A hydraulic oil detection and purification system

A technology of purification system and detection system, which is used in fluid pressure actuation system testing, fluid pressure actuation system components, fluid pressure actuation devices, etc. secondary pollution and other problems, to save time, reduce work pressure, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

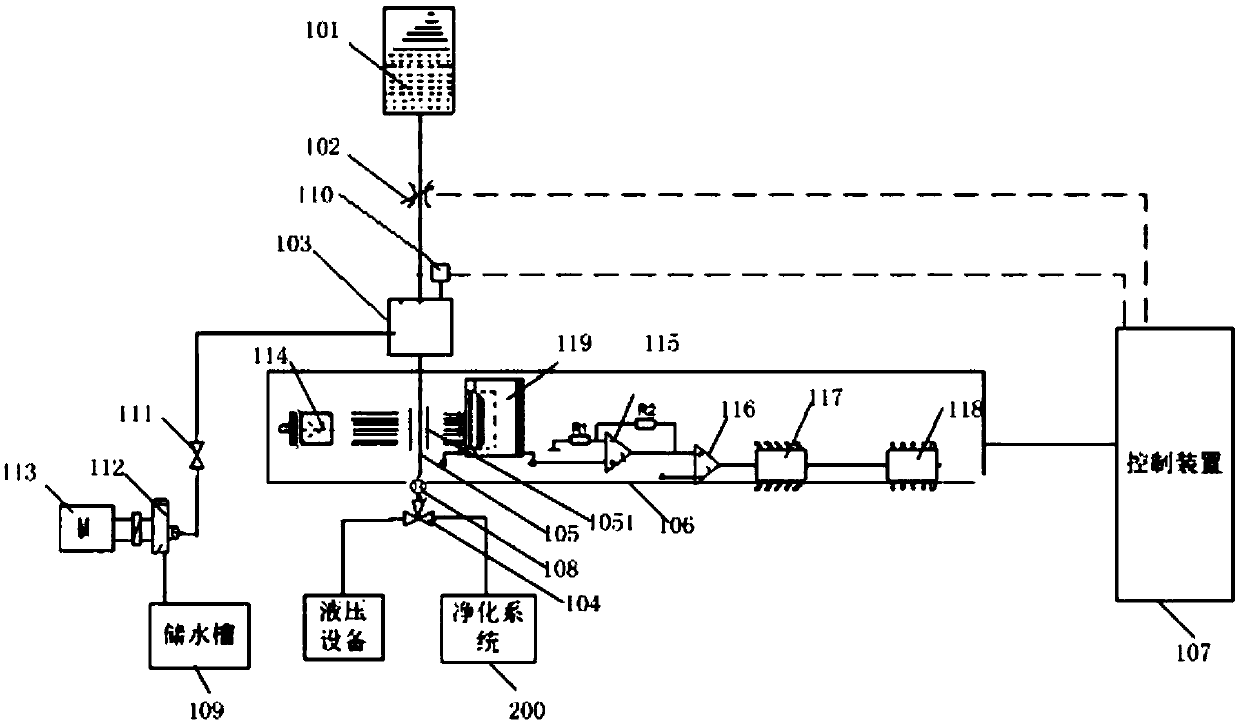

[0021] refer to figure 1 , which is a schematic flowchart of an embodiment of a hydraulic oil detection and purification system of the present invention, the system includes: a hydraulic oil detection system and a hydraulic oil purification system 200 . The hydraulic oil detection system is set at the front end of the hydraulic oil purification system, and the hydraulic oil is divided into the hydraulic oil that can be used directly and the hydraulic oil that needs to enter the hydraulic oil purification system through the hydraulic oil detection system; therefore, the uncontaminated hydraulic oil in this embodiment Hydraulic oil or lightly polluted hydraulic oil can directly enter the hydraulic equipment for use, which simplifies the process, saves time and manpower, and improves work efficiency; in addition, only the heavily polluted hydraulic oil enters the purifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com