Comprehensive Construction Method of Engine Shell Vibration Profile Diagram

A technology of engine casing and construction method, applied in design optimization/simulation, instrumentation, calculation, etc., can solve problems such as poor practicability and achieve good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

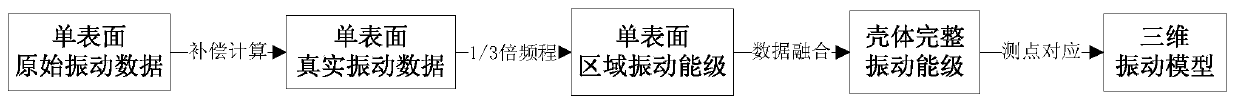

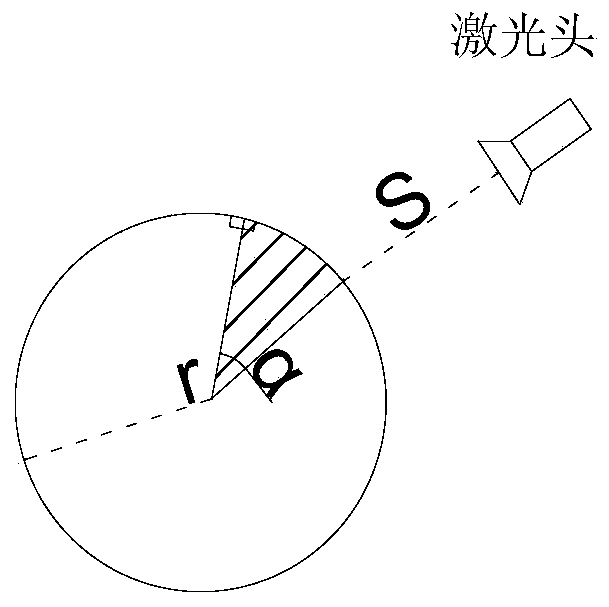

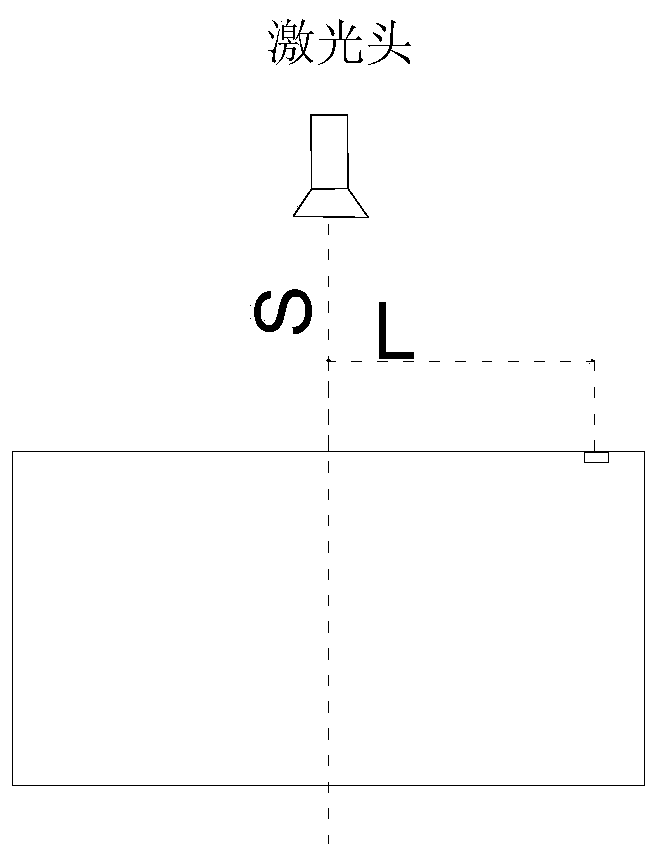

[0043] refer to Figure 1-3 . In this embodiment, for a cylindrical engine with a casing, the operating conditions are simulated by using the cold-state dragging method of the motor, and the vibration data obtained by the laser surface vibration instrument are used. Due to the limitation of the fixed support method during the test, the measurement object (engine casing) was divided into 4 surfaces, and the vibration data of the casing at the same speed were collected in 4 times, and the vibration of the casing was analyzed and synthesized based on the original information. The specific steps of the comprehensive construction method of the overview map and the vibration overview map of the engine casing are as follows:

[0044] a. Assuming that the laser head scans the entire surface of the shell in n times, the raw data collected each time is a set of time domain series of each point in each area Among them, n(i) represents the i-th measuring point of the n-th surface;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com