A flexible nano-triboelectric generator, its preparation method and the fabricated sensor

A nano-friction and generator technology, which is applied to the preparation method and the sensor produced, and the field of flexible nano-friction generators, can solve the problems of generators that are difficult to package, stretch, twist, and wearable devices, etc., and achieve the preparation method Simple, good elastic properties, strong wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

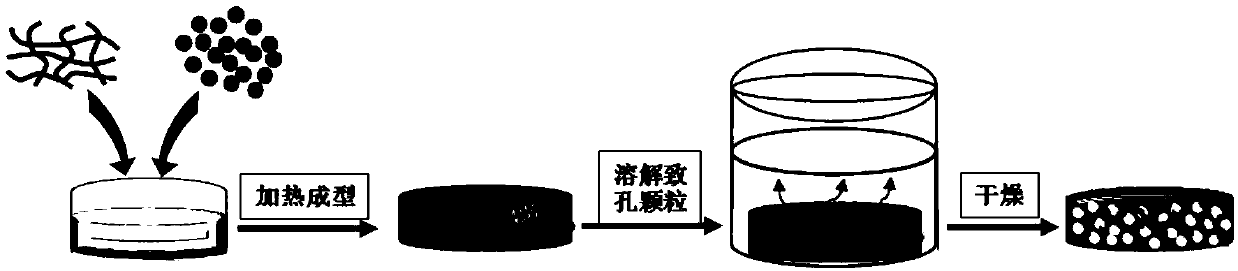

[0047] Such as Figure 1a Shown is a simplified flow chart of the preparation of the flexible porous nano triboelectric generator, and the specific preparation method includes steps:

[0048] Disperse the nano conductive material in the dispersant to form a suspension, which can be ultrasonically dispersed for 1-2 hours.

[0049] The dispersed nano conductive material suspension is uniformly mixed with the curable flexible polymer material main agent to obtain a mixed composite material liquid. Wherein, the weight ratio of the nano conductive material to the curable flexible polymer material is preferably 1:4-19.

[0050] After the dispersant in the mixed composite material liquid is evaporated, a curing agent is added and mixed uniformly to obtain a mixed material. The temperature of the evaporation process can be changed to 50-100°C.

[0051] Add the soluble granules to the mixed material and mix well. Wherein, the particle size of the soluble particles is 100 μm-1 mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com