Steel ladle cover lifting device and continuous casting equipment

A lifting device and ladle cover technology, which is applied to casting equipment, metal processing equipment, casting molten material containers, etc., can solve the problems of low factory building, insufficient space for arranging the cover device, and small space, so as to achieve simple structure and low occupancy Effect of small space and simplified drive system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Among them, the use of adjective or adverbial modifiers "horizontal" and "vertical", "upper" and "lower" is only for the convenience of relative reference between multiple groups of terms, and does not describe the meaning of the modified terms. Any specific orientation constraints.

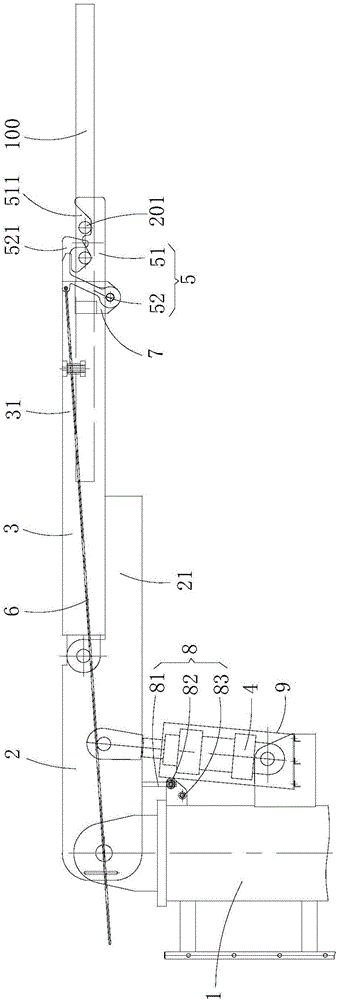

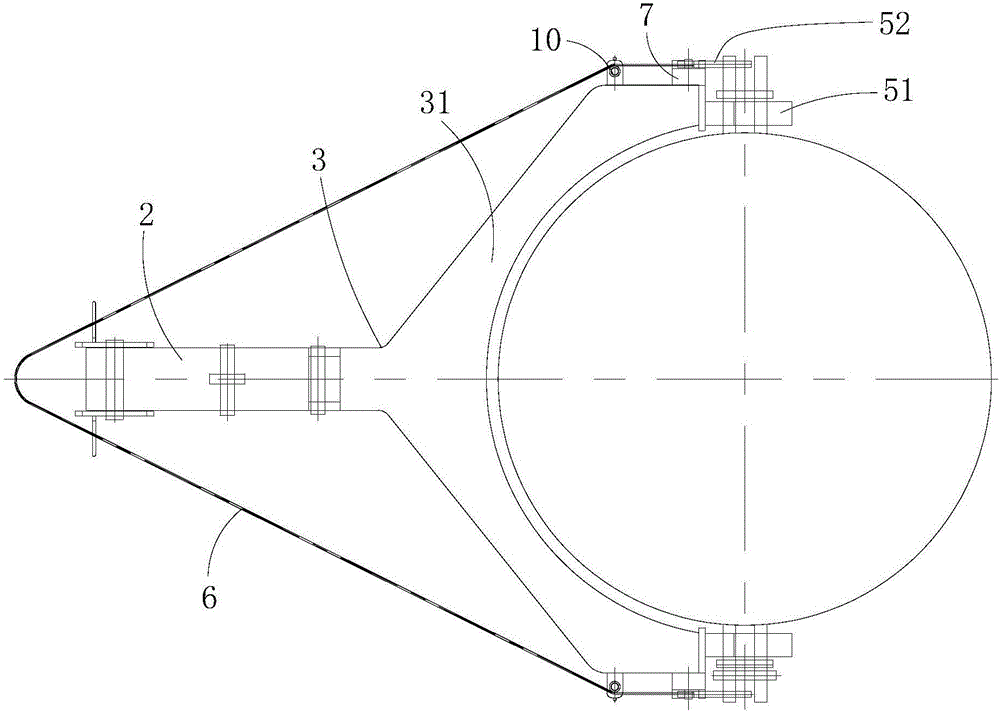

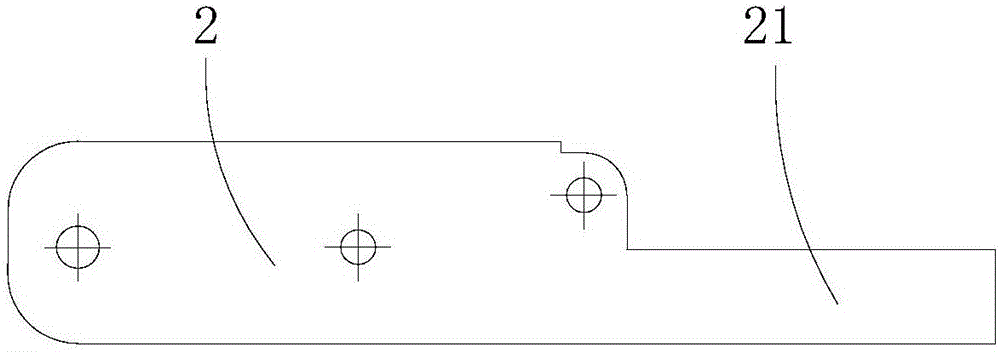

[0053] Such as figure 1 , figure 2 As shown, the present invention provides a ladle cover lifting device, which includes a support 1 (or called a column), a first lifting arm 2, a second lifting arm 3 and a driving device 4, the support 1 is for example vertically arranged, the second One end of a lift arm 2 is rotatably connected to the upper end of the support 1, that is, the first lift arm 2 can swing up and down relative to the support 1 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com