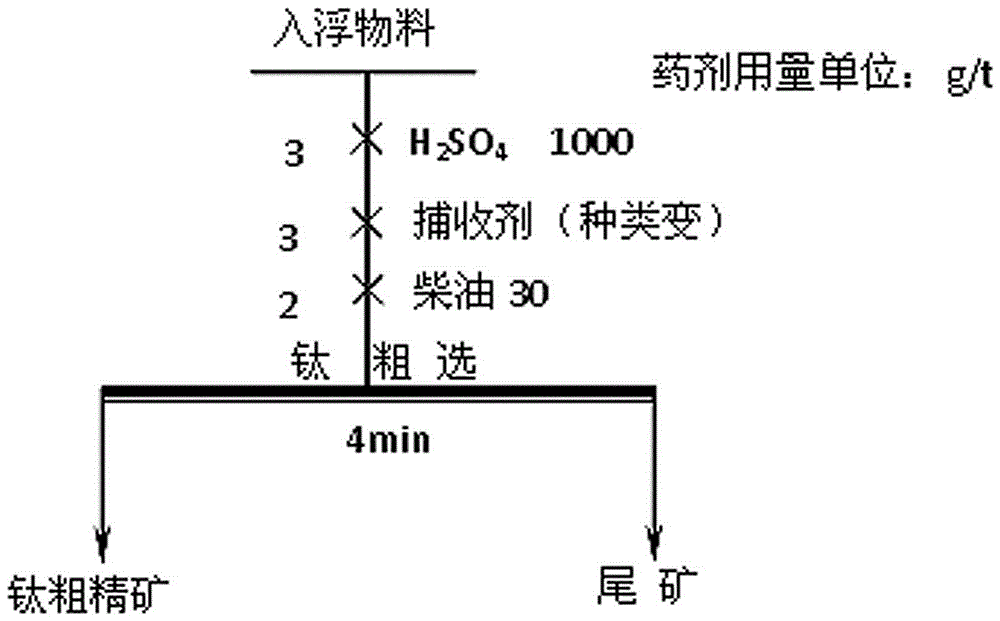

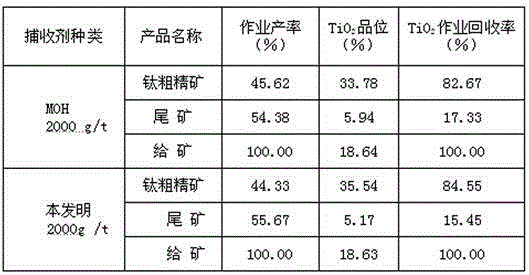

Method used

Image

Examples

Embodiment 1

[0018] The present invention is made up of the following components by weight percentage:

[0019] MOH 75%, butyl phosphate 20%, sulfuric acid 5%, its preparation method is as follows:

[0020] Calculated by 100g weight, first weigh 75g of MOH, add water to dissolve to liquid, then weigh 20g of butyl phosphate and mix, finally add 5g of sulfuric acid, stir evenly and cool to room temperature.

Embodiment 2

[0022] The present invention is made up of the following components by weight percentage:

[0023] MOH 50%, butyl phosphate 40%, sulfuric acid 10%, its preparation method is as embodiment 1.

Embodiment 3

[0025] The present invention is made up of the following components by weight percentage:

[0026] MOH 60%, butyl phosphate 30%, sulfuric acid 10%, its preparation method is as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com