Cable stranding rolling wheel device with automatic distance adjustment

An automatic adjustment and rolling wheel technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of reduced manufacturing cost, unstable processing quality, high maintenance cost, etc., to reduce the impact on equipment and stabilize processing quality Reliable and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

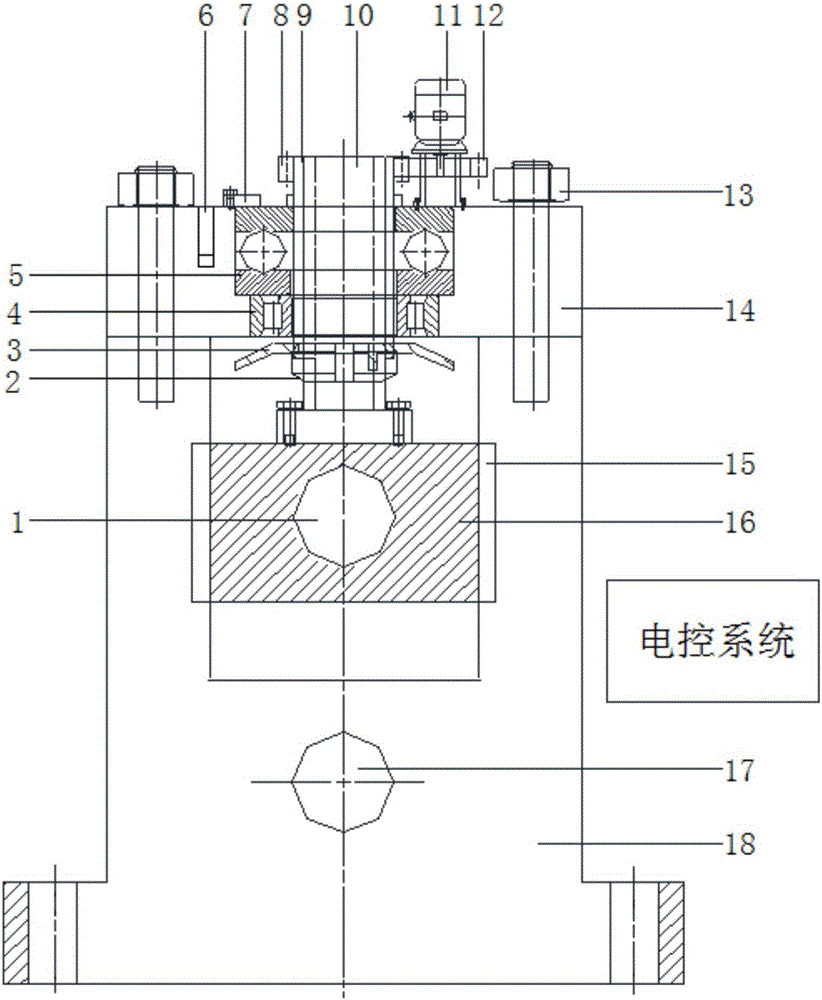

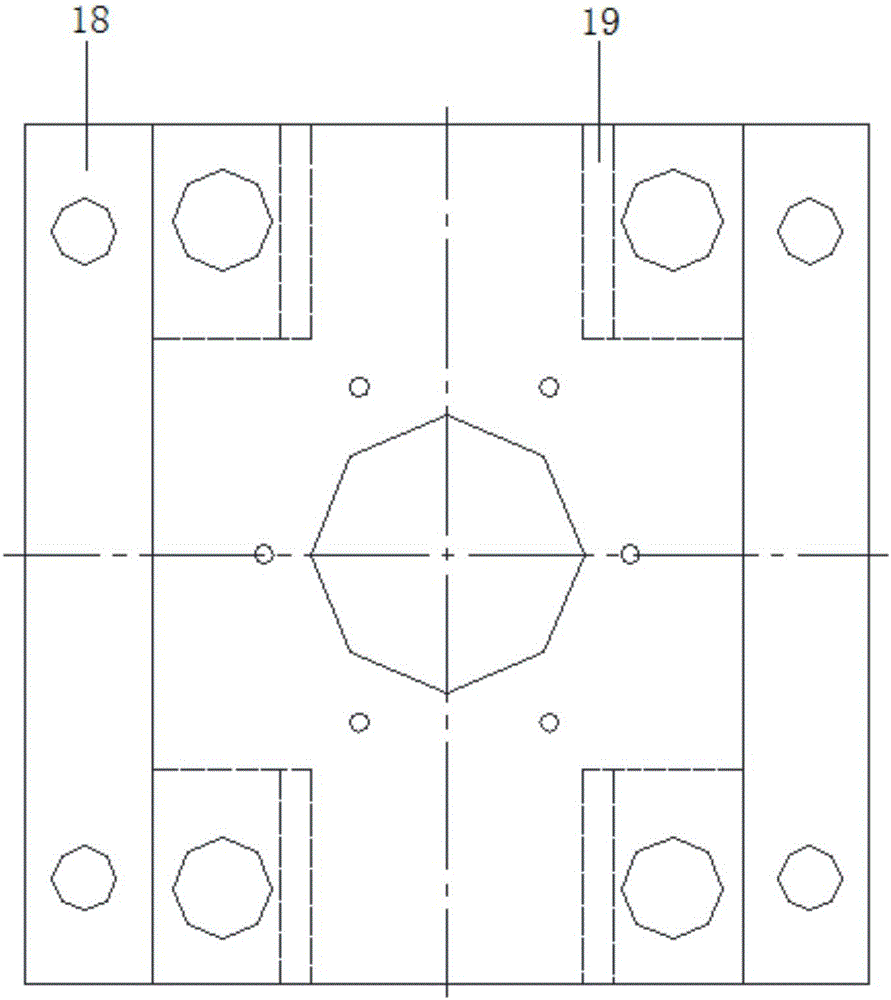

[0029] With reference to accompanying drawing, the present invention is realized like this: a kind of automatic distance adjustment cable strand rolling wheel device, it comprises electric control system, second gear 8, ball nut 9, ball screw mandrel 10, servomotor 11, the first A gear 12, upper rolling wheel fixed frame 16, rolling wheel base 18 and guide rail seat 19; The output shaft of described servo motor 11 is provided with first gear 12, and the second gear 12 on this first gear 12 and ball screw nut 9 The gear 8 is meshed and driven; the guide rail seat 19 is symmetrically distributed on both sides of the rolling wheel base 18, the servo motor 11 is placed upside down on the upper part of the second gear 8, and the ball screw 10 is vertically arranged in the ball screw nut 9; When the electric control system controls the operation of the servo motor 11, the ball screw nut 9 can be driven to rotate through the gear transmission, thereby driving the ball screw 10 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com