A device for evaluating gel properties and its evaluation method

A gel and performance technology, applied in the field of devices for evaluating gel performance, can solve the problems of large error, high cost, long cycle, etc., and achieve the effects of reducing errors, improving accuracy, and expanding the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The method for evaluating the gel mechanical properties by using the gel mechanical property evaluation instrument may further comprise the steps:

[0087] 1. Experiment

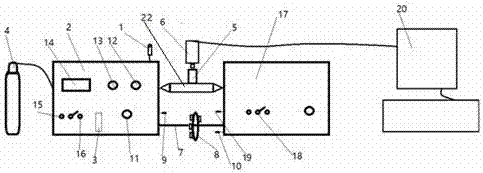

[0088] Start the intelligent controller whose parameters have been set; adjust the pump speed to 8 gears to back up the pump until the back pump light is on; install the capillary filled with gel on the rotating gear, and adjust the direction and speed of rotation without damaging the capillary Place the capillary at a suitable position under the lens; open the nitrogen bottle and start the pneumatic valve to fix and seal the capillary; connect the CCD industrial camera, adjust the microscope so that the gel can be displayed most clearly in the main interface of the software; open the liquid outlet and adjust the pump Speed up to 2nd gear and start the experiment.

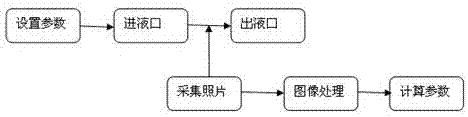

[0089] 2. Data collection

[0090] Set the acquisition speed to 10 sheets / s, click on the screenshot, input the pressure correction v...

Embodiment 2

[0095] 1. Comparison of different measurement schemes

[0096] Sample: Chemical Group No. 3 Gel

[0097]

[0098] 2. Processing steps

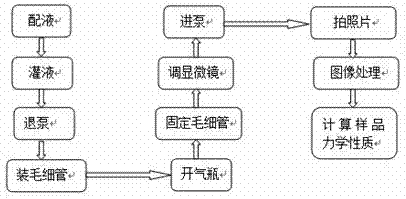

[0099] 1) Experiment preparation

[0100] Open the nitrogen bottle, start the gel intelligent analyzer, open the gel intelligent analysis software, load the gel sample, adjust the microscope and CCD industrial camera.

[0101] 2) Collect data

[0102] Adjust the pump speed to 2nd gear, input the pressure correction value, turn on the pump, click to start capturing pictures, start collecting data, click to stop capturing pictures, stop capturing pictures and write the data into the database.

[0103] 3) Data processing

[0104] Enter the length of the gel, click Auto Analysis, and the software automatically processes the data.

[0105] 4) Drawing data analysis

[0106] Draw pressure-time curve, gel deformation curve, elastic modulus curve, viscosity curve.

[0107] 3. Processing results

[0108] 1) Total data

[0109]

[0110] 2) D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com