Production method of rabbit-hair-like villous-fiber fabric

A rabbit plush and fabric technology, applied in the field of textile fabrics, can solve the problems of easy hair loss, no animal plush standing, poor style effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

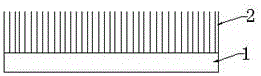

[0024] A rabbit-like plush fiber fabric, which is a warp knitted fabric, comprising a bottom layer 1 and a fleece layer 2, wherein the bottom layer 1 is woven from polyester low elastic yarn with a specification of 50-150D, accounting for 20-40% of the weight of the fabric. %; The fleece layer 2 is woven on the bottom layer 1, and is warp-knitted from polyester super-dull flat yarn with a specification of 150D / 288F, accounting for 60-80% of the weight of the fabric, and the pile height of the fleece layer is 8-25mm. Among them, 150D / 288F polyester super-dull flat yarn has better bulkiness, and the fluff layer of the woven fabric has good bulkiness and excellent standing feeling.

[0025] The fabric is woven from top yarn, middle yarn and bottom yarn on a double-needle bed warp knitting machine according to a special needle-moving process. The specific preparation method includes the following steps:

[0026] (1) Weaving: Use polyester super-dull flat yarn as the top yarn, use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com