Accurate assembling machine and method for pre-filling type needle tube push rod

An assembly machine and needle tube technology, which is applied in other medical devices, metal processing, infusion sets, etc., can solve the problems of high cost, poor assembly quality of push rods, and low production capacity, so as to reduce cost, increase production efficiency, and simplify equipment compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

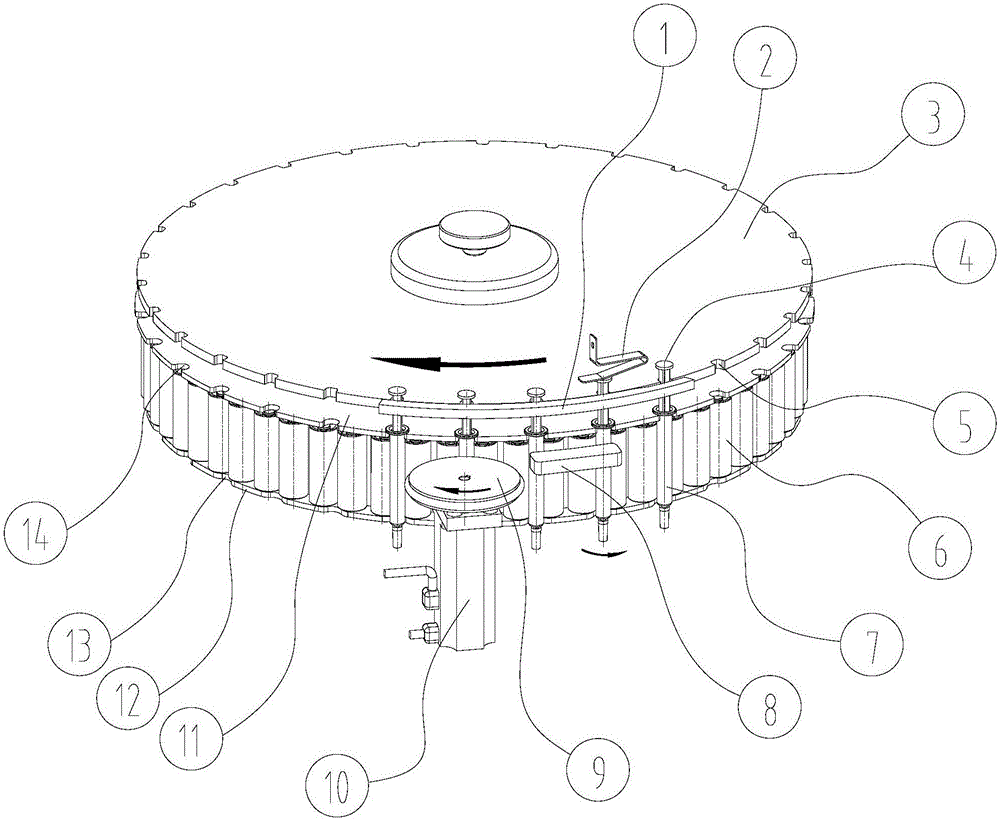

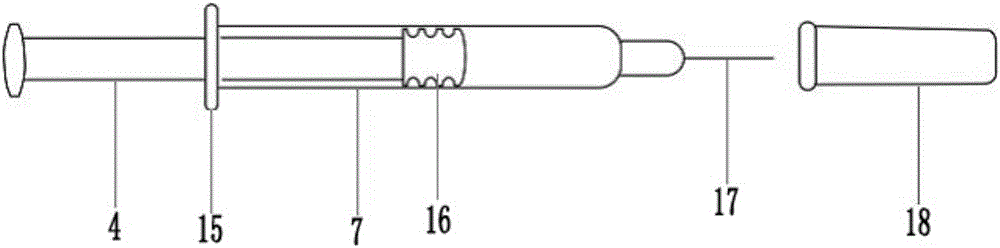

[0033] refer to figure 1 and figure 2 , a pre-filled syringe push rod precision assembly machine provided by the present invention includes a turntable, and the turntable includes an upper circular plate 3, a middle circular plate 11 and a lower circular plate 12 coaxially arranged from top to bottom, and the periphery of the middle circular plate 11 is A plurality of U-shaped needle tube placement openings 14 are evenly provided with outward openings, and the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com