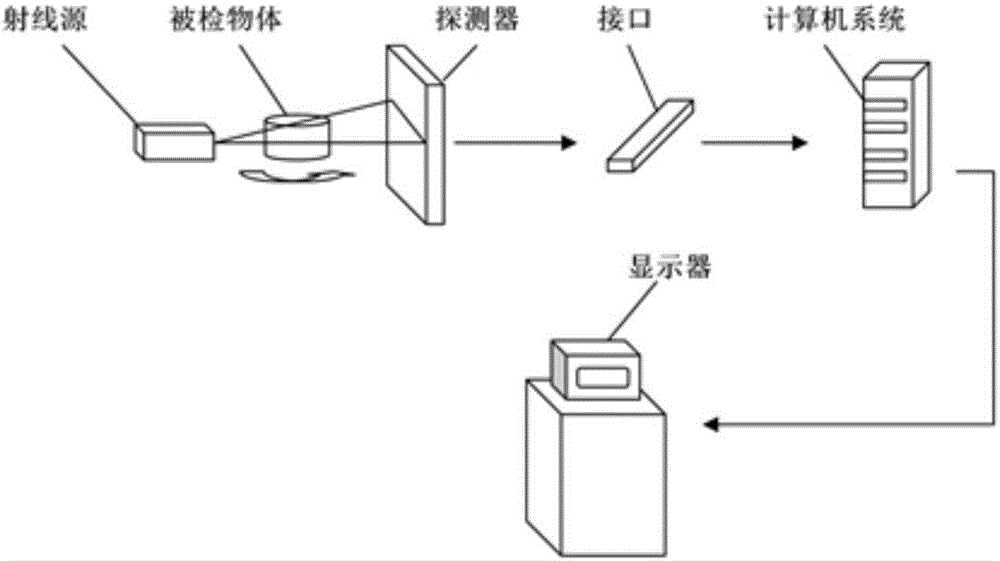

Core X-ray scanning testing experimental method

An experimental method and scanning testing technology, which are applied in the field of X-ray scanning testing of cores, can solve the problems of bulky instruments, high radiation intensity, and great harm to human body, and achieve simple device structure, overcome ray hardening, and reduce harm to human body. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

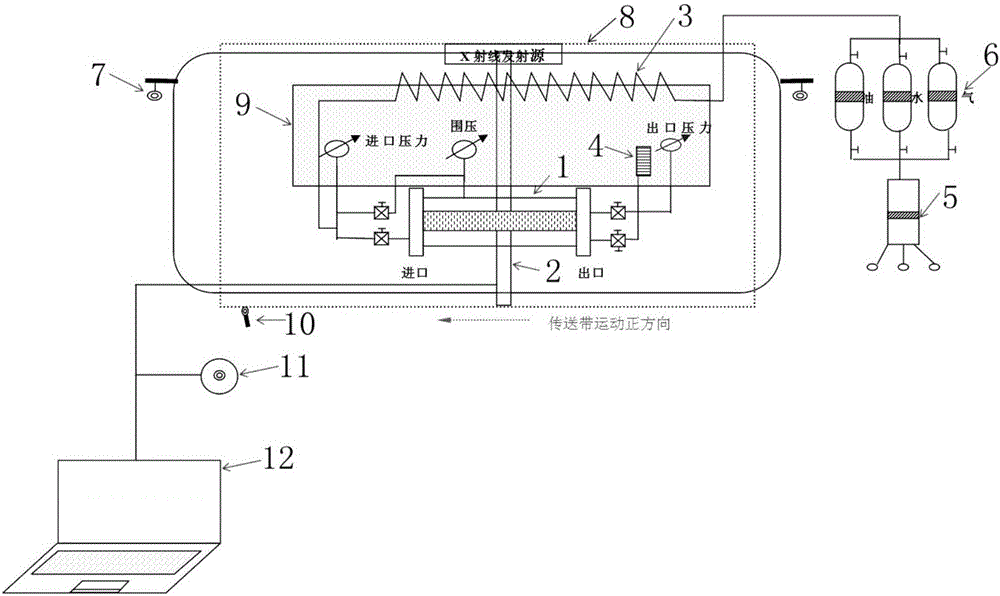

[0046] Such as Figure 2 ~ Figure 3 As shown, a kind of rock core X-ray scanning test experimental method described in the present embodiment comprises the following steps:

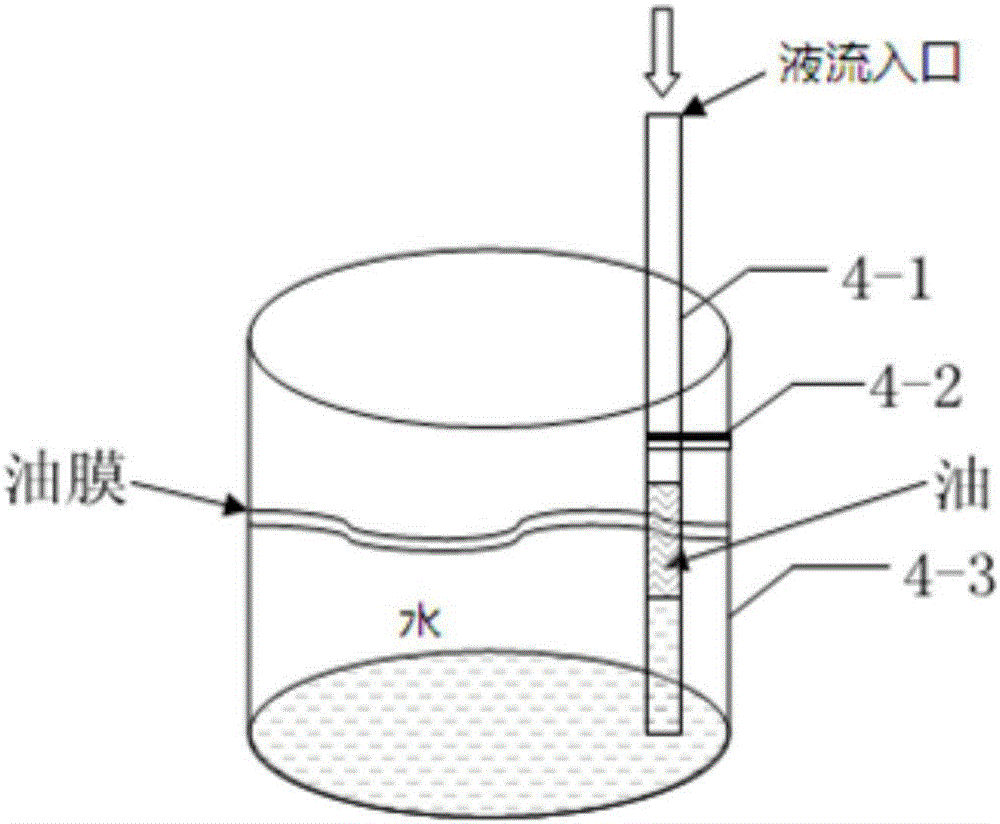

[0047] S1. Saturated formation water: install the core holder 1 on the conveyor belt, connect the pipeline, use the displacement pump 5 to apply confining pressure to the core holder through the intermediate container 6, and after the confining pressure is loaded, the core holder 1 and The pipeline is evacuated to saturate the formation water. After the saturation of the formation water is completed, the one-button push switch 11 is pressed, and the core holder 1 moves with the conveyor belt. After the core holder 1 enters the X-ray emitting and receiving device 8, the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com