Testing device of four-quadrant detecting photoelectric system, and adjusting and testing method

A four-quadrant detection and photoelectric system technology, applied in measuring devices, optical instrument testing, machine/structural component testing, etc., can solve problems such as difficult installation and adjustment of the optical axis, complicated installation and adjustment process, and inability to accurately locate the mechanical axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

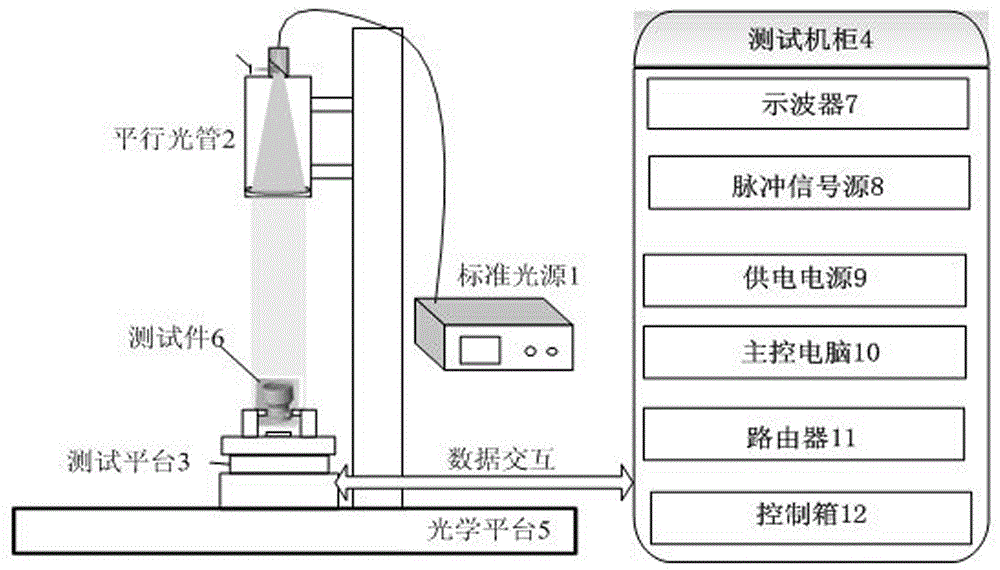

[0025] Such as figure 1 As shown, a test device for a four-quadrant detection photoelectric system, including: a four-quadrant detection photoelectric system and a test cabinet;

[0026] The four-quadrant detection photoelectric system includes:

[0027] Standard light source 1, the standard light source 1 emits a test beam to form a collimated light path through the collimator 2, and irradiates on the test piece 6;

[0028] The test piece 6 is arranged on a test platform 3 provided with a photoelectric receiver;

[0029] The test platform 3 is arranged on the optical platform 5, and the optical platform 5 is calibrated to make it perpendicular to the optical axis of the test beam emitted by the collimator 2;

[0030] The test platform 3 is electrically connected to the test cabinet 4, and receives and execute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com