Fine speed regulation device for large-sized mechanical press

An adjustment device and large-scale machinery technology, applied in the field of press parts, can solve the problem that the fine-tuning process of large-tonnage presses cannot be adjusted in place at one time, so as to improve the accuracy of fine-tuning and adjustment efficiency, low speed, and protection from bumps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

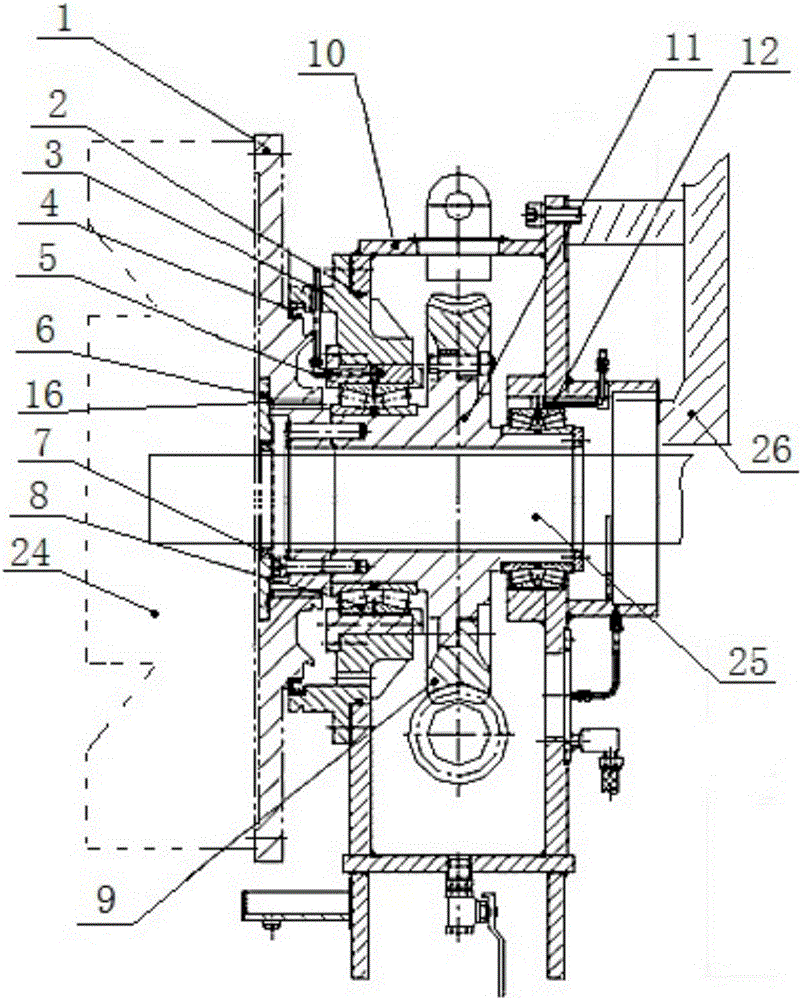

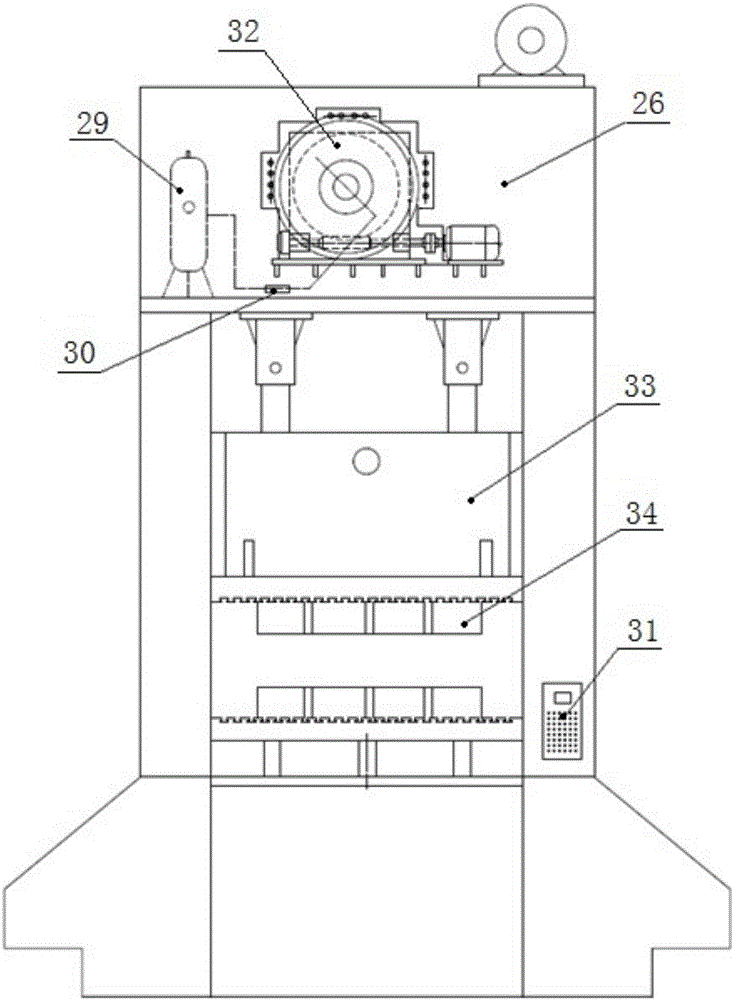

[0018] figure 1 Shown is a schematic front view of the structure of the present invention.

[0019] The present invention includes a worm case 10 , a worm wheel 9 , a worm 18 and a trim brake 15 .

[0020] One side of the worm gear box 10 is fixed on the beam 26, and the other side is connected with the worm gear box support sleeve 3, and the worm gear box 10 and the worm gear box support sleeve 3 form an airtight box.

[0021] A worm wheel 9 is arranged in the airtight box, and the worm wheel 9 is connected with the worm wheel supporting sleeve 11 as a whole, and the two ends of the worm wheel supporting sleeve 11 are respectively provided with a bearing one 8 and a bearing two 12 to realize rotational movement.

[0022] The bearing one 8 is compressed by the bearing sleeve 5, and the bearing sleeve 5 is fixed on the turbine box supporting sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com