Priori knowledge-based method for monitoring fault of magnesite electric melting furnace by kernel flexible manifold embedding

An electric fused magnesia furnace and prior knowledge technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of insufficient use of process monitoring and difficult for workers to achieve, and achieve the realization of processing and fault diagnosis. , avoid data disaster, the effect of flexible model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

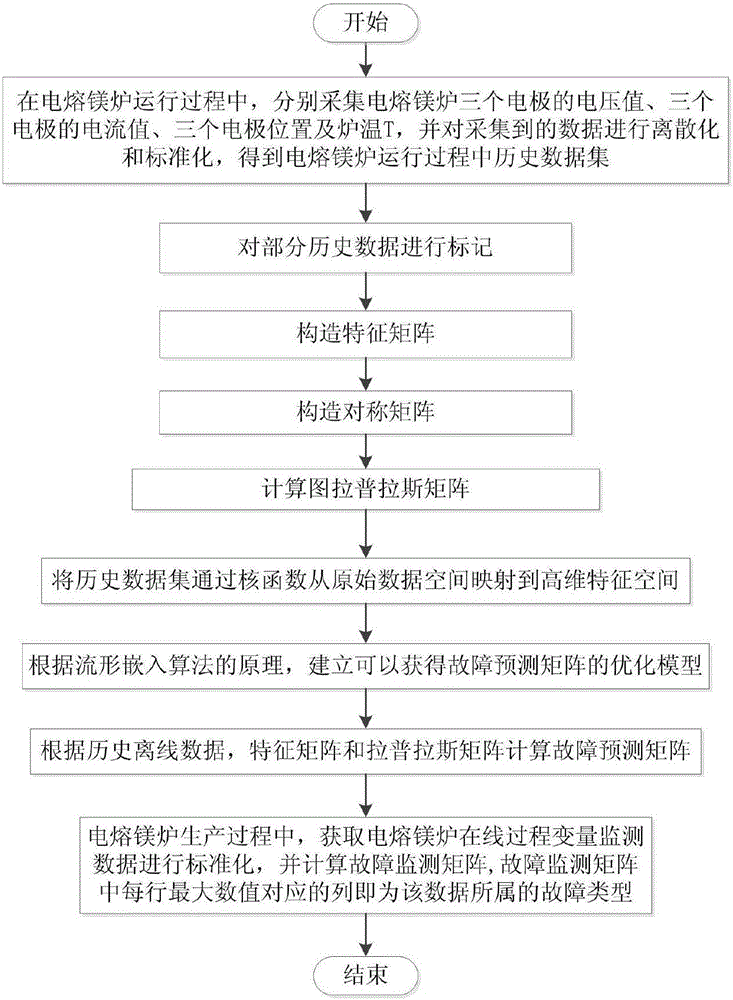

[0031] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] like figure 2 As shown, the kernel flexible manifold embedded fused magnesium furnace fault monitoring method based on prior knowledge includes the following steps:

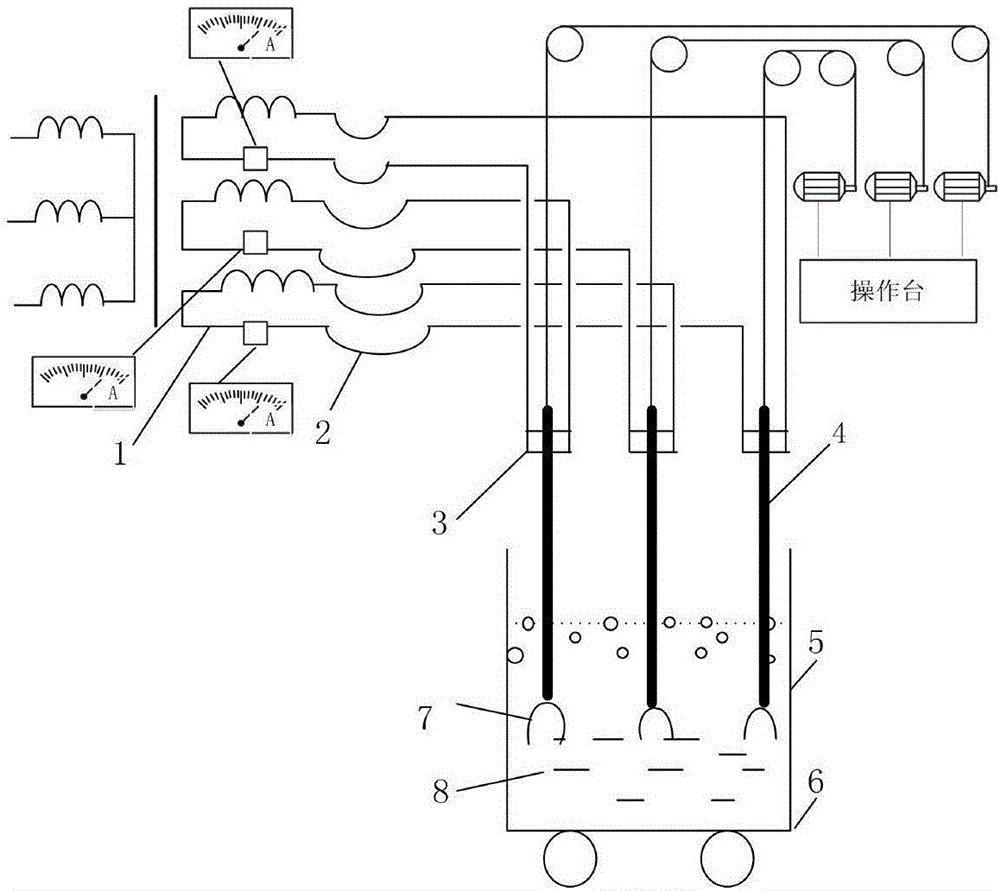

[0033] Step 1: During the operation of the fused magnesium furnace, respectively collect the voltage values UA, UB, UC of the three electrodes of the fused magnesium furnace, the current values IA, IB, IC of the three electrodes, and the positions of the three electrodes PA, PB, PC and furnace temperature T, and discretize and standardize the collected data to obtain the historical data set X=[x 1 ,x 2 ,...,x i ,x i+1 ,...,x n ]∈R f×n , where x i is historical data, n is the number of data samples, f is the number of variables, i=1, 2,..., n;

[0034] Step 2: According to the changes in variables in the data and the relationship between variables, the old workers can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com