Novel electrical control system for horizontal forging machine

An electrical control system and technology of flat forging machines, applied to the driving device of forging presses, etc., can solve the problems of high consumption of human resources, high processing costs of flat forging machines, and the inability to guarantee the personal safety of staff, so as to improve efficiency and The effect of accuracy rate, labor intensity reduction and processing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

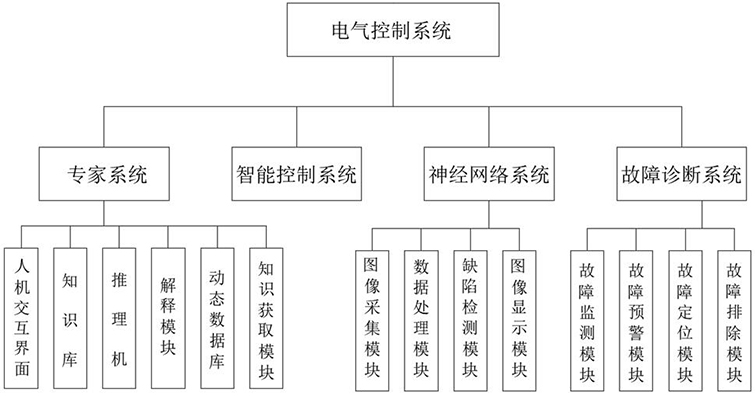

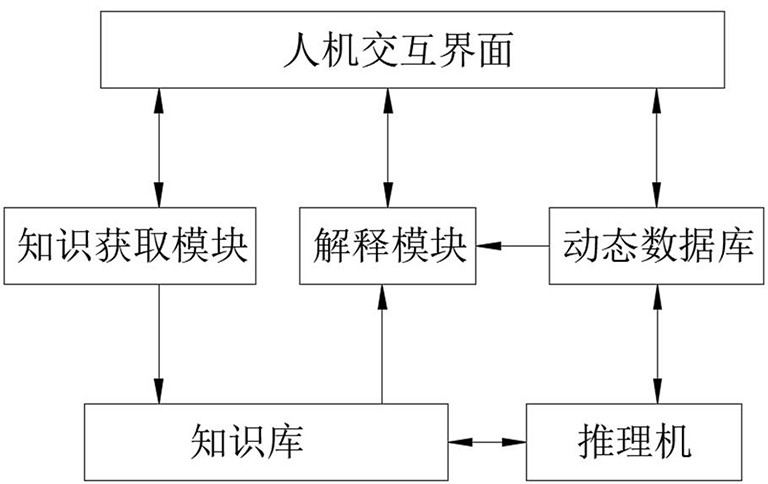

[0017] see Figure 1~2 , in an embodiment of the present invention, a novel electrical control system for flat forging machines includes an intelligent control system, a fault diagnosis system, an expert system and a neural network system, and the neural network system includes an image acquisition module, a data processing module, a defect detection module and The image display module and the image acquisition module are used to collect the visual images of the forgings being processed by the flat forging machine, and send the collected images to the data processing module in the form of data signals, so that the forging conditions of the forgings can be monitored in real time. The data processing module is used to receive the data signal information sent by the image acquisition module and the defect detection module. The defect detection module is used to collect the surface conditions of the forgings in real time, perform defect detection, defect location and defect classif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com