Prefabricated steel-concrete combined beam-column joint structure and its implementation method

A beam-column joint, prefabricated technology, applied in building construction, construction, etc., can solve the problems of difficult to guarantee the quality of wet joints, limited space for prefabrication and assembly rate improvement, and reduce maintenance costs in the later period. , the effect of accelerating the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

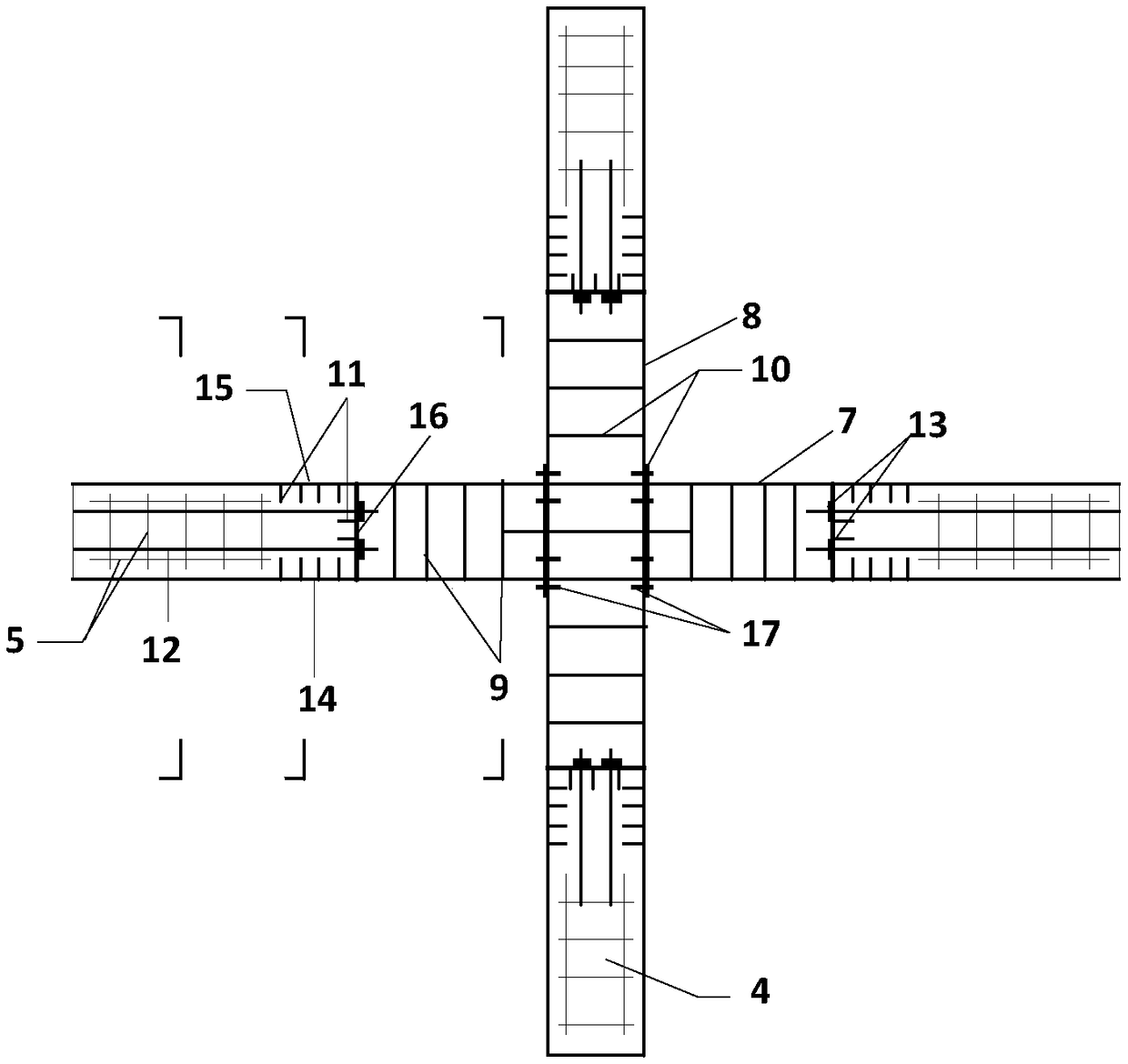

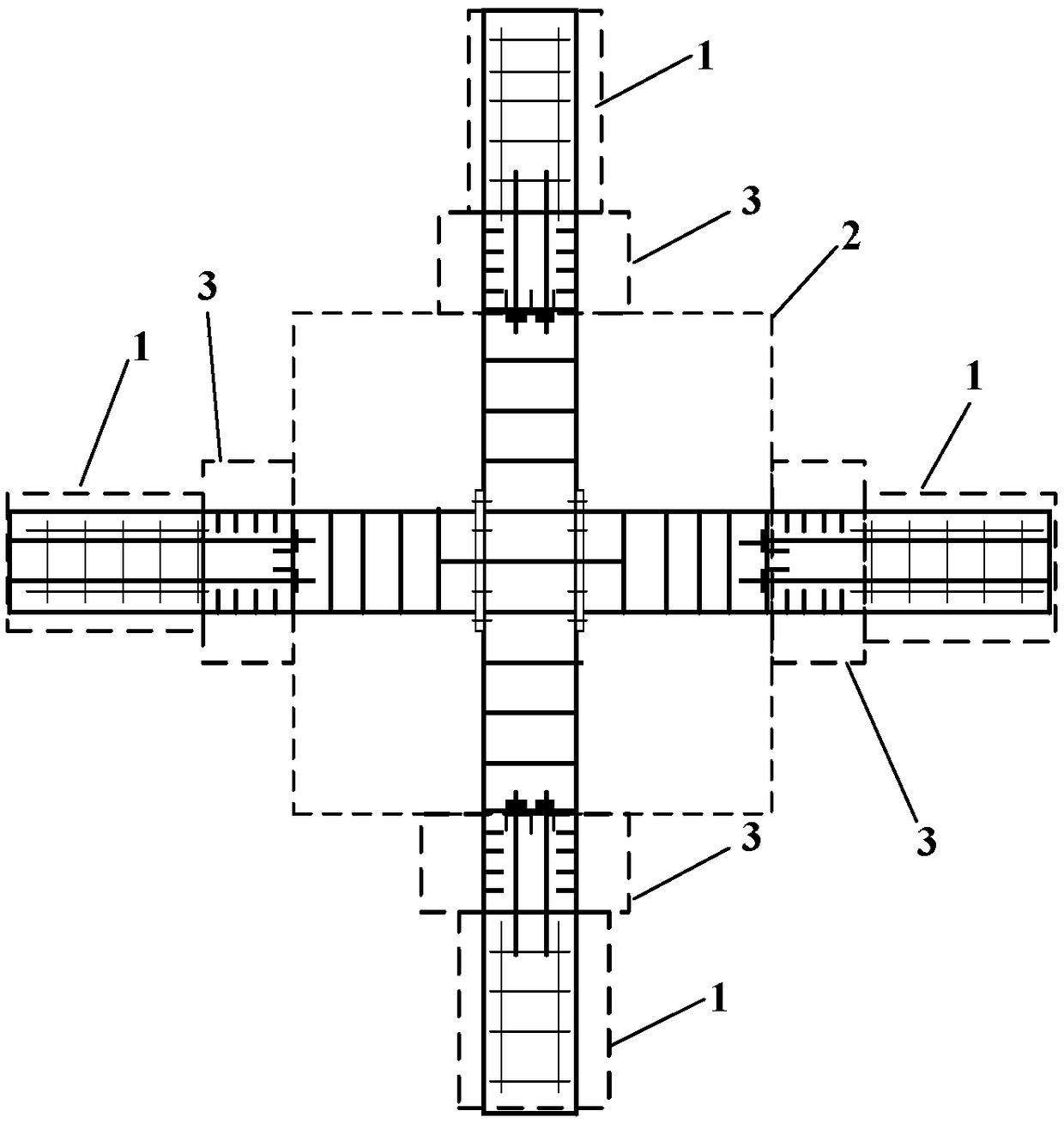

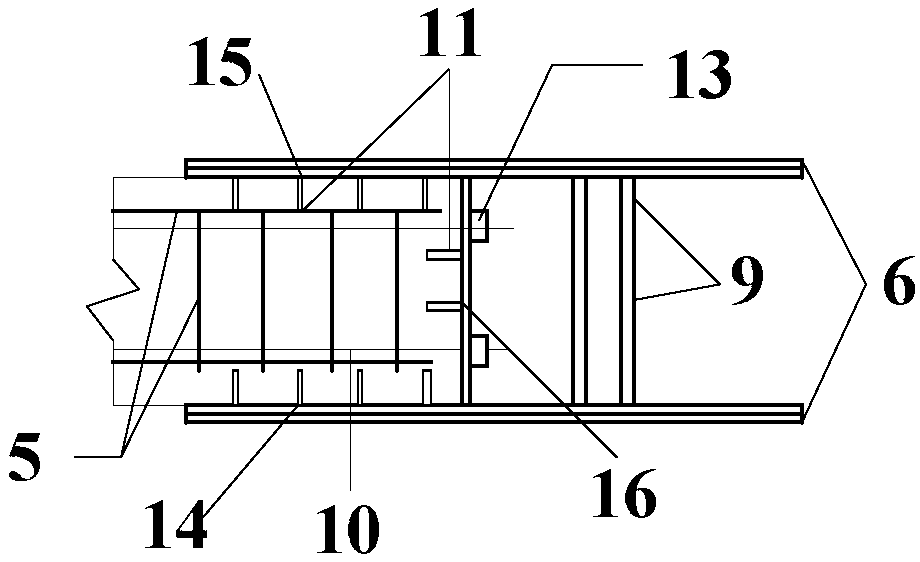

[0048] The layout of concrete structure 1, steel structure 2 and steel-concrete combined section 3 in this embodiment is shown in Figures 1(a), 1(b) and 2. The concrete structure 1 is 2-4 meters long, the beam height is 450mm, the beam width is 250mm, and the column size is 400mm×400mm; The same as the concrete structure; the steel-concrete joint section 3 is composed of concrete 4, steel bars 5, multiple shear keys 11, prestressed cables 12, anchoring system 13, upper steel flange plate 14, upper steel flange plate 15 and lateral steel Composed of end plates 16, the length of steel-concrete composite section 3 is 652mm, the thickness of upper steel flange plate 14, upper steel flange plate 15 and lateral steel end plate 16 of steel-concrete composite section 3 is 20mm, and the shear key The diameter of 6 is 10mm, the key length is 70mm, and the distance between the shear keys 6 is calculated according to the specification.

[0049] The arrangement of the prestressed cable 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com