Chip monitoring device and method for flip-chip process

A chip mounting and chip technology, which is applied in the field of chip flip-chip process chip monitoring devices, can solve the problems of difficult positioning, undetectable damage, hidden dangers, etc., and achieves the effect of reducing production failure rate, precise control, and enhanced visibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

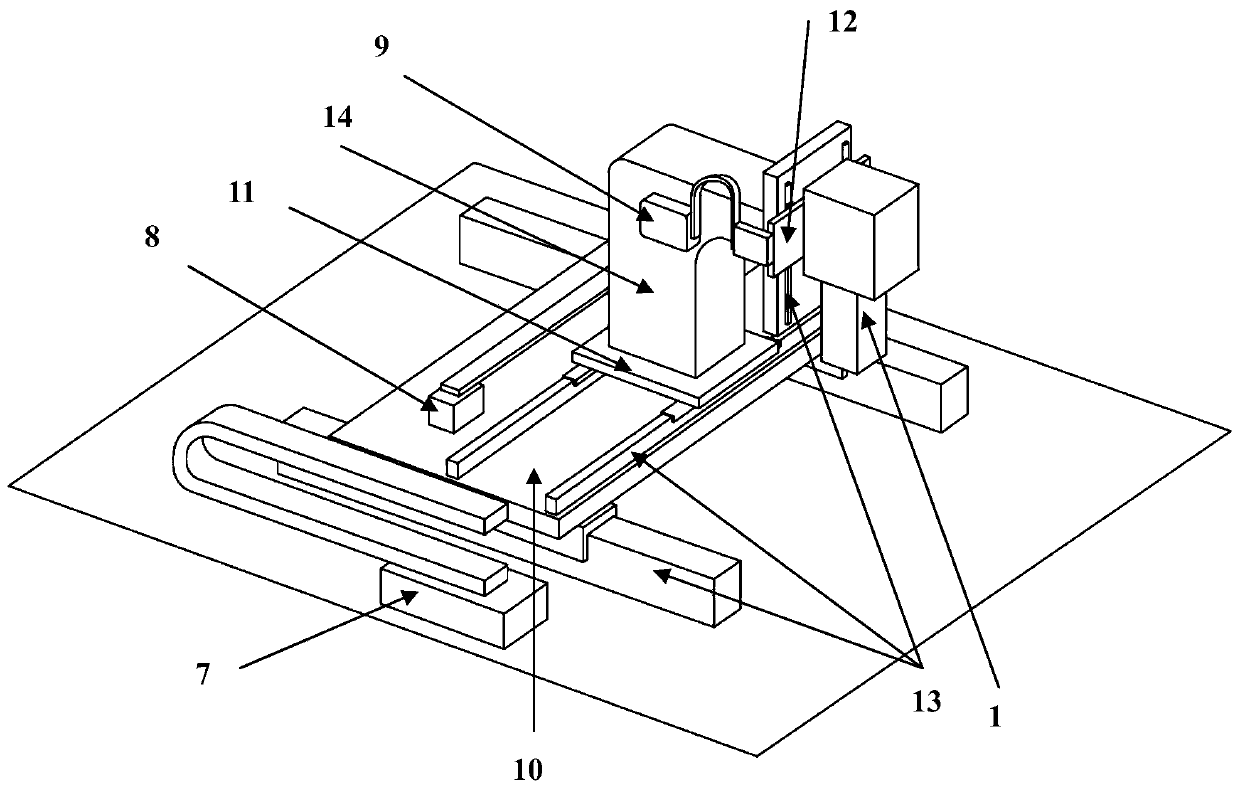

[0033] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

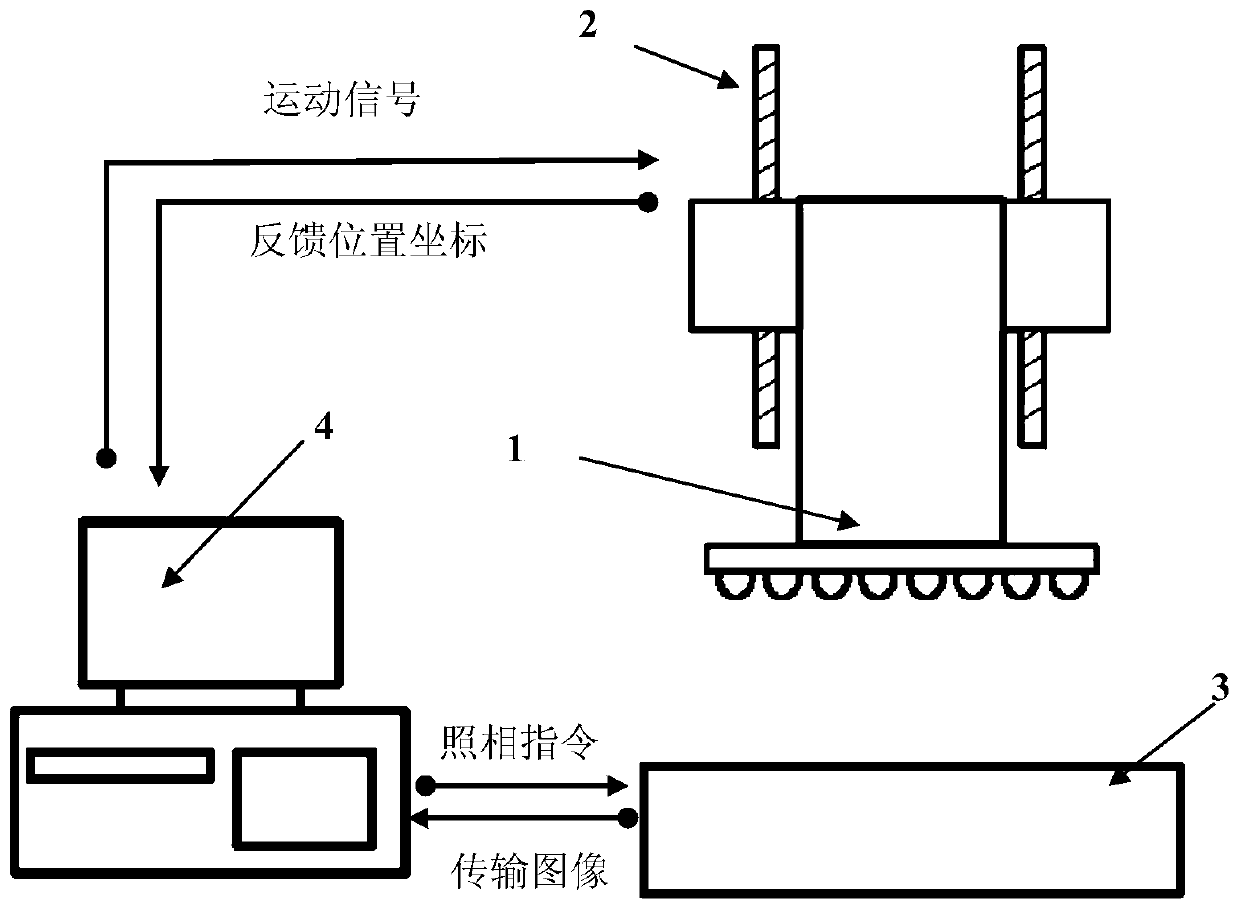

[0034] Such as figure 1 As shown, the present invention provides a chip monitoring device for a flip-chip process, which is composed of a chip mounting head 1 , a moving mechanism 2 , a photographing device 3 and a control computer 4 . in:

[0035] The chip mounting head 1 is vertically and fixedly installed on the moving mechanism 2, and is used for absorbing chips with bumps;

[0036] The moving mechanism 2, driven by the motion control signal of the control computer 4, drives the chip placement head 1 to move horizontally or vertically;

[0037] The photographing device 3 is fixedly placed on a horizontal plane, and its photographing camera faces vertically upwards, receives the amplification control signal sent by the control computer 4, takes pictures of the bump surface of the chip according to the amplification control signal, obtains the image informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com