Large-span fermentation turning machine for organic fertilizer

A technology of organic fertilizer and compost turning machine, which is applied in the direction of organic fertilizer, the preparation of organic fertilizer, and the treatment of biological organic parts, etc. It can solve the problem of high effective utilization rate, achieve uniform spraying, increase the working space and effective utilization rate and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

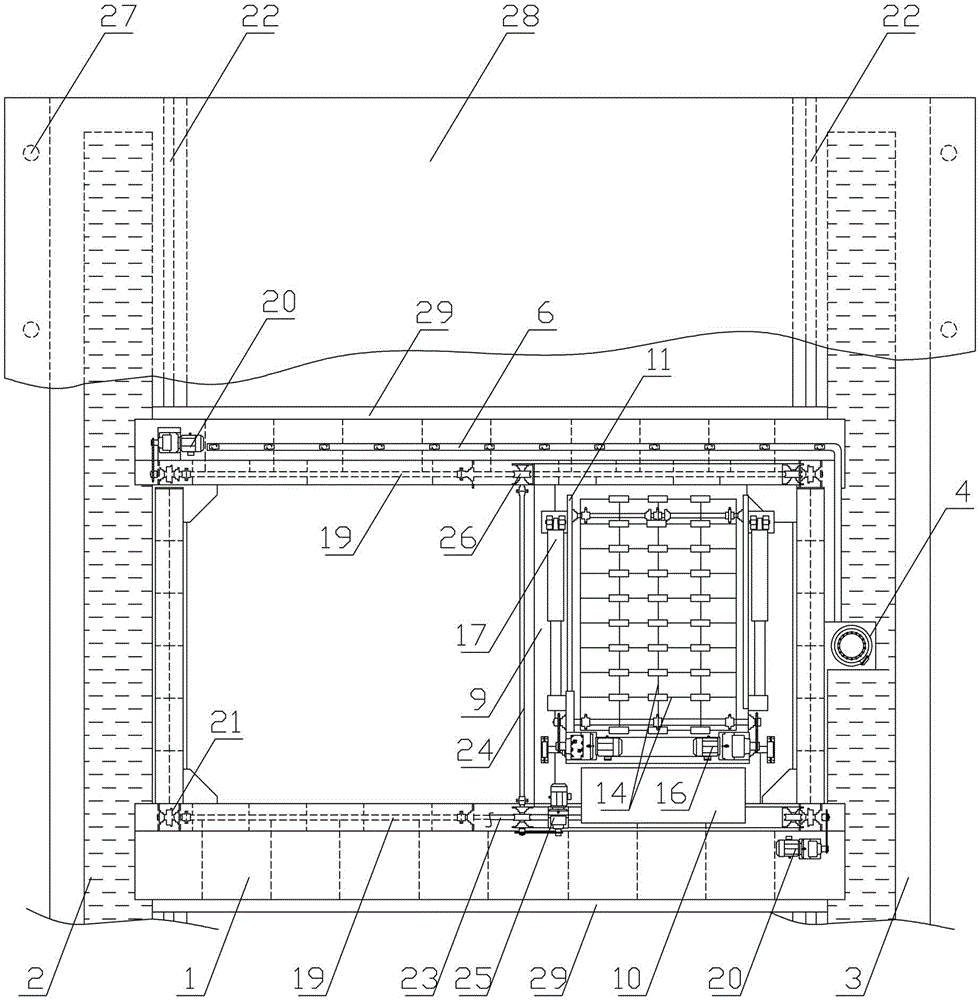

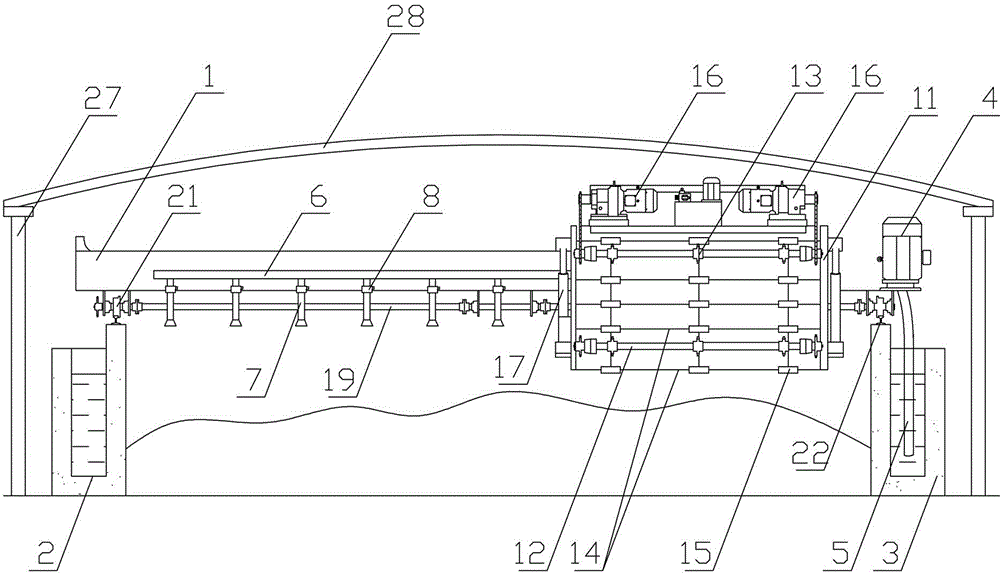

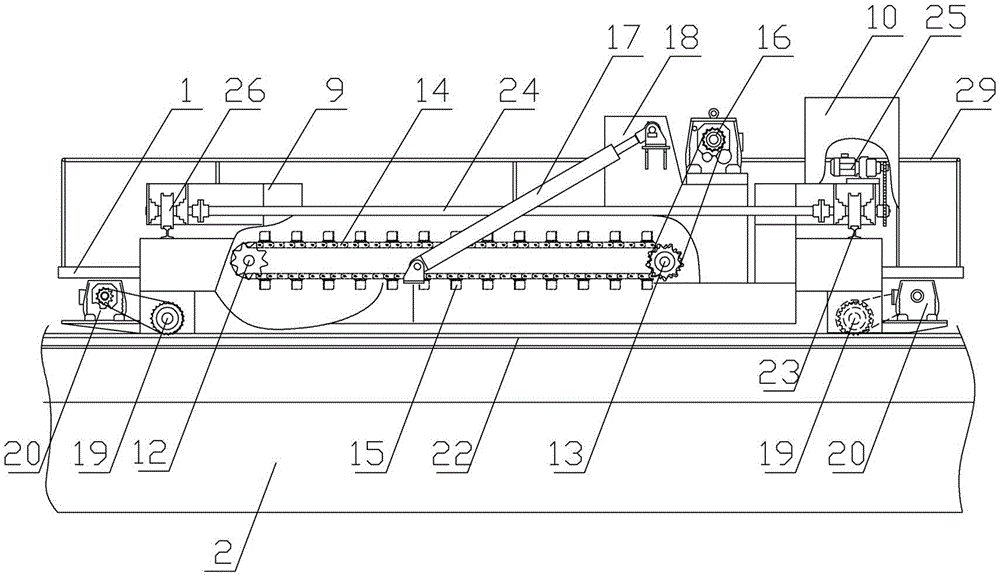

[0022] see Figure 1-3 , the present invention has a rectangular frame 1, and the lower side of the rectangular frame 1 is provided with left and right slurry tanks 2 and 3 arranged longitudinally, and the left and right slurry tanks 2 and 3 form a front and rear open fermentation tank body. Materials for fermentation are placed in the fermentation tank body, and the rectangular frame 1 can move longitudinally along the sides of the left and right slurry tanks 2 and 3; a material pump 4 is installed on the rectangular frame 1, and the feed of the material pump 4 The end is connected to the feed pipe 5, the feed pipe 5 extends into the left slurry tank 2 or the right slurry tank 3, the discharge end of the material pump 4 is connected to the discharge pipe 6, and the discharge pipe 6 is installed on the rectangular frame 1 The underside of one of the transverse beams, and several branch pipes 7 are arranged on the discharge pipe 6, and a solenoid valve 8 is installed on each br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com