Bottle pushing machine for production of glass bottle and provided with pressure buffering device

A buffer device and glass bottle technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as glass bottle damage, inability to pressure buffer, affect production efficiency and production quality, and improve production efficiency and product quality. Quality, Avoid Damaged Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific examples. It will, however, be evident that various changes and modifications can be made to the present invention without departing from the broader spirit and scope of the invention as defined in the appended claims. Therefore, the following examples have an illustrative rather than a limiting meaning.

[0028] Example:

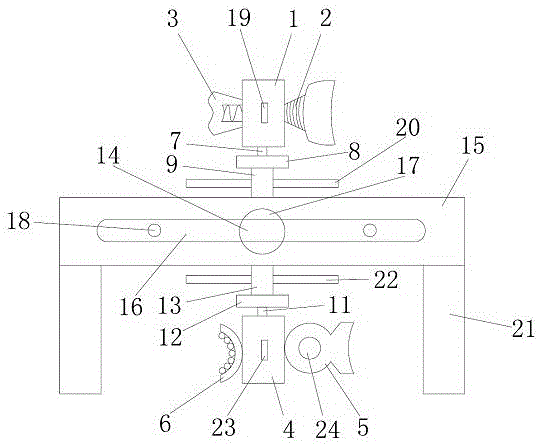

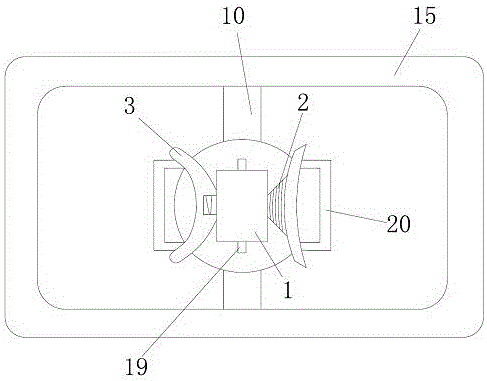

[0029] A bottle pusher for glass bottle production with a pressure buffer device, such as figure 1 and figure 2 As shown, it includes a bottle pushing device. The bottle pushing device includes a groove plate for pushing the bottle. The bottle pushing device is provided with a pressure buffer device. And the air bag suction cup 5 and the flexible ball push plate 6 respectively arranged on both sides of the lower bracket 4;

[0030] The side wall of the corrugated suction cup 2 is provided with a telescopic corrugat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com