Micro-channel aluminum vapor chamber

A technology of micro-channel and soaking plate, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. Effects of low temperature icing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

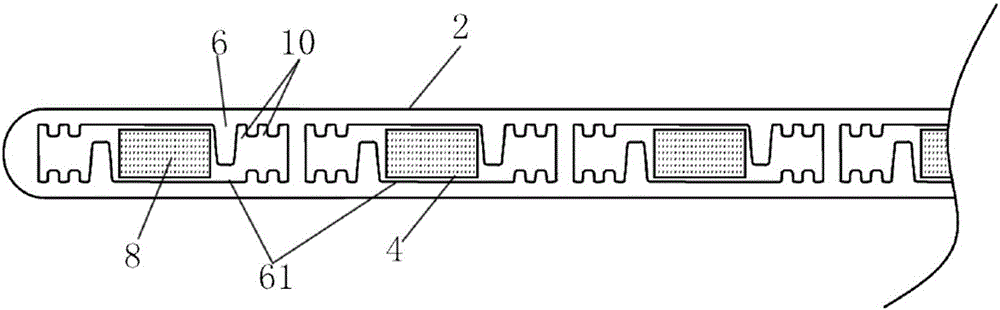

[0021] Such as figure 2 As shown, a microchannel aluminum vapor chamber is disclosed in this embodiment, which includes a header 2, and a closed vacuum liquid collecting space is formed inside the collecting pipe 2, and a phase change working medium is filled in the liquid collecting space, and the collecting The tube 2 is provided with several tube sheets 4 spaced apart from each other along the direction of its length extension. The above-mentioned tube sheets 4 are aluminum sheets, and each tube sheet 4 is provided with microchannels. The microchannel network structure, the channel width and channel wall thickness are about 50um, and the channel aspect ratio is about 10; the phase change working medium circulates in the microchannel, evaporates at the evaporation end and heats the liquid working medium on the outer surface of the microchannel, and the working medium The mass phase change forms a vapor-liquid boundary to generate suction force, which provides power for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com