Charging method for sunken monocrystalline silicon-like seed crystal melting control

A technology of silicon seed crystal and similar single crystal, which is applied in the field of filling control of the melting control of depressed single crystal silicon seed crystal, to achieve the effect of increasing the temperature and avoiding unmelted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

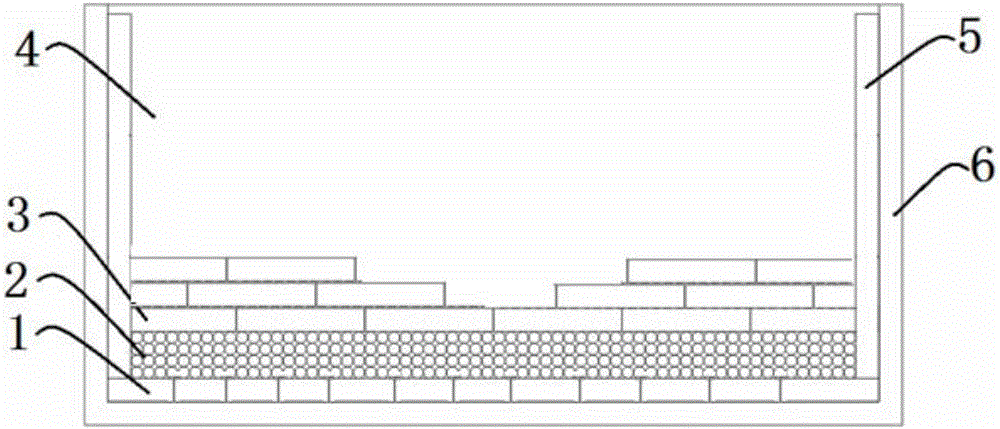

[0023] Such as figure 1 Shown, a kind of charging method of the melting control of concave-like monocrystalline silicon seed crystal comprises the following steps:

[0024] Step a, spraying silicon nitride powder on the inner surface of the quartz crucible 6 for cooling, as a protective layer 5;

[0025] Step b, laying a layer of rapeseed material on the bottom of the quartz crucible 6;

[0026] Step c, laying a seed crystal plate or a seed crystal block on the rapeseed material as the seed crystal layer 1 of the directional solidification semi-melting process;

[0027] Step d, using small particles of primary polysilicon material to fill the gaps between the seed crystal plates or seed crystal blocks laid in the above steps;

[0028] Step e, laying 50mm-100mm rapeseed material on the seed layer 1 as the buffer layer 2;

[0029] Step f, laying 36 crystal bricks made of head and tail materials on the buffer layer 2, as the barrier layer 3, the crystal bricks of the barrier l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap