Control device and method for reducing commutation torque ripple of brushless direct-current motor

A brushless DC motor and control device technology, applied in torque ripple control, electronic commutator and other directions, can solve the problems of reducing the commutation torque ripple of brushless DC motor, unable to eliminate torque ripple, etc. Reduced commutation torque ripple and simple angle calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

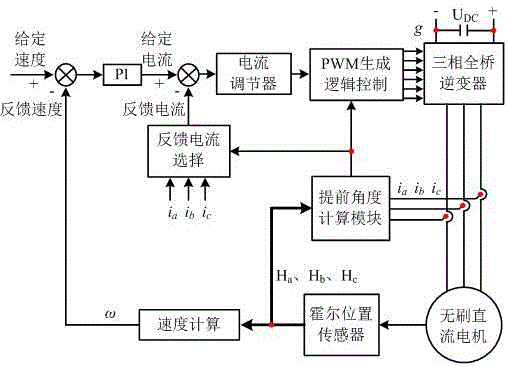

[0059] Such as figure 1 Shown is a block diagram of a brushless DC motor speed and current double closed-loop control system including the method of the present invention. It consists of brushless DC motor, three-phase full-bridge inverter, Hall position sensor, PWM generation and logic control, feedback current selection, current regulator, speed calculation, speed PI adjustment and advance angle calculation module. Among them, the Hall position sensor is installed on the brushless DC motor, and outputs the three-phase Hall position signal H a 、H b 、H c To the speed calculation module and the advance angle calculation module, the speed calculation module outputs the mechanical angular velocity ω of the motor rotor rotation; the given speed is subtracted from the actual feedback speed of the motor to obtain the speed error, and then the PI regulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com