Anti-condensation control method for power equipment box

A technology of power equipment box and control method, which is applied in the direction of non-electric variable control, adaptive control, general control system, etc. It can solve the problems that the dehumidification effect is difficult to meet the demand, condensation is easy to occur, and the terminal box catches fire, etc., so as to reduce the transformation Risk reduction, reduction in engineering volume, and the effect of preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

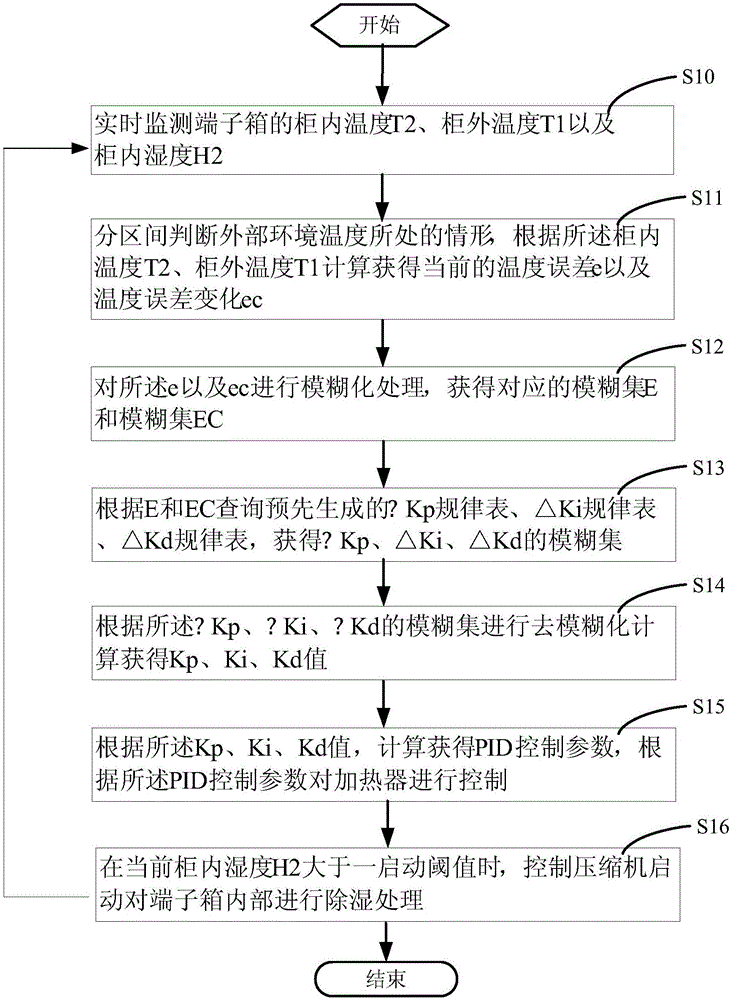

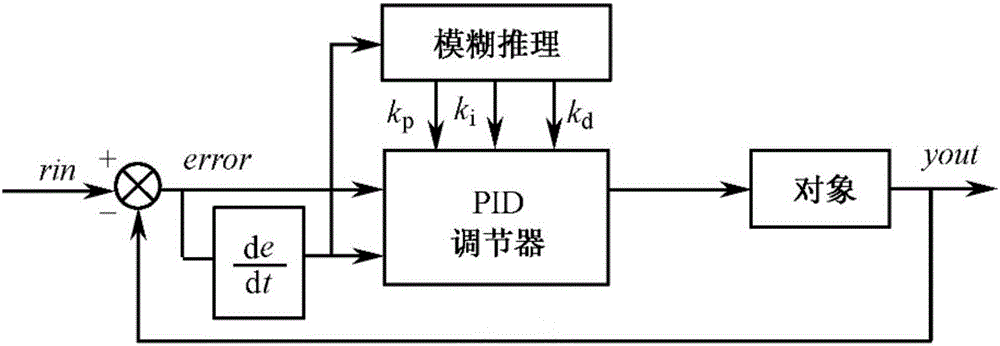

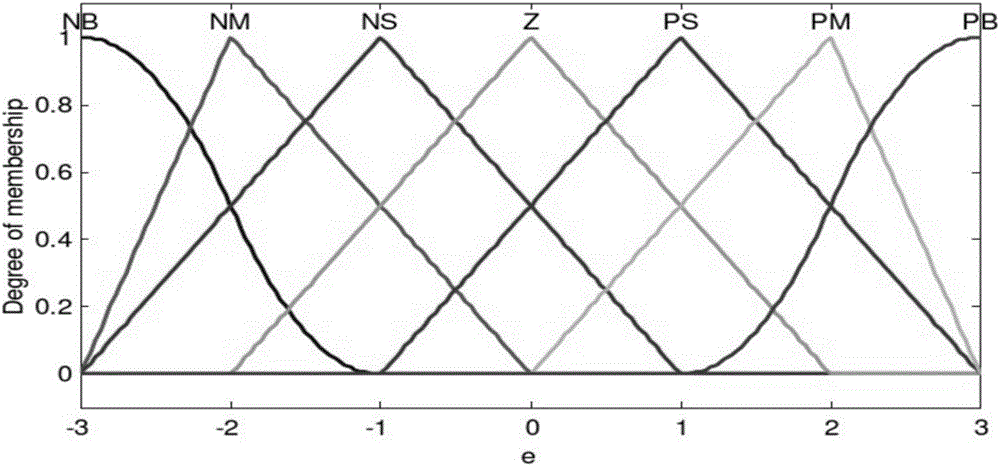

[0040] Such as figure 1 As shown in FIG. 1 , it shows a schematic flow chart of an embodiment of an anti-condensation control method for a power equipment box provided by the present invention. please combine Figure 2 to Figure 9 As shown, in this embodiment, the anti-condensation control method of the electrical equipment box includes the following steps:

[0041] Step S10, obtain the temperature T2 inside the cabinet and the temperature T1 outside the cabinet of the terminal box in real time through the temperature sensors installed inside and outside the power equipment box; obtain the humidity H2 inside the cabinet through the temperature sensor;

[0042] Step S11, judge the situation of the external environment temperature in different regions, calculate and obtain the current temperature error e and temperature error change ec according to the temperature T2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com