Ditching machine and its control system

A machine and control box technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of complex construction conditions, labor-intensive excavation, time-consuming, high cost, saving manpower, avoiding casualties, and small width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

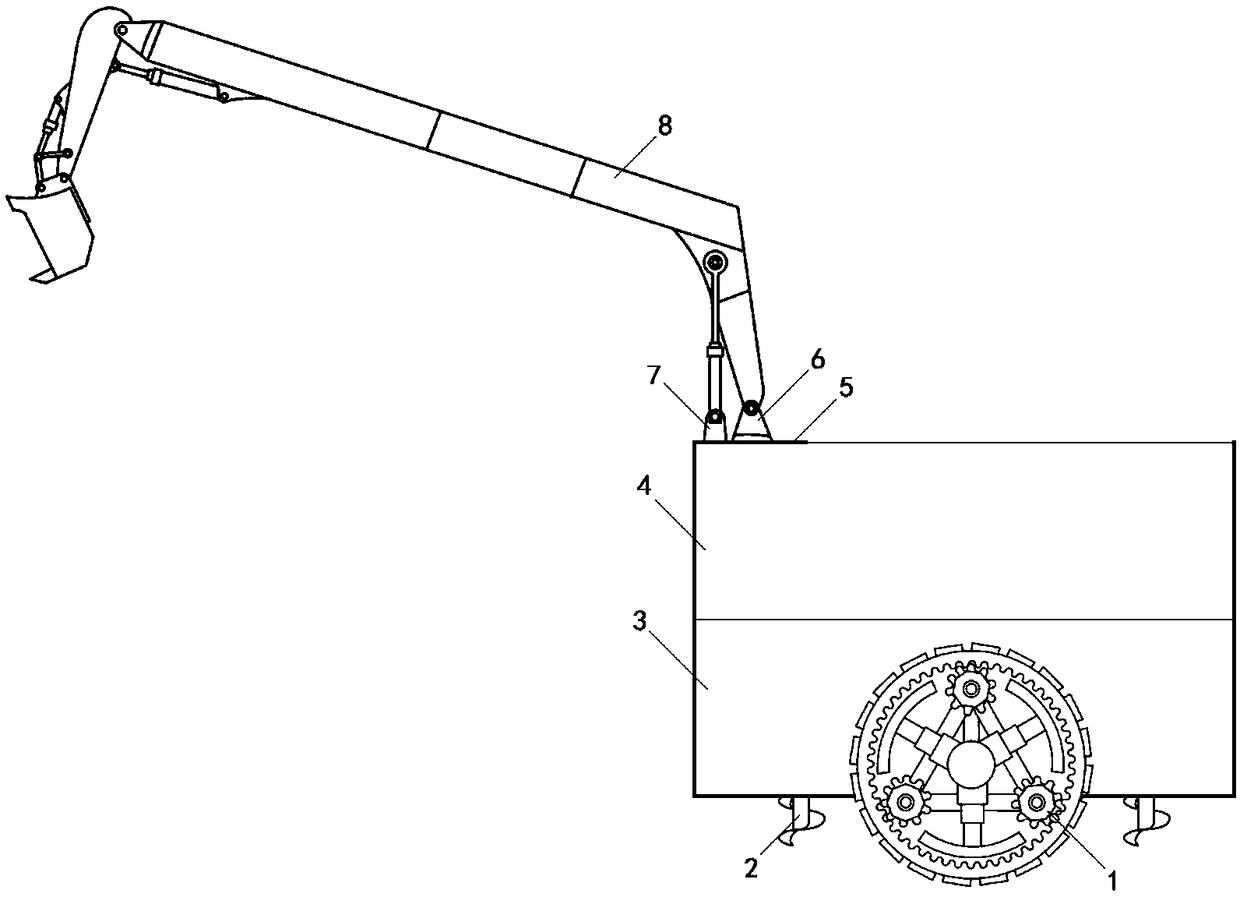

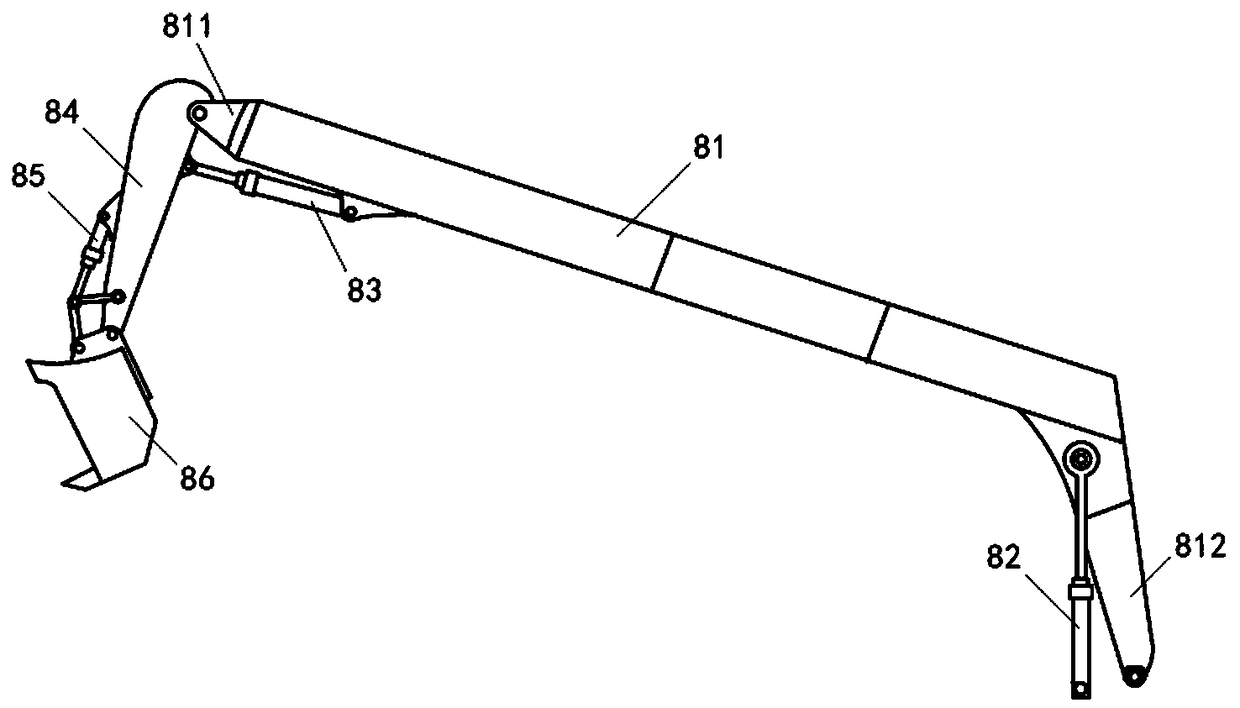

[0055] figure 1 A schematic structural diagram of the ditching machine provided in this embodiment. like figure 1 As shown, the ditching machine of this embodiment includes a control box 3 , an excavating device 8 , a soil loosening device 2 , a traveling device and a soil storage bucket 4 installed above the control box 3 .

[0056] The control box 3 is provided with a control device, a first power device for powering the excavating device 8 and a second power device for powering the traveling device.

[0057] The traveling device is track wheels arranged on both sides of the control box. The track wheel includes a track, a hydraulic support frame for supporting the track, and a first support wheel, a second support wheel, and a third support wheel; internal teeth are formed on the inner side of the track; the first support wheel, the second support wheel, and the third support wheel The wheels are all angle gears, which mesh with the internal teeth on the inner side of th...

Embodiment 2

[0079] This embodiment provides a control system for controlling the operation of the ditching machine, including a remote controller and a control device arranged on the ditching machine; signals are transmitted between the remote controller and the control device through infrared rays or radio waves.

[0080] Wherein, the control device includes a signal receiver, a signal identification unit, a first control signal sending unit and a second control signal sending unit; the signal receiver is used for receiving the remote control signal sent by the remote controller. The signal discrimination unit is used to distinguish the remote control signal as the first remote control signal or the second remote control signal; the first remote control signal is used to control the excavating device to carry out excavation operation; the second remote control signal is used to control the advance and retreat of the traveling device; the first control signal sending unit It is used to sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com