Flow guide hydrolysis pot system capable of lifting center flow guide cylinder

A technology of diversion cylinder and hydrolysis tank, which is applied in the field of new integrated adjustment sedimentation tank, which can solve the problems of easy blockage of water distribution branch pipes, many pipes, small pipe diameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

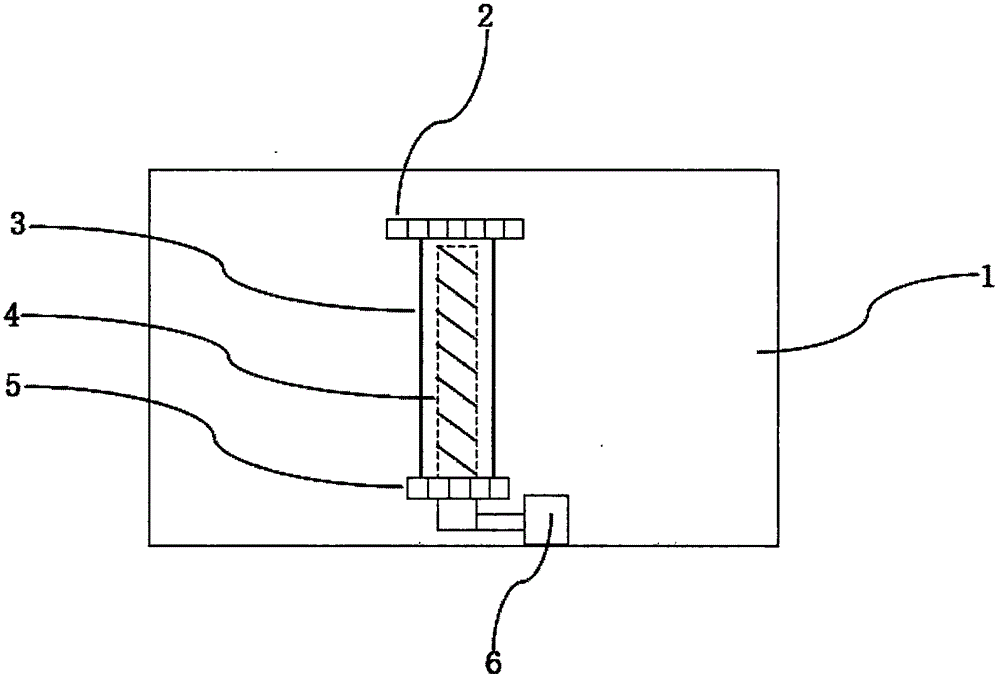

[0009] Such as figure 1 As shown, a kind of central guide tube lifting diversion type hydrolysis tank system of the present invention comprises a hydrolysis tank 1, a guide tube 3 is vertically installed in the center of the hydrolysis tank 1, and a guide tube 3 is arranged in the center of the guide tube 3 A spiral guide column 4, the top of the guide tube 3 has a circle of water outlets 2, and the bottom of the guide tube 3 has a circle of water inlets 5;

[0010] The bottom of the spiral guide column 4 is connected with a waterproof motor 6 .

[0011] A central diversion cylinder lifting diversion type hydrolysis tank system described in this patent, when water distribution is required, the waterproof motor 6 is turned on, and the water treatment agent and sewage mixture at the bottom of the hydrolysis tank 1 enters the diversion cylinder 3 from the water inlet 5 Inside, the high-speed rotating spiral guide column 4 is lifted to the top of the guide tube 3, then sprayed ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com