Prefabricated grooves for reinforced concrete support beams in deep foundation pits to be demolished by blasting

A technology for reinforced concrete and deep foundation pits, applied in blasting, infrastructure engineering, excavation, etc., can solve problems such as endangering the stability of foundation pit buildings, personal safety accidents, and negative effects of strong blasting, reducing the cost of blasting equipment, The blasting vibration intensity is small, and the blasting and crushing effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention relates to a prefabricated groove for demolishing reinforced concrete support beams of deep foundation pits to be blasted.

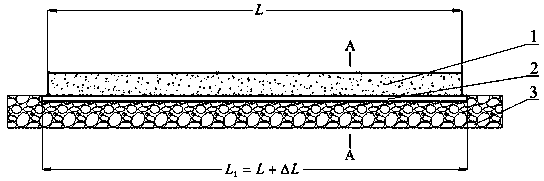

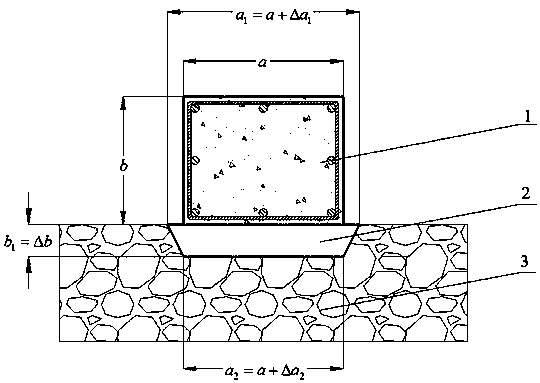

[0033] Such as figure 1 As shown, a prefabricated trench 2 for blasting demolition is excavated in the bedrock 3 directly below the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting, and the longitudinal centerline of the prefabricated trench 2 for blasting demolition is in line with the The longitudinal centerline of the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting is parallel, and the longitudinal centerline of the prefabricated trench 2 for the blasting demolition is parallel to the longitudinal centerline of the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting on the same vertical plane.

[0034] The longitudinal length of the reinforced concrete support beam 1 of the deep foundation pit to be demolish...

Embodiment 2

[0057] The invention relates to a prefabricated groove for demolishing reinforced concrete support beams of deep foundation pits to be blasted.

[0058] Such as figure 1 As shown, a prefabricated trench 2 for blasting demolition is excavated in the bedrock 3 directly below the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting, and the longitudinal centerline of the prefabricated trench 2 for blasting demolition is in line with the The longitudinal centerline of the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting is parallel, and the longitudinal centerline of the prefabricated trench 2 for the blasting demolition is parallel to the longitudinal centerline of the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting on the same vertical plane.

[0059] The longitudinal length of the reinforced concrete support beam 1 of the deep foundation pit to be demolished...

Embodiment 3

[0082] The invention relates to a prefabricated groove for demolishing reinforced concrete support beams of deep foundation pits to be blasted.

[0083] Such as figure 1 As shown, a prefabricated trench 2 for blasting demolition is excavated in the bedrock 3 directly below the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting, and the longitudinal centerline of the prefabricated trench 2 for blasting demolition is in line with the The longitudinal centerline of the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting is parallel, and the longitudinal centerline of the prefabricated trench 2 for the blasting demolition is parallel to the longitudinal centerline of the reinforced concrete support beam 1 of the deep foundation pit to be demolished by blasting on the same vertical plane.

[0084] The longitudinal length of the reinforced concrete support beam 1 of the deep foundation pit to be demolish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com