Soft sensor modeling method of correlation vector machine based on dynamic weighting of triangle angle value

A correlation vector machine and dynamic weighting technology, applied in CAD numerical modeling, computer-aided design, instruments, etc., can solve the problems of not being able to reflect the dynamic characteristics of the industrial production process in real time, and the measurement accuracy is not high enough, so as to improve the generalization ability and measurement accuracy. The effect of good real-time performance and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

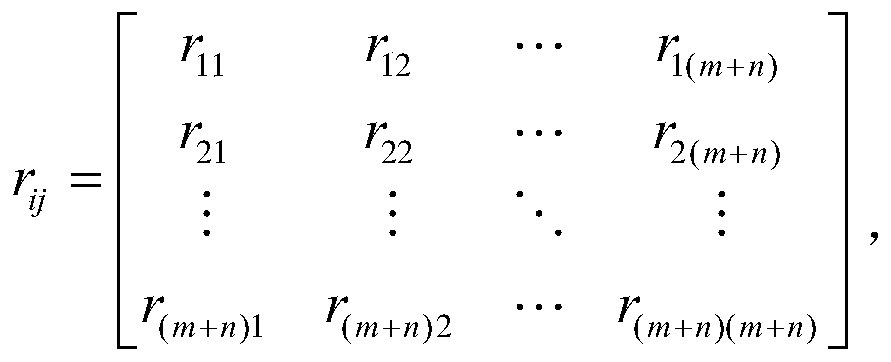

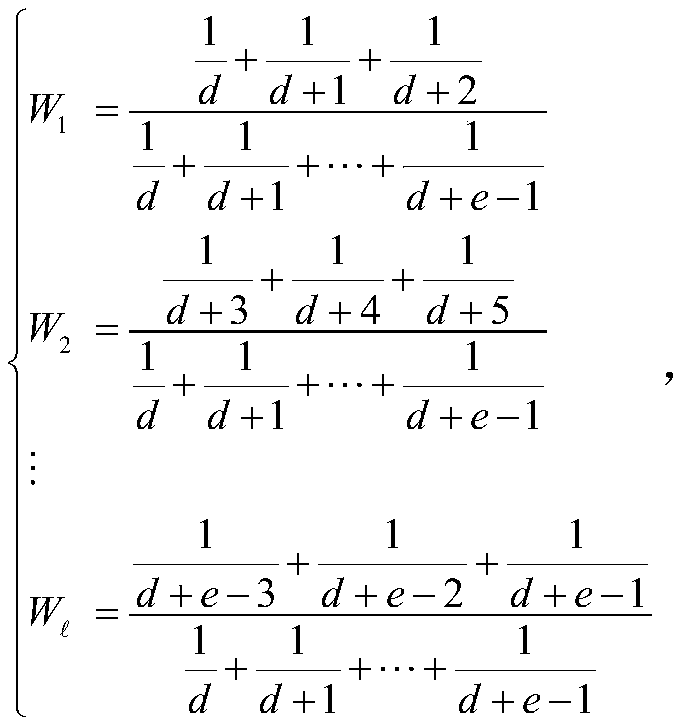

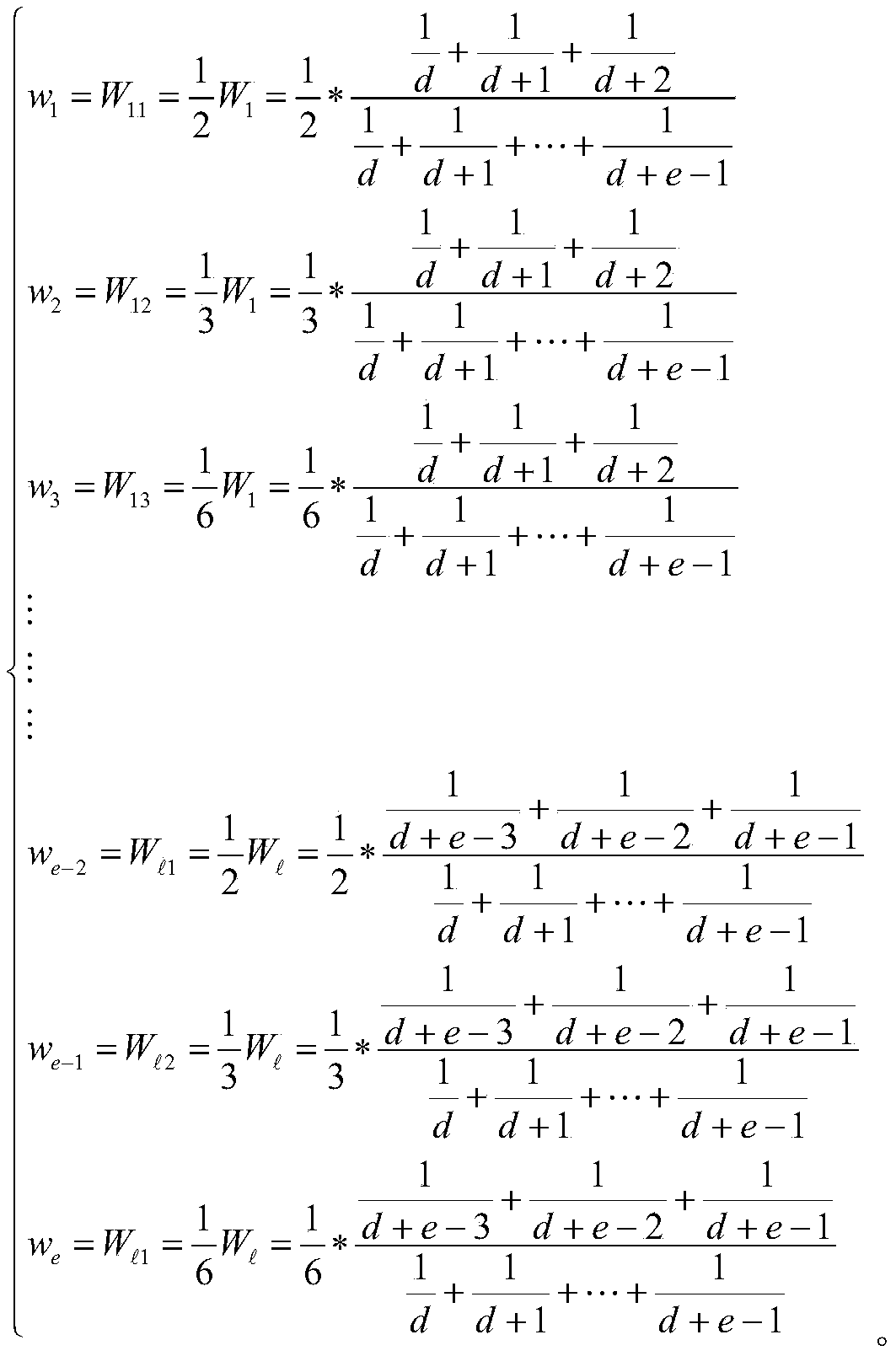

[0014] Aiming at the actual needs of the industrial production process, the present invention adopts various corresponding physical instruments to collect the measurement data of various environmental variables in the actual industrial production process. For example, in the field of biological fermentation, various sensors are used to collect temperature, dissolved oxygen, pH, The measurement data of partial pressure of oxygen, partial pressure of carbon dioxide, rotational speed, pressure, glucose concentration, lactic acid concentration and cell density, etc., obtain the environmental variable data sample set I, I={I i ∈ R m}, where i=1,2,...,m, where I represents the sample set composed of all environmental variables, i represents the i-th environmental variable, m is the number of environmental variables, R is a real number, R m is the m-dimensional real number sample space. The collected data samples are stored in the historical database as soft measurement modeling sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com